49

See p. 41 for ignition monitoring feature.

TIG WELDING WITH CONTACT IGNITION

(without HF)

START UP

Fit the mounted torch with a tungsten electrode and a gas

nozzle (see the instruction manual for the torch concerned).

Plug the earth cable into the current socket and latch in place

firmly.

Connect the gas hose from the machine to the gas pressure

regulator.

Plug in the mains plug.

Switch on the mains master switch -

- mains control lamp lights up.

Set HF-selector switch to the "0" position.

Shift the function selector switch into the 2-step or 4-step

position, as required; respective LED lights up.

Start arc = contact current; set to correct value using dial

(see p. 39, Pt. , dial position "0")

If necessary, connect a remote control unit (see description of

remote control operation on p. 42).

Select welding parameters (command value for main current I

H

is displayed on ammeter ).

Open the gas cylinder valve by turning it anticlockwise.

Pull back the torch trigger and release it (4-step operation)

Turn the setscrew on the underside of the gas pressure

regulator in a clockwise direction until the working manometer

shows the required flow-rate in litres/min.

Set the gas pre-flow and post-flow times on the power source.

Pull back and release the torch trigger once again

(= welding OFF)

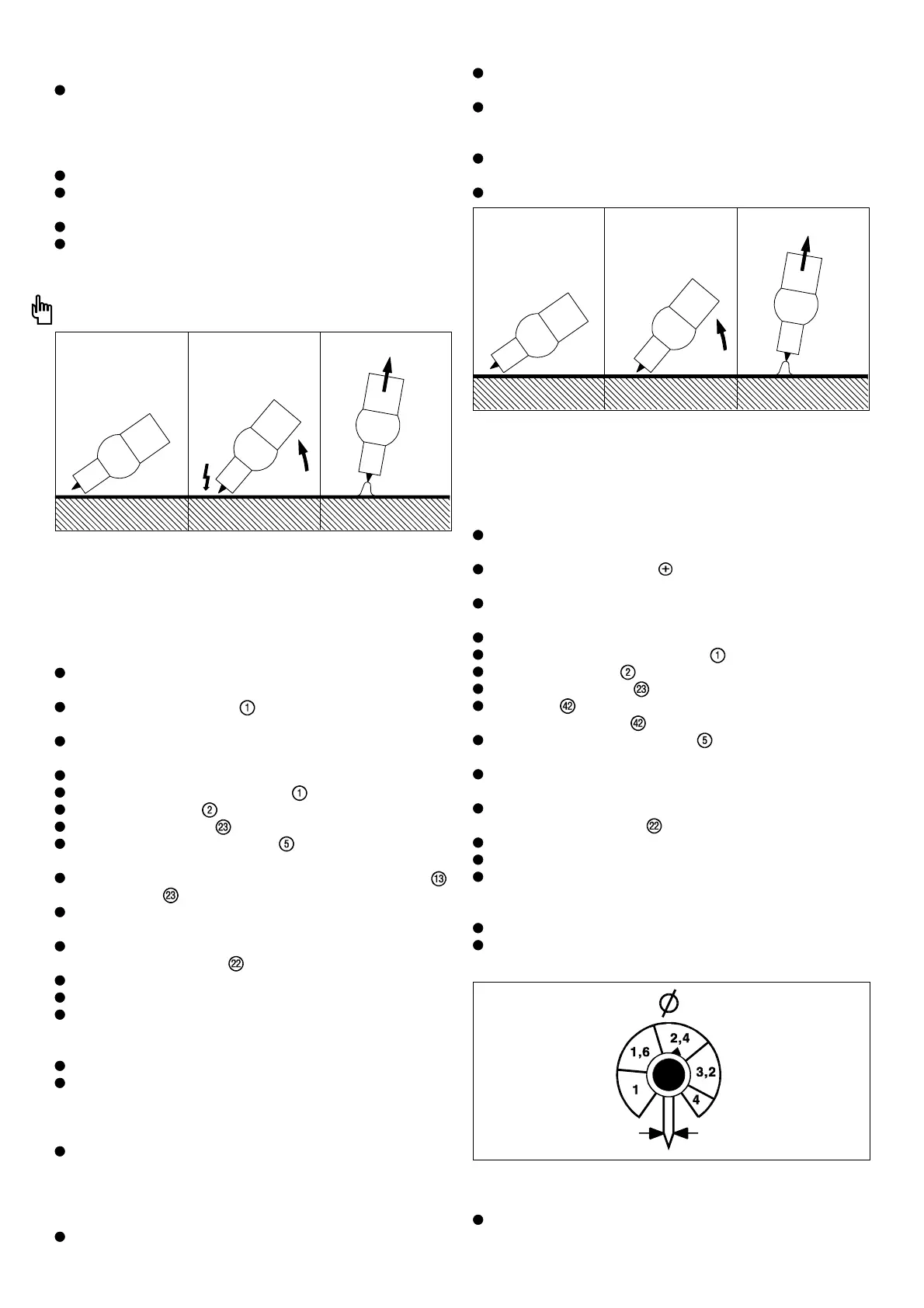

Igniting the arc:

Make sure the welding current is switched off. Place the

electrode on the weld at the point where the arc is to be ignited,

tilt the torch backwards until the edge of the gas nozzle is

resting on the workpiece, leaving a gap of between 2 and 3 mm

between the tip of the electrode and the workpiece. (Fig. 39a)

Close your visor.

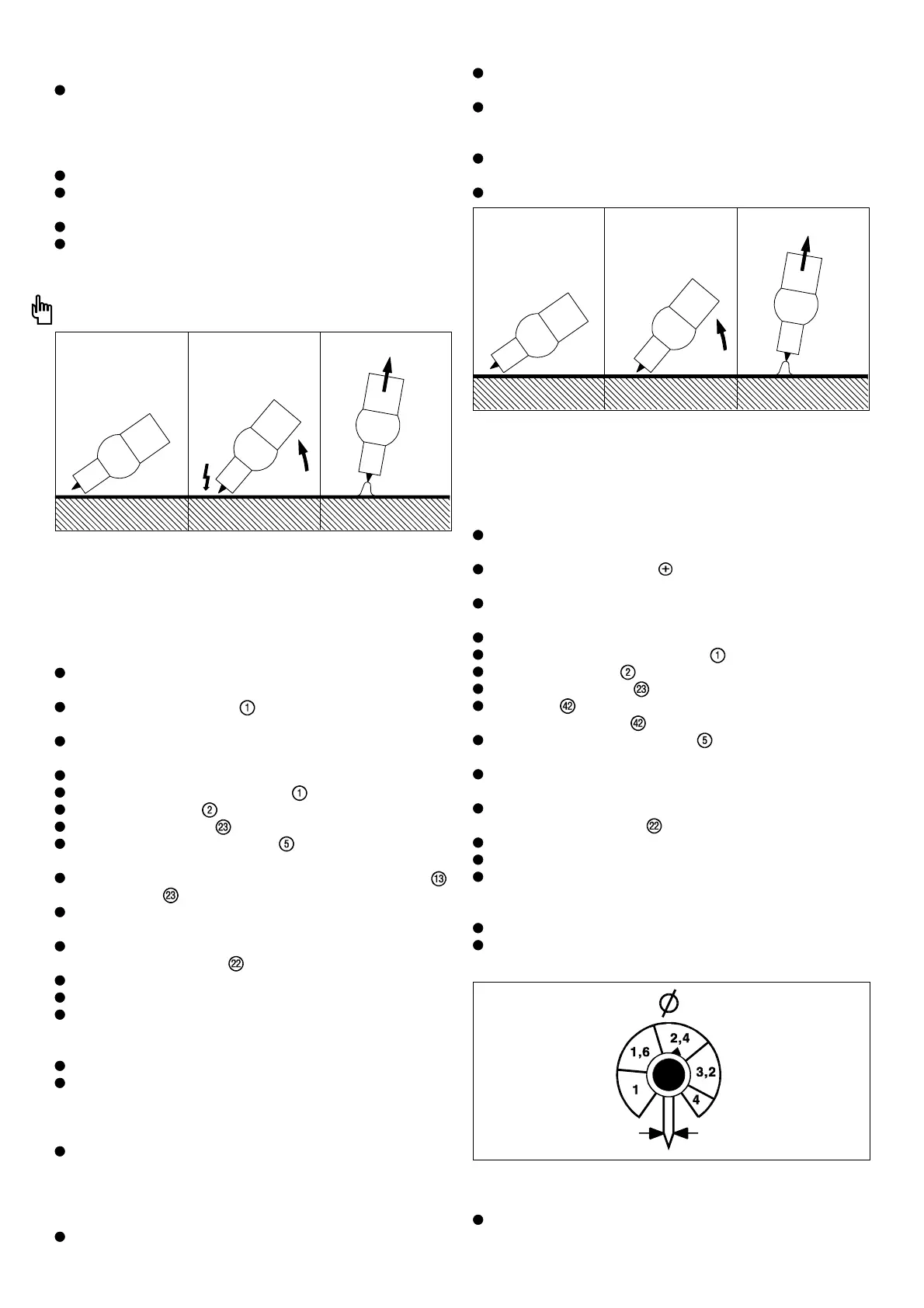

Fig. 38 Ignition with aid of ignition device

Igniting the arc: (with FHF5-1 ignition device)

Make sure the welding current is switched off. Place the

electrode on the weld at the point where the arc is to be ignited,

tilt the torch backwards until the edge of the gas nozzle is

resting on the workpiece, leaving a gap of between 2 and 3 mm

between the tip of the electrode and the workpiece. (Fig. 38a)

Close your visor

Switch on the welding current with the torch trigger - shielding

gas starts flowing

Arc ignites without touching the workpiece (Fig. 38b)

Move the torch into the normal position. (Fig. 38c)

Advantage: no contamination of either the electrode or the

workpiece.

IMPORTANT: After ignition, the high frequency switches off

automatically.

Igniting the arc:

Make sure the welding current is switched off. Place the

electrode on the weld at the point where the arc is to be ignited,

Fig. 40 Dial setting for ignition current for a 2.4mm diam. tungsten electrode

TIG WELDING WITH SOFT-START

("soft" contact ignition without HF)

START UP

Fit the mounted torch with a tungsten electrode and a gas

nozzle (see the instruction manual for the torch concerned).

Plug the earth cable into the current socket and latch in place

firmly.

Connect the gas hose from the machine to the gas pressure

regulator.

Plug in the mains plug.

Switch on the mains master switch -

- mains control lamp lights up.

Set HF-selector switch to the "0" position.

Set the dial to the diameter of tungsten electrode to be used

(Fig. 40). (See p. 39, Pt. for a description of Soft Start ignition).

Shift the function selector switch into the 2-step or 4-step

position, as required; respective LED lights up.

If necessary, connect a remote control unit (see description of

remote control operation on p. 42).

Select welding parameters (command value for main current I

H

is displayed on ammeter ).

Open the gas cylinder valve by turning it anticlockwise.

Pull back the torch trigger and release it (4-step operation)

Turn the setscrew on the underside of the gas pressure

regulator in a clockwise direction until the working manometer

shows the required flow-rate in litres/min.

Set the gas pre-flow and post-flow times on the power source.

Pull back and release the torch trigger once again

(= welding OFF)

Switch on the welding current with the torch trigger - shielding

gas starts flowing

Resting the torch on the edge of the nozzle, gradually tilt it

upwards until the tip of the electrode touches the workpiece

(see Fig. 39 b)

The arc ignites when the torch is raised and moved into the

normal position (Fig. 39 c)

Start welding

a)Fit gas nozzle b)Touch workpiece

to ignite arc

c) Arc is ignited

Fig. 39

a)Fit gas nozzle b)Contact-free

HF ignition

c) Arc is ignited

Loading...

Loading...