34

COMMISSIONING - GENERAL DETAILS

WARNING:

EXTERNAL INTERFERENCE CAUSED BY TIG WELDING

USING HIGH FREQUENCY (HF)

The high frequency used for contact-free ignition with DC TIG

welding, can interfere with the operation of insufficiently shielded

computer equipment, EDP centres, industrial robots, computer-

controlled processing equipment and measuring stations, even

causing complete system breakdown. Also, TIG welding in resi-

dential areas may interfere with electronic telephone notworks

and with radio and TV reception.

ELECTRICAL WORK, CHANGING THE FUSES ON THE AUXI-

LIARY TRANSFORMER, OR FITTING/CHANGING THE PO-

WER PLUG, MAY ONLY BE CARRIED OUT BY A QUALIFIED

ELECTRICIAN!

The Transtig 330/450 may be operated as standard on a

mains voltage of 3x380V / 400V or 415V, provided that the

auxiliary transformer has been connected correctly for the

operating voltage in question (Fig. 5). Yellow-green lead =

protective earth conductor (PE). The other conductors, L

1

, L

2

and

L

3

, are connected to three phases of the mains plug. The phase

sequence is not important. Since the introduction of EuroNorm

IEC 38 in May 1987, mains voltage has been defined as 400V

throughout Europe.

The machine is connected in our works for 400V! This means

that it may also be run on the 3x380V mains (Fig. 6), thanks to its

tolerance range of +/- 10. Machines connected for voltages other

than 3x400V are labelled with a sticker reading: "WARNING!

MACHINE IS CONNECTED AT ...........V!"

Where the mains voltage is 3x220V, 3x440V or 3x500V, it must

first be fed through a FRONIUS ancillary autotransformer. This

may be retrofitted at any time, and can be fitted between the

trolley and the power source.

SETTING-UP INSTRUCTIONS

Open-air operation

As indicated by its protection category, the machine may be set

up and operated in the open air. However, the built-in electrical

parts must be protected from direct wetting caused by e. g.

external wet cleaning etc.

Cooling air

The machine must be set up in such a way that the cooling air

can enter and leave the machine freely through the louver-type

slots at the front and rear of the machine respectively.

Dust

Make sure that any metal dust caused by e. g. grinding work is

not sucked into the machine by the cooling fan.

Ambient temperature

The power source must be positioned well away from such

sources of heat as radiators, heating or annealing furnaces,

direct hot sunshine etc., which would raise its temperature still

further. The technical data given here in are for a max. ambient

temperature of +40°C.

WHEN HOISTING THE CRANE, MAKE SURE:

- that the chains and cables are attached to all the hoisting

points and are as near vertical as possible.

to prevent accidents, take the gas cylinder off the machine

before hoisting it.

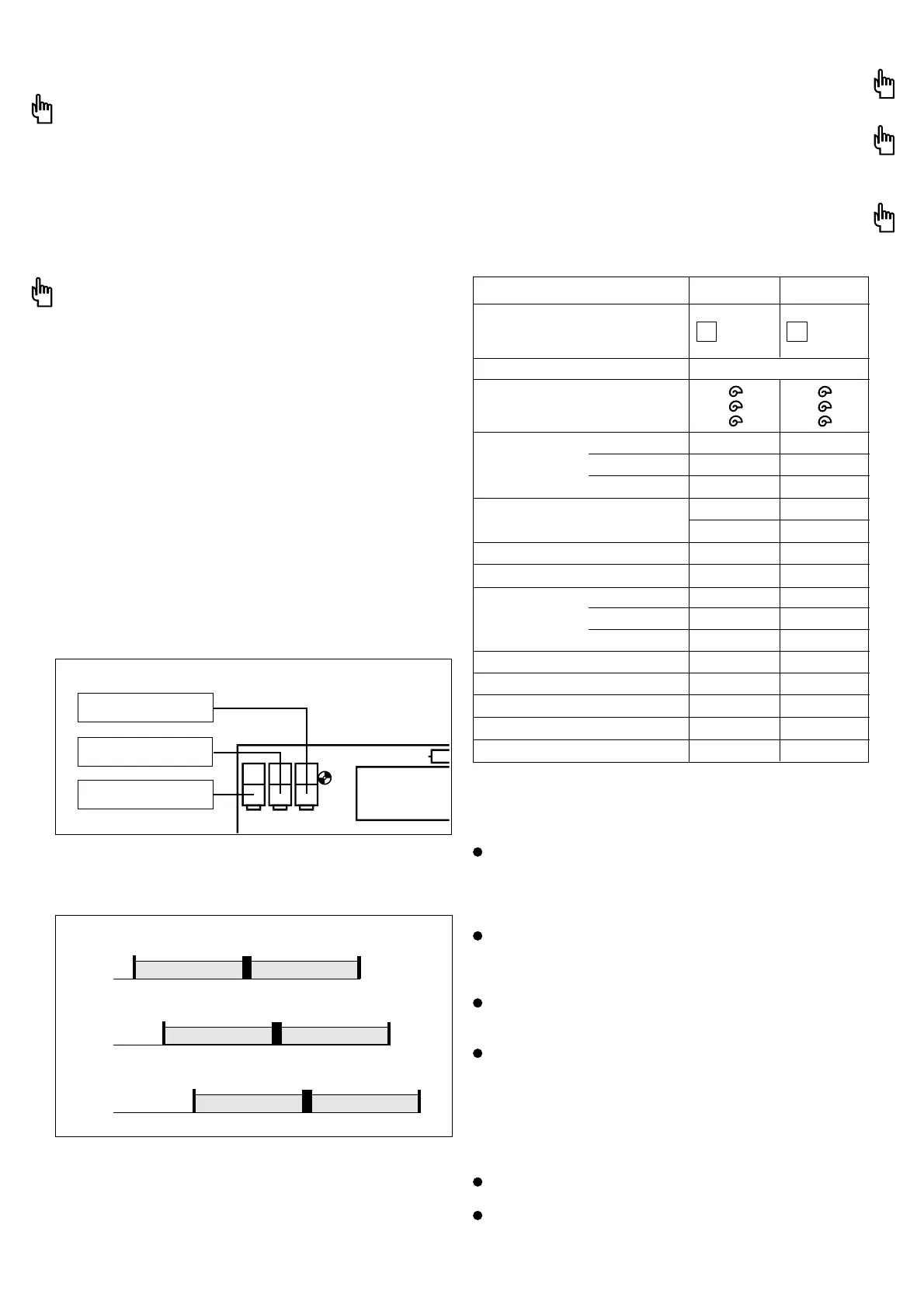

Fig. 5 3x380V / 400V / 415V mains reconnection on the VE 34. auxiliary transformer

board

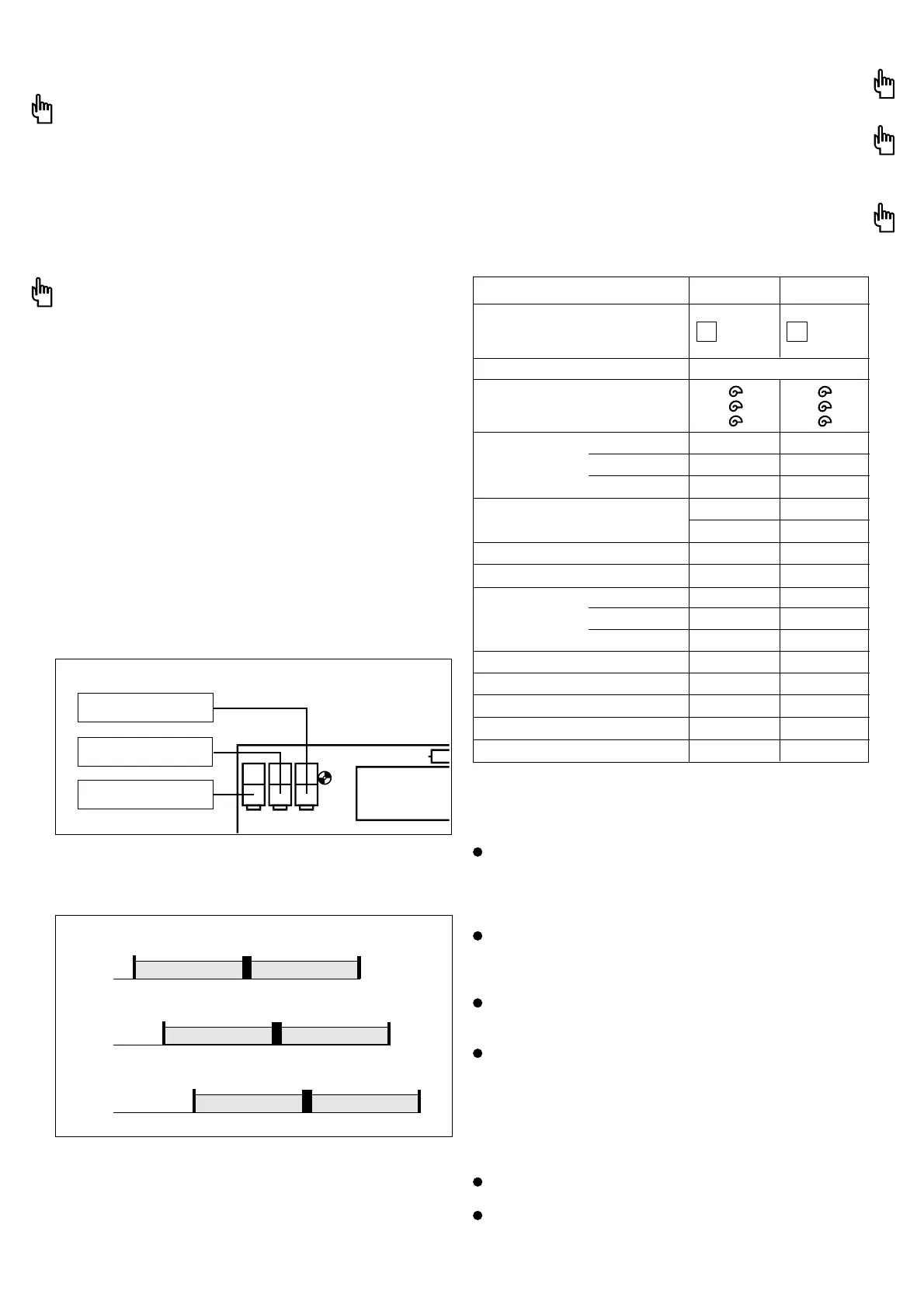

Fig. 6 Tolerance ranges of the mains voltages 3x380V / 400V / 415V

TECHNICAL DATA

Machine suitable for welding in

confined spaces under conditions of

increased electrical danger

TT 330 TT 450

Mains fuse

25 A

20 A

20 A

380 V

400 V

415 V

32 A

32 A

25 A

Welding current range

Efficiency

3 - 330 A

8,5 kVA

12,3 kVA

0,98 (150 A)

0,99 (330 A)

88 % (330 A)

100% duty cycle

3 - 450 A

17,2 kVA

22,3 kVA

0,98 (150 A)

0,99 (450 A)

90 % (450 A)

13,9 kVA

50% duty cycle

Open-circuit voltage

Operating voltage

Insulation category

Type of cooling

50 V

0 - 55 V

F

AF

300 A

Electrode/TIG

U

p

=400V

60% duty cycle

F

AF

450 A

50 V

0 - 65 V

330 A

50% duty cycle

60% duty cycle

Welding current at

Mains voltage +/-10% (switchable)

3x380V/400V/415V 50-60Hz

S S

100% duty cycle 210 A 360 A

IP 23IP 23Protection class

Cos phi

1

X6 plug connection for

mains reconnection 400V~

X5 plug connection for

mains reconnection 415V~

X7 plug connection for

mains reconnection 380V~

418V342V

380V

380V

+10%-10%

400V

440V360V 400V

+10%-10%

415V

456V373V 415V

+10%-10%

Apparent

power at

ON MACHINES DESIGNED FOR USE WITH A SPECIAL VOL-

TAGE, THE TECHNICAL DATA ON THE MACHINE RATING

PLATE WILL APPLY.

THE MAINS PLUG USED MUST CORRESPOND EXACTLY TO

THE MAINS VOLTAGE AND CURRENT RATING OF THE

WELDING MACHINE IN QUESTION, AS GIVEN IN THE TECH-

NICAL DATA!

THE FUSE PROTECTION FOR THE MAINS LEAD SHOULD BE

SUITABLE FOR THE CURRENT CONSUMPTION OF THE

WELDING MACHINE!

Loading...

Loading...