48

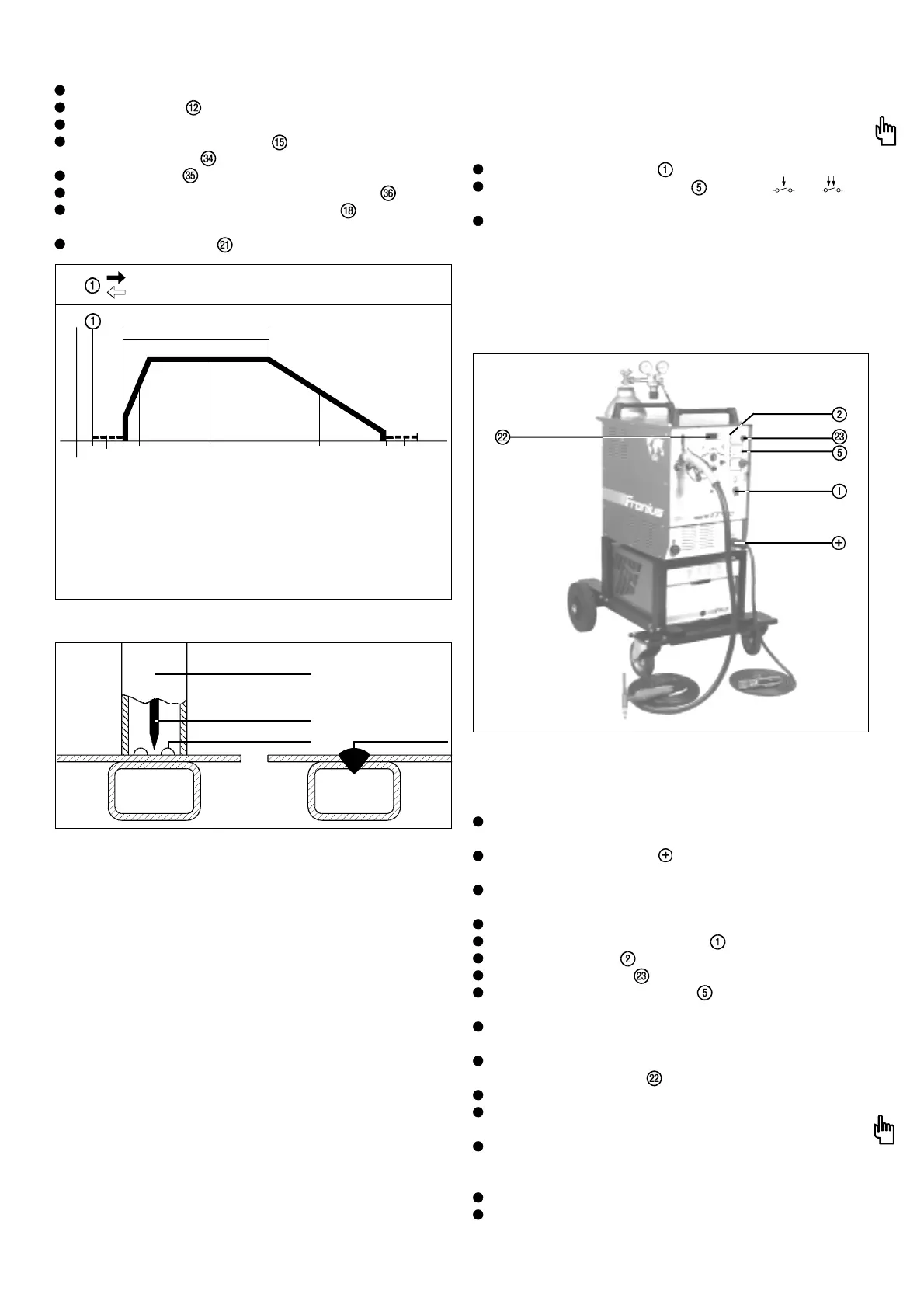

The automatic spot-welding sequence is as follows:

Pull back and release the torch trigger.

Gas pre-flow time elapses.

Arc ignites with start-arc current.

Current rises via the set up-slope to the spot-welding current

value set on the dial

.

LED control lamp lights up.

The spot-welding time (0,5 - 8 secs.) set on the dial elapses.

The current drops via the down-slope (dial ) to a minimum

current value of 8 A over the speed set, and then switches off.

The gas post-flow time elapses.

TIG WELDING WITH HIGH-FREQUENCY

IGNITION (HF) - START UP

WARNING! When the TRANSTIG is being used for TIG

welding, the manual electrode cable will always be live

when:

the mains master switch is ON

the functional selector switch is in the or

position and

when the “start welding” signal has been given from the

torch trigger.

Make sure, when the manual electrode cable is not in use,

that it is either disconnected from the machine or else

fastened to the machine in such a way (insulated) that the

electrode holder and the coated electrode cannot touch any

electrically conductive or earthed parts such as the housing,

gas cylinder, workpiece etc.

I

O

I

H

t

H

t

End of welding

Gas post-flow time

Start of cycle

Gas pre-flow time

Arc ignition

Current-rise via up-slope

Spot-welding with set welding

current I

H

in conjunction

with spot welding time t

H

Current-drop

via down-slope

Pull back and release the torch trigger

Fig. 35

Spot-welding gas nozzle

Tungsten electrode

Spot-weldGas discharge opening

Fig. 36

Note! In the event of any trouble, the welder can manually

interrupt the automatic spot-welding sequence by pulling back

and releasing the trigger again!

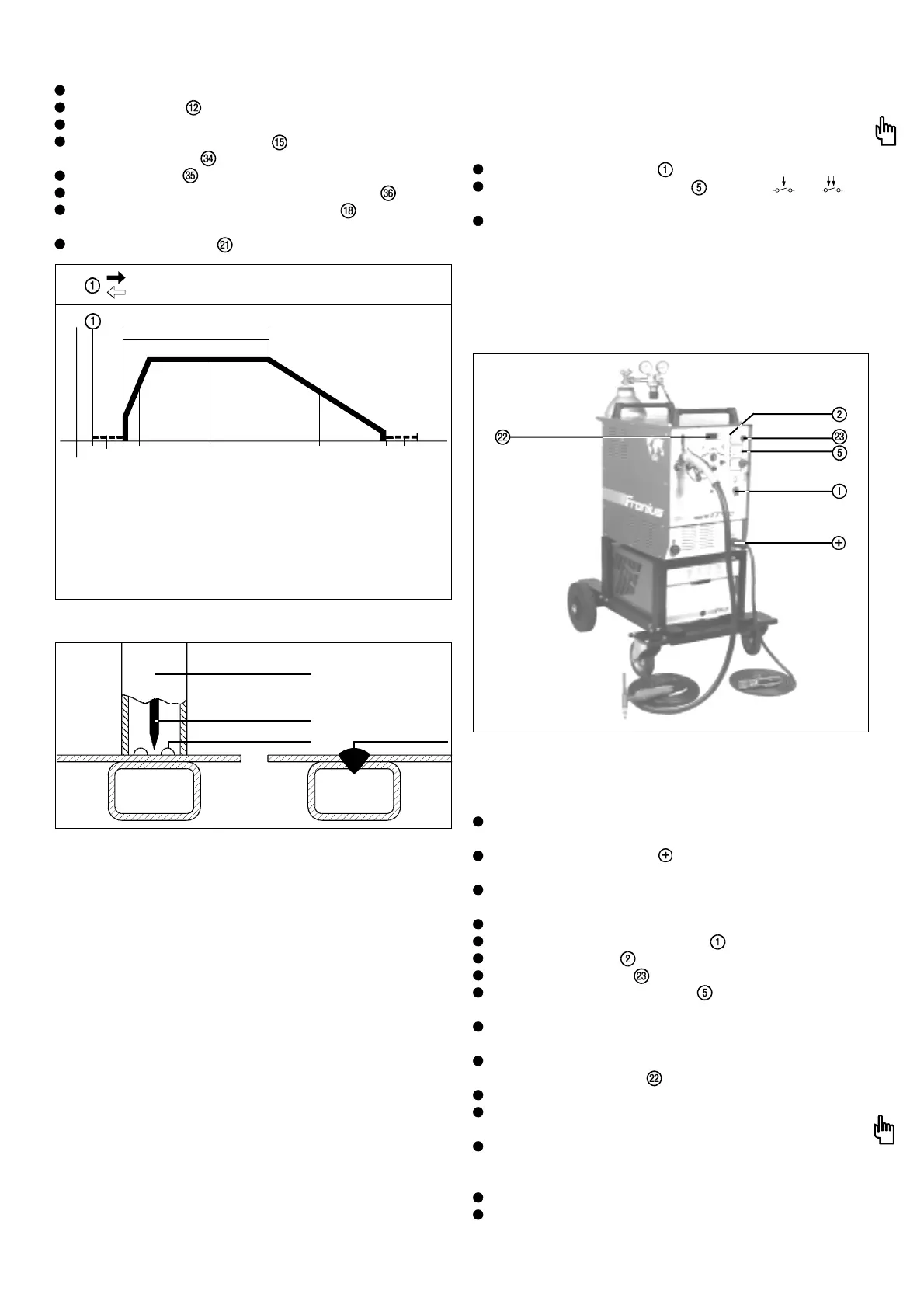

Fig. 37 Transtig water-cooled: TIG welding machine consisting of power

source with control unit, FK 7 cooling unit, manual torch, earth cable,

gas cylinder with pressure regulator.

Setting up

Fit the mounted torch with a tungsten electrode and a gas

nozzle (see the instruction manual for the torch concerned).

Plug the earth cable into the current socket and latch in place

firmly.

Connect the gas hose from the machine to the gas pressure

regulator.

Plug in the mains plug.

Switch on the mains master switch -

- mains control lamp lights up.

Set HF-selector switch to the "1" position.

Shift the function selector switch into the 2-step or 4-step

position, as required; respective LED lights up.

If necessary, connect a remote control unit (see description of

remote control operation on p. 42).

Select welding parameters (command value for main current I

H

is displayed on ammeter ).

Open the gas cylinder valve by turning it anticlockwise.

Pull back the torch trigger and release it (4-step operation)

Warning! High-frequency ignition is now switched on !

Turn the setscrew on the underside of the gas pressure

regulator in a clockwise direction until the working manometer

shows the required flow-rate in litres/min.

Set the gas pre-flow and post-flow times on the power source.

Pull back and release the torch trigger once again

(= welding OFF)

Loading...

Loading...