50

Fig. 42 Example of a Soft Start ignition phase in 4-step operation, with higher

start-arc current I

S

than ignition current (Tungsten electrode: 1.6 diam)

Pull back torch trigger and hold down

Release torch trigger

Gas pre-flow time

Start of cycle

Tungsten electrode

touches workpiece

Short circuit phase

Tungsten electrode

is lifted off workpiece

1,6 ø

Current rises

via ignition current

(as set on dial to the

pre-set start-arc current I

S

tilt the torch backwards until the edge of the gas nozzle is

resting on the workpiece, leaving a gap of between 2 and 3 mm

between the tip of the electrode and the workpiece. (Fig. 39a)

Close your visor.

Switch on the welding current with the torch trigger - shielding

gas starts flowing

Resting the torch on the edge of the nozzle, gradually tilt it

upwards until the tip of the electrode touches the workpiece

(see Fig. 39 b)

The arc ignites when the torch is raised and moved into the

normal position (Fig. 39 c)

Start welding

AUTOMATIC SWITCH-OFF FOR COOLING UNIT

In order to prevent the torch cooling system working unnecessarily

under no-load conditions, the machine has an automatic cooling-

unit switch-off feature.

The FK7 cooling unit is automatically switched off approx. 2 mins.

after any of the following:

MANUAL ELECTRODE WELDING

START UP

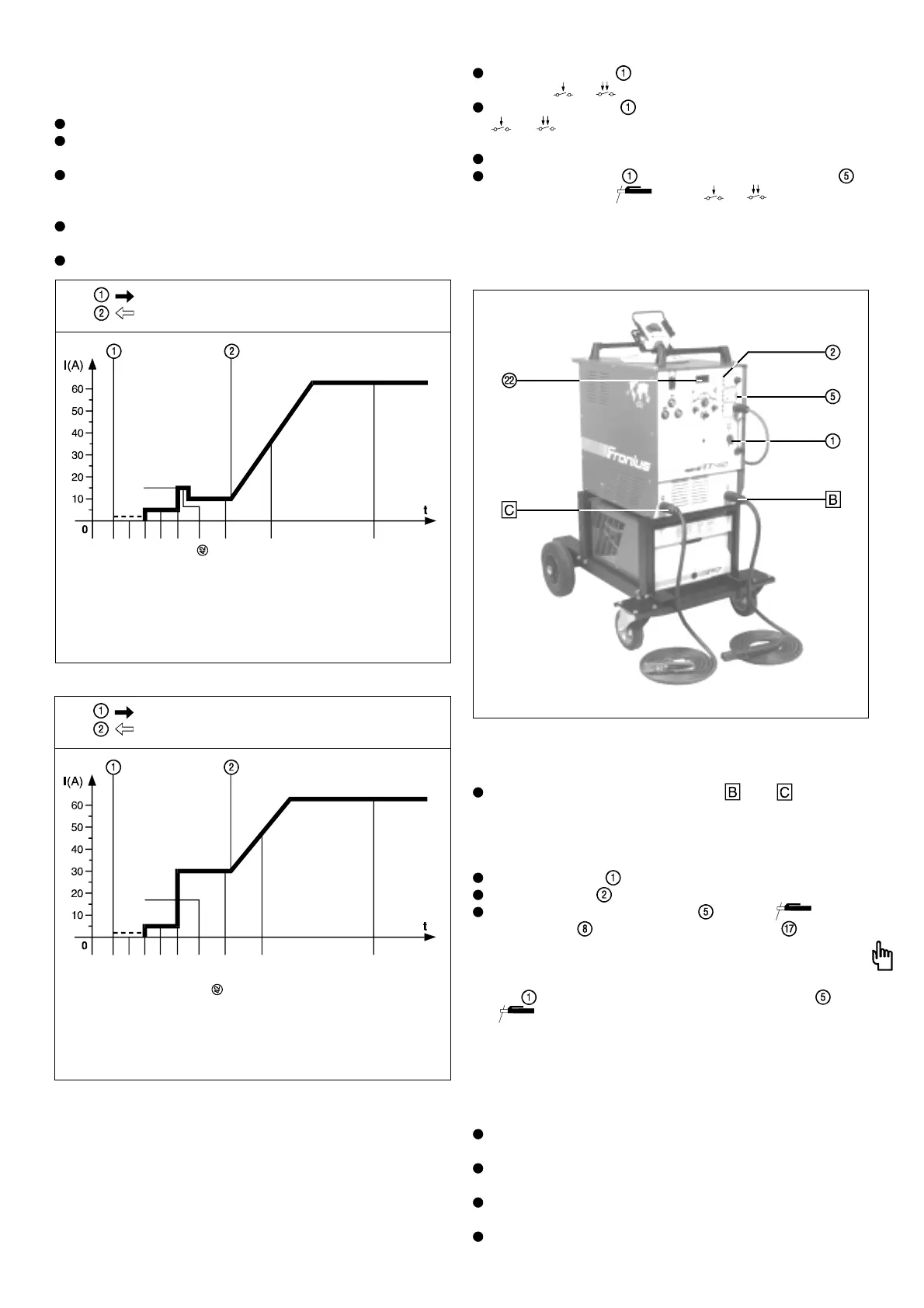

Fig. 41 Example of a Soft Start ignition phase in 4-step operation, with lower

start-arc current I

S

than ignition current (Tungsten electrode: 1.6 diam)

Pull back toch trigger and hold down

Release torch trigger

1,6 ø

Gas pre-flow time

Start of cycle

Tungsten electrode

touches workpiece

Short circuit phase

Tungsten electrode

is lifted off workpiece

Pre-set start-arc current

(dial

)

Pre-set start-arc current I

S

Current rises via up-slope

Pre-set main current I

H

Pre-set main current I

H

Current rises via up-slope

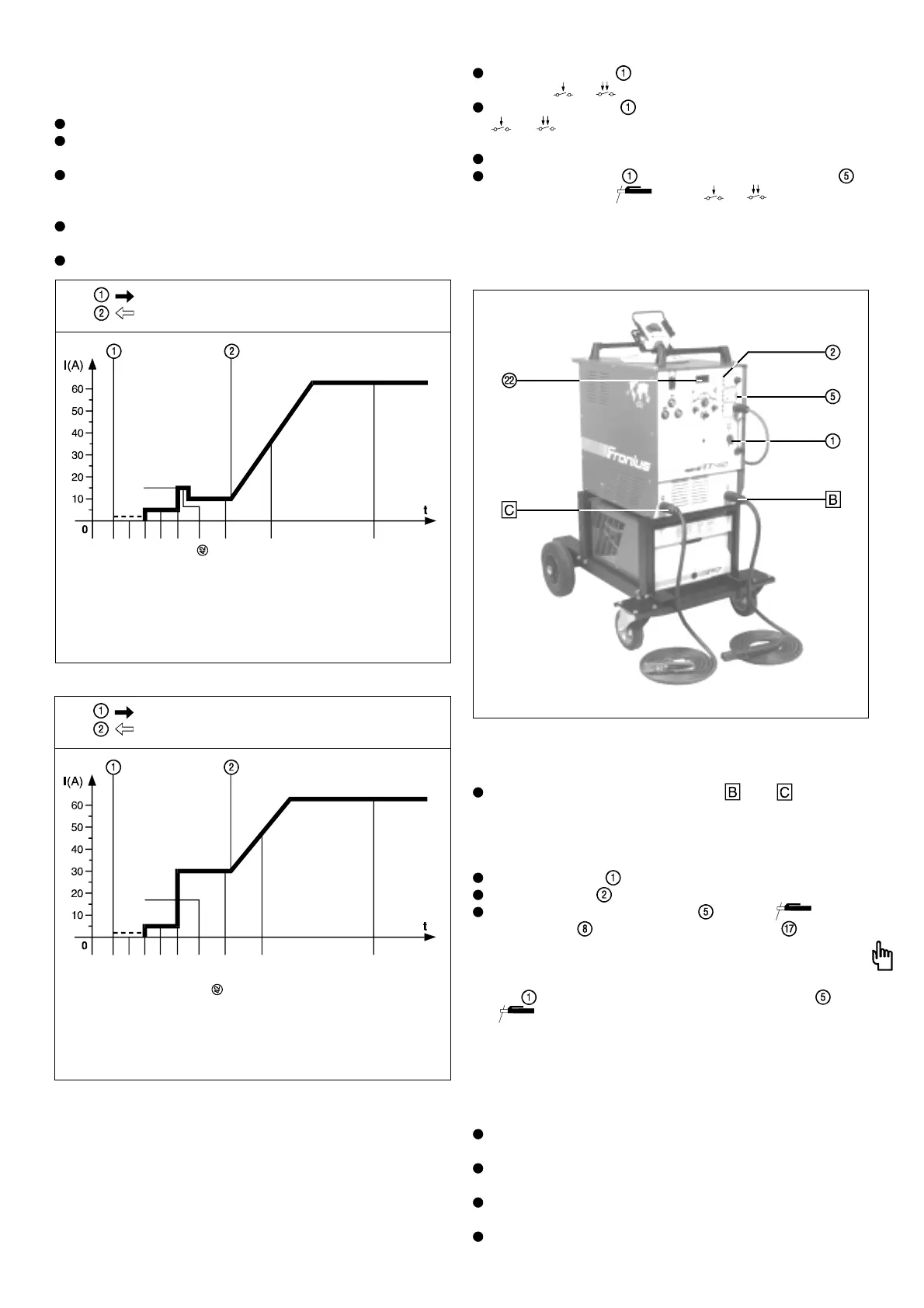

Fig. 43 Transtig water-cooled as a manual electrode welding machine,

consisting of power source with control unit, FK7 cooling unit, manual torch

with TP3 / TP4-SP (option) and welding cables.

Mains master switch is switched on, function selector switch

is on TIG

or , no welding is in progress.

Mains master switch is ON, function selector switch is in

or position, TIG torch switching sequence is tested

through in open circuit.

Completion of a TIG welding operation

Mains master switch is ON, function selector switch is

switched over from

to TIG or .

Setting up

Plug the welding cables into sockets and (which way

round will depend on the type of electrode used - observe the

electrode manufacturer's instructions) and secure by turning in

a clockwise direction. (Cable cross-section: 50 - 70mm

2

)

The TIG torch does not need to be dismounted.

Shift mains switch to "1"

The control lamp indicates that the machine is operational.

Shift the function selector switch into the position.

LED indicator

and welding current indicator light up.

WARNING! When the TRANSTIG is being used for manual

electrode welding, the tungsten electrode on the mounted

welding torch will always be live when the mains master

switch is ON and the functional selector switch is in

the

position. Make sure, when the torch is not in use,

that it is either disconnected from the machine or else

fastened to the machine in such a way (insulated) that the

tungsten electrode cannot touch any electrically conductive

or earthed parts such as the housing, gas cylinder, work-

piece etc. (If necessary fixing the tungsten electrode approx.

10 mm back from the edge of the gas nozzle!)

Connect TP3 / TP4-SP remote control unit if required

(see description of remote control operation on p. 42)

Pre-select welding current (command value for main current I

H

is displayed on ammeter )

If using remote control unit, set arc force and Hot-Start

(see "TP3 / TP4-SP remote control unit")

Initiate the welding operation.

Loading...

Loading...