67

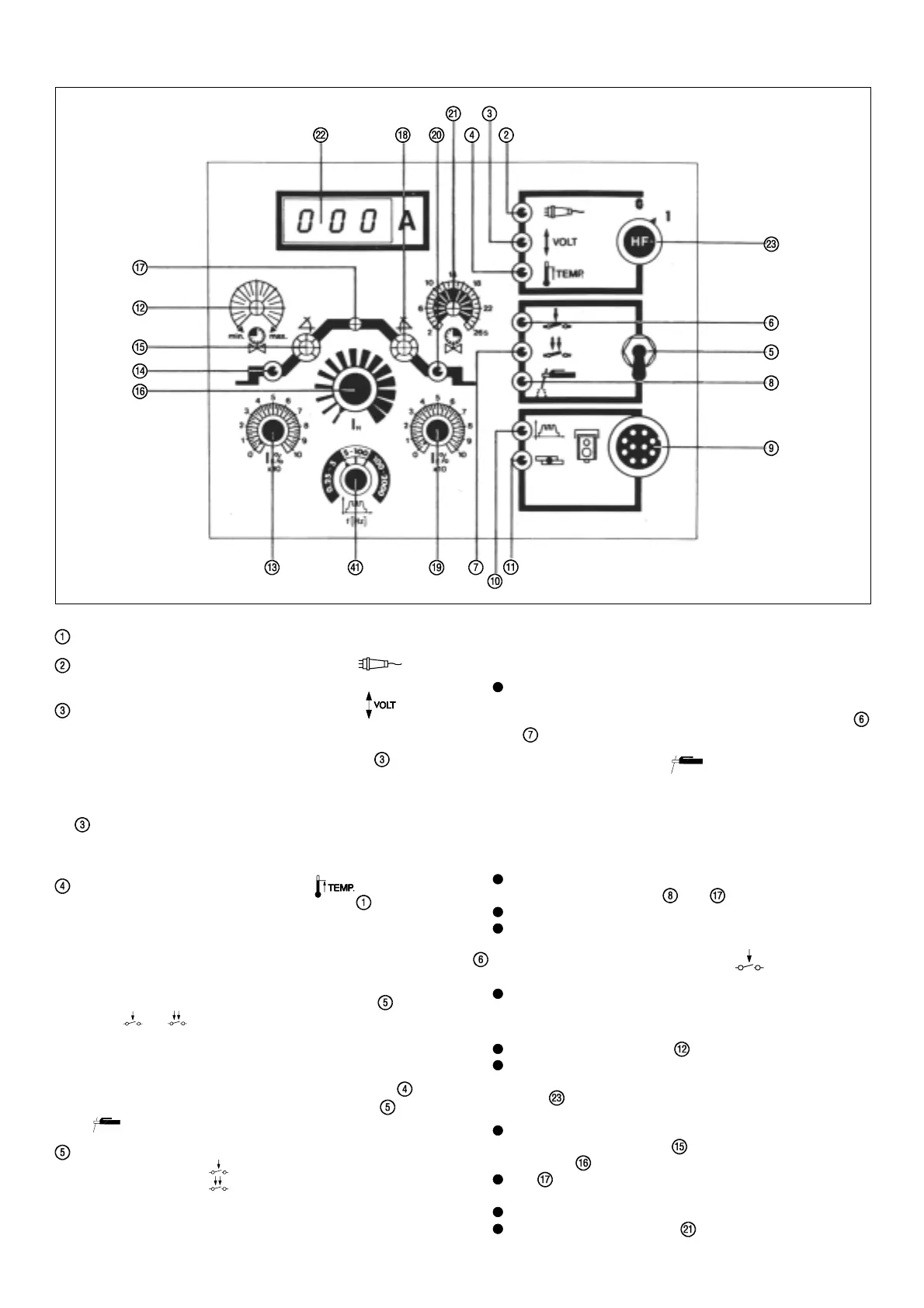

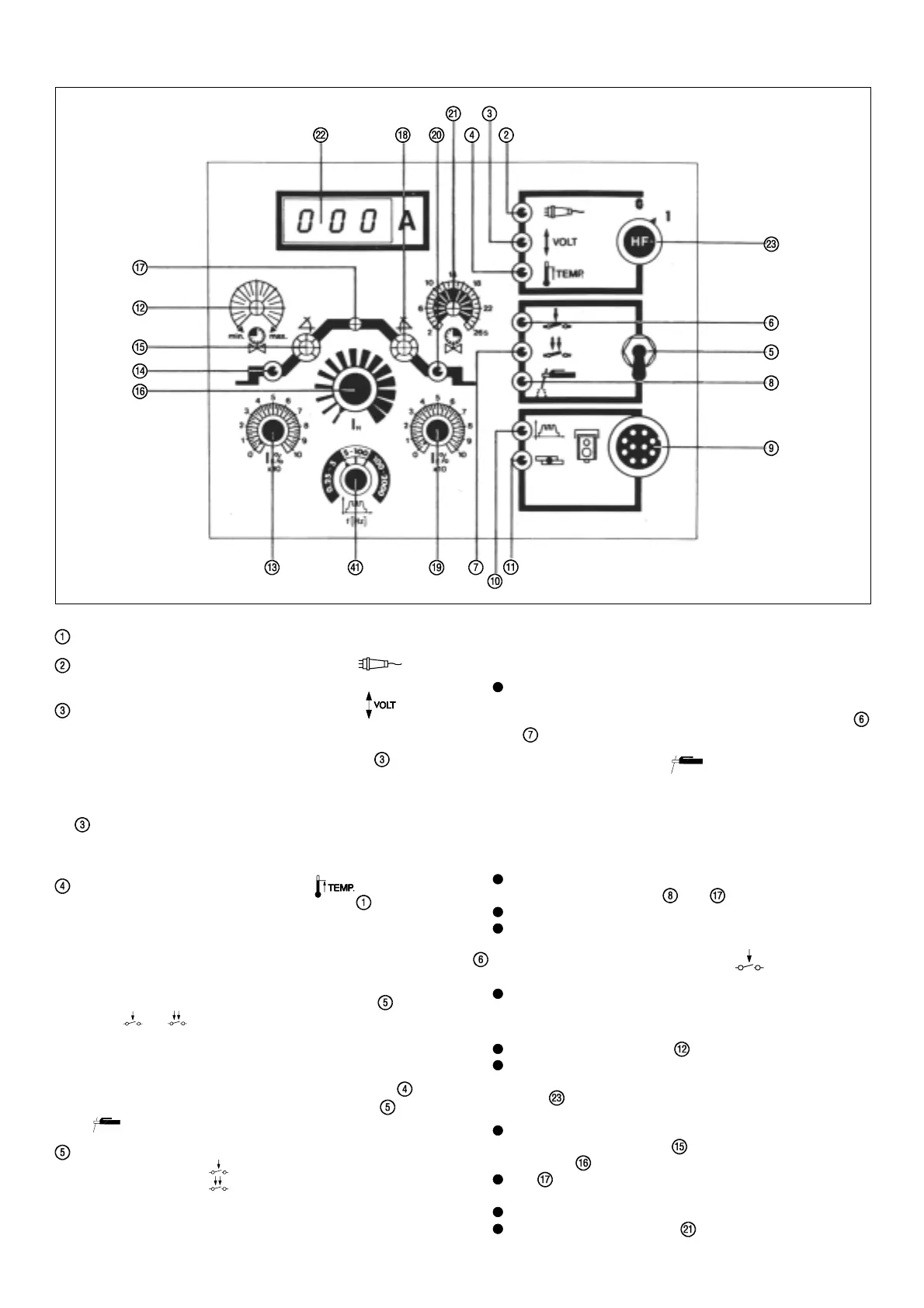

DESCRIPTION OF CONTROLS (valid for Transtig 330 and 450)

Mains ON/OFF switch (Fig. 19)

OPERATIONAL READINESS INDICATOR

lights up when the mains switch is shifted to "1"

OVER AND UNDERVOLTAGE INDICATOR

If the mains voltage rises/falls outside the +/-10% tolerance

range (Fig. 6), the voltage monitoring feature automatically

switches the machine off and the LED indicator

lights up

and stays on. In the event of momentary system voltage dips

or over-shoots, the power source will briefly cut out and then

immediately switch on again. In this case, the LED indicator

lights up for a period of 10 seconds.

If the mains voltage is within the given tolerance range, the

over and undervoltage indicator ought not to light up.

OVERTEMPERATURE INDICATOR

This lights up when the mains master switch is ON and:

a) the machine is overloaded and/or a temperature of 82° C

has been reached on one the primary or secondary heat

dissipators (see Fig. 2); or:

b) on water-cooled machines, where the power-plug for the

cooling unit is not plugged in to the 5-pole FK7 socket at the

rear of the machine. Function selector switch

is set to

TIG

or .

c) the cooling-unit plug FK7 is plugged into the back of a water-

cooled machine, but the cooling unit itself is faulty

(see Troubleshooting Guide p. 53 pt. 4).

IMPORTANT: The overtemperature indicator

goes

out as soon as the function selector switch

is set to

, even if Pts. b) and c) above apply.

FUNCTION SELECTOR SWITCH for

a) 2-step operation

} = TIG-welding

b) 4-step operation

If either of these two switch positions is selected, the machine

automatically switches over to the constant-current characte-

ristic necessary for TIG welding (= soft arc).

This puts the arc force control and hot-start devices out of

action (they may also no longer be influenced via the TP3 /

TP4-SP remote control unit).

When the TR 50-1, TR 51 or TR 52-1 remote-control units

are used, the system switches over to the operating mode

in question automatically - the respective LED indicators

or light up.

c) Manual electrode welding

When this switch position is selected, the welding characteri-

stics are governed by the mean values for ARC FORCE and

HOT-START which are fixed in the machine itself. It is only

possible to influence these parameters from outside via the

TP3 / TP4-SP remote control unit.(See description of TP3 /

TP4-SP remote control unit on p. 42-44)

After the required operating mode has been selected, the

respective LED indicator

and will light up.

FK7 cooling unit switches off automatically

Up / downslope function is inoperative

LED indicator for 2-step operation

called up via TIG torch trigger

used mainly for tack welding

Functional sequence:

1.Pull back the torch trigger and hold it down

Gas pre-flow time elapses

The arc ignites at start-arc current value I

s

either with or

without HF, depending on the position of the HF selector

switch

(N.B. HF switches off automatically following arc

ignition).

After the ignition process, the welding current rises via the

preselected up-slope (dial ) to the welding current I

H

set

on the dial

.

LED lights up.

2.Release torch trigger

Arc goes out (with or without current drop)

Gas post-flow time elapses

Fig. 15

Loading...

Loading...