73

Fig. 26

Practical tips!

When the setting on the arc force control dial is adjusted upwards,

the following may be observed when rutile, basic-sheathed or

special electrodes are being used:

Easy ignition

Reduction in welding misfires

Less electrode burn-on

Good root penetration

Occasionally an increase in spattering

When welding thin sheet metal the danger of "burning through"

increases

With filling-welds, there will be a tendency for the arc to become

somewhat harder

With fine-globule electrodes (such as titanium) the above will

not be observed, as metal transfer occurs without a short

circuit being produced.

HOT-START control dial

only effective in the electrode ignition phase

Advantages:

Improved ignition even with electrodes where ignition is

normally more difficult

Improved melting of the base material in the ignition phase,

meaning far fewer cold laps

Considerable reduction of slag inclusions

est ajouter proportionnellement au courant de soudage

réglé (phase d'amorçage voir fig. 27c)

Important!

The maximum setting for the HOT-START current is automatical-

ly limited by the maximum short circuit of the machine.

Connecting the remote control unit:

Use the remote control cable to create an electrical link bet-

ween the connecting socket on the power source and the

socket on the remote control unit.

Insert the plug-in connections into the correct sockets and

screw the coupling ring on as far as possible.

Mettre le sélecteur de mode de fonctionnement idans la

bonne position suivant le mode de fonctionnement (voir

description déteillée page 67, pos.

)

When a correct connection has been made, the respective

LED or respectively and , as appropriate, will light

up on the TC 3 control unit.

Soudage sans commande à distance:

Les paramètres d'aide à l'amorçage "HOT-START" et DYNAMIQUE

sont réglés dans l'appareil sur une valeur moyenne

(voir fig. 49, page 86).

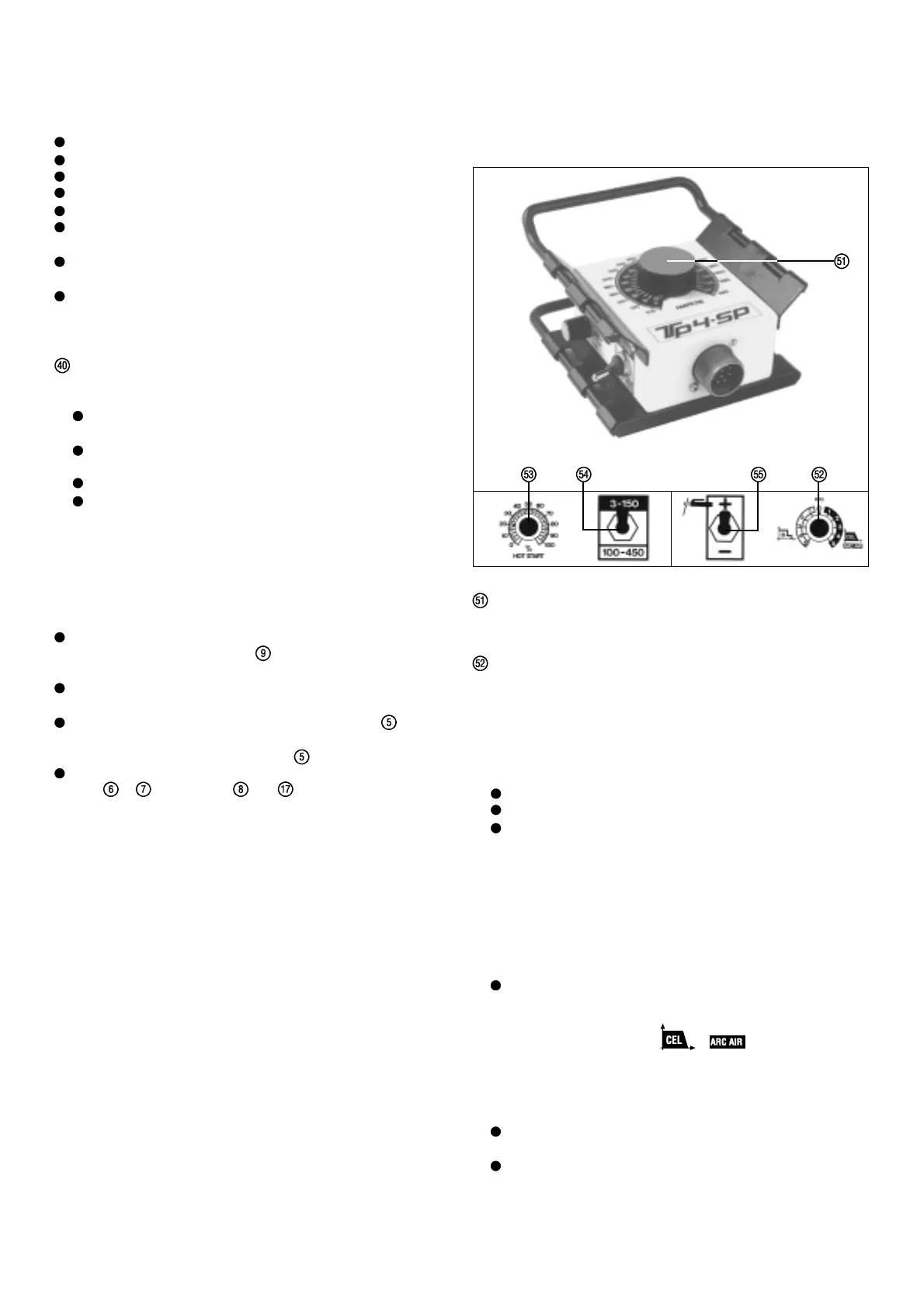

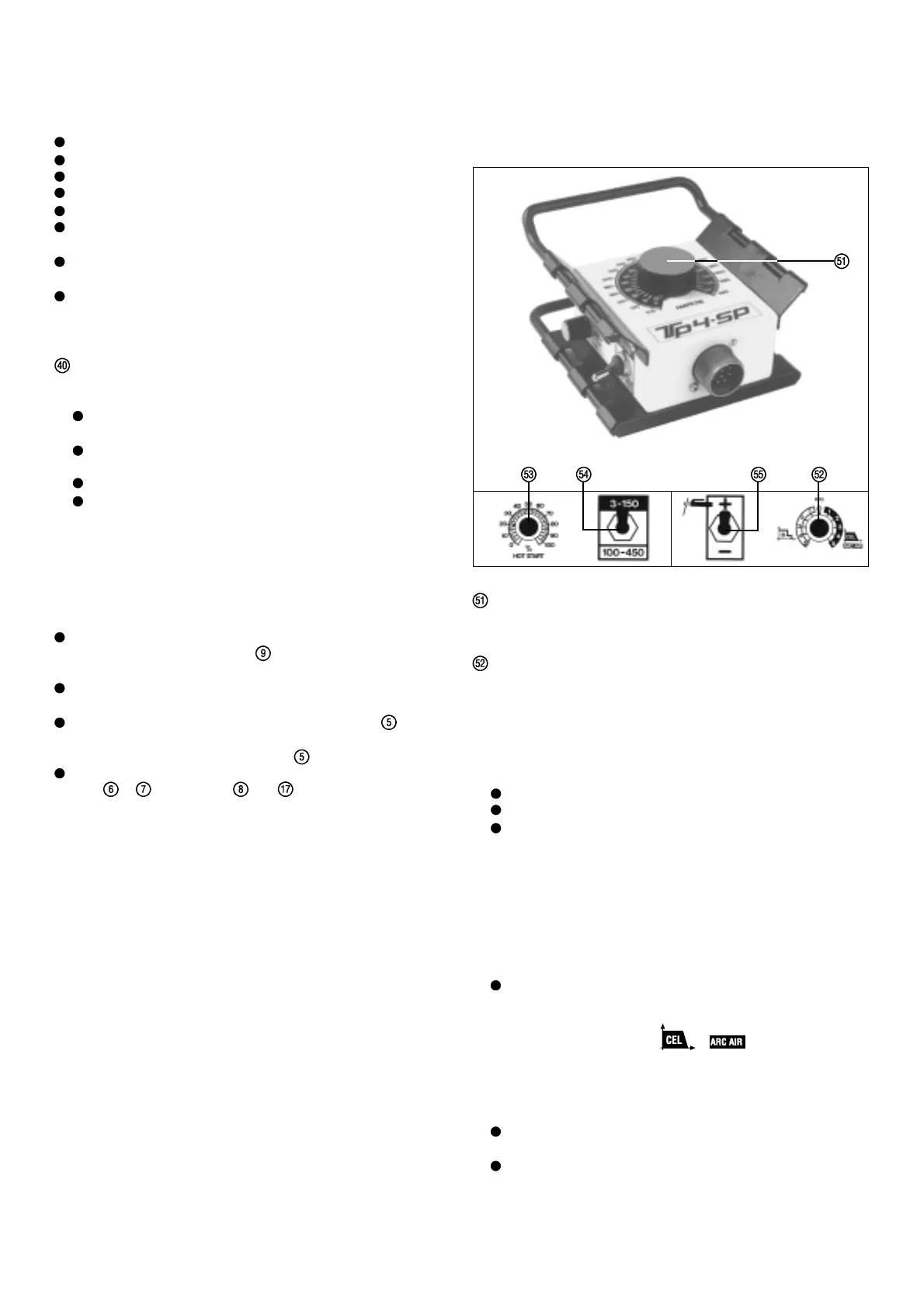

TELEREGULATEUR DE SOUDAGE MANUEL

A L'ELECTRODE ENROBEE TIG TP 4-SP

(seulement pour TT 450)

(aimant de fixation du télérégulateur sur la pièce à travailer

monté)

WELDING CURRENT DIAL

Welding current is steplessly adjustable in two ranges bet-

ween 3-150A and 100-450A.

ARC FORCE CONTROL DIAL

Influences the short circuit amperage at the moment of drop

transfer

At scale setting "0" TIG there is no increase at all in the

short circuit amperage at the moment of drop transfer

(Constant current characteristic = soft arc; Fig. 27a)

Range of application:

TIG-DC welding

Welding using rutile electrodes (fine globules)

Basic-sheathed electrodes for the medium and higher am-

perage range

CAUTION! When welded at low load, basic-sheathed elec-

trodes tend to "get stuck" on the workpiece.

At scale setting "1-5" there is a very considerable

increase in amperage at the moment of drop transfer

(Constant current characteristic with electronic arc-force

effect; 5 = hard arc; Fig. 27a)

Range of application:

With basic-sheathed electrodes (coarse globule) when

these are used for welding in the lower amperage range

(vertical-up seam, coating edges, root-welding etc.)

At scale settings of "1-5" / there is a change in

the slope of the machine output characteristic (falling charac-

teristic with electronic arc-force effect; 5=sharp, hard arc,

Fig. 27b)

Range of application scale "4-5":

All CEL-electrodes, also when these are used for welding in

the lower amperage range.

ARC-AIR-GOUGING (gouging, cutting etc.)

In the "1-3" scale range, the arc is softer. This leads to a

reduction in spatter, but also to Kb and CEL electrodes getting

"stuck" on the workpiece, especially at low amperages.

Scale range "1-3" is thus not suitable for ARC-AIR gouging

or for welding CEL electrodes.

Loading...

Loading...