74

IMPORTANT: In the

and arc-force ranges, due

to the slope of the characteristic, the welding amperage will de-

pend either on the arc-drop voltage of the electrode being used

or on the gap between the electrode and the workpiece, and thus

may not correspond exactly to the value set on the scale.

Practical tips!

When the setting on the arc force control dial is adjusted upwards,

the following may be observed when rutile, basic-sheathed, CEL

or special electrodes are being used:

Easy ignition

Reduction in welding misfires

Less electrode burn-on

Good root penetration

Harder arc

Occasionally an increase in spattering

When welding thin sheet metal the danger of "burning through"

increases

With filling-welds, there will be a tendency for the arc to become

somewhat harder

With fine-globule electrodes (such as titanium) the above will

fewer be observed, as metal transfer occurs without a short

circuit being produced.

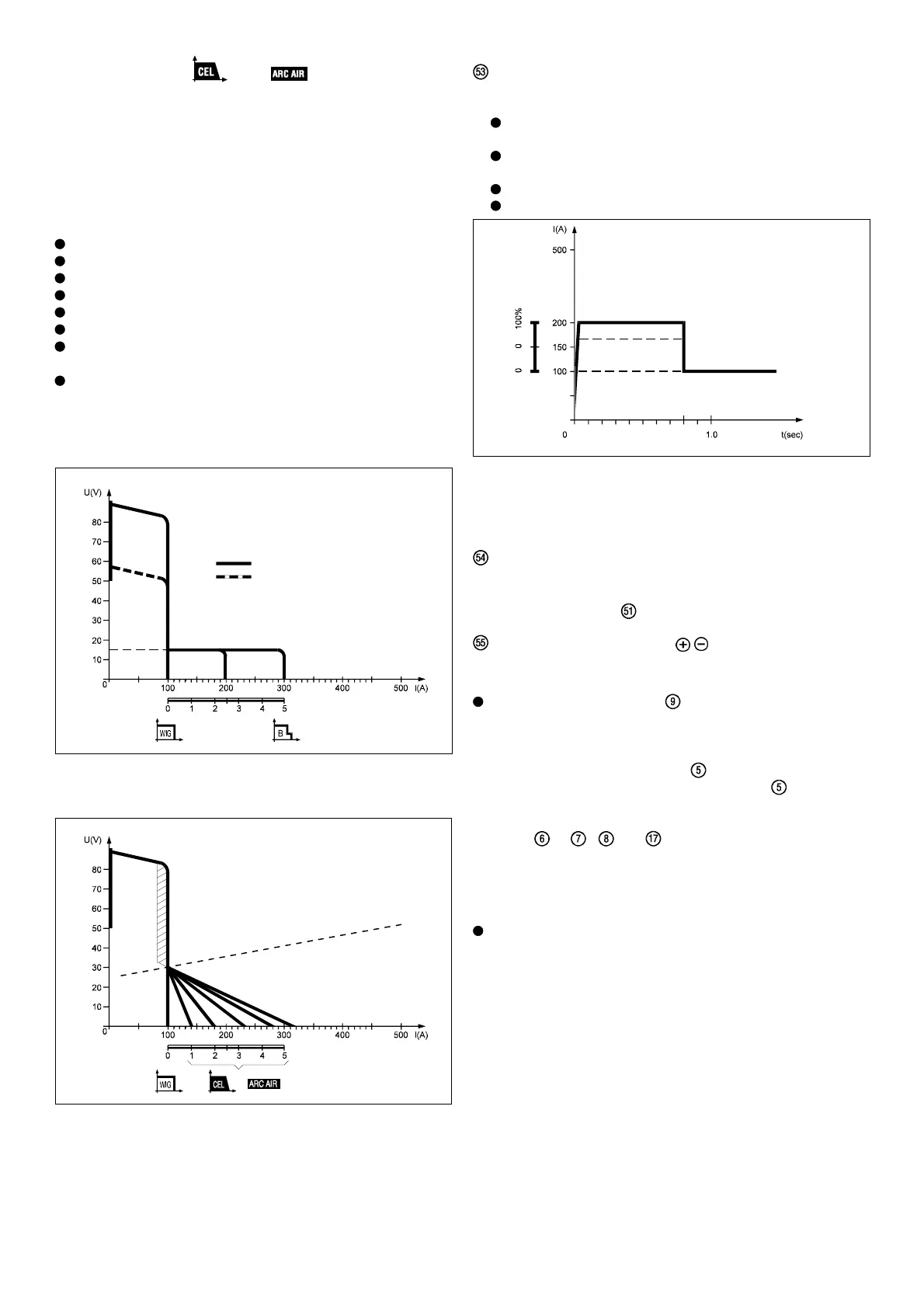

REGULATEUR D'AIDE A L'AMORÇAGE "HOTSTART"

seulement actif dans phase d'amorçage de électrode

Avantages:

amélioration des caractéristiques d'amorçage aussi avec

des électrodes d'amorçage difficile

fusion amélioré du métal de base dans la phase d'amorçage

et par conséquent nombre réduit de soudures froides

inclusion de scories largement évitée

est ajouté proportionnellement au courant de soudage réglé

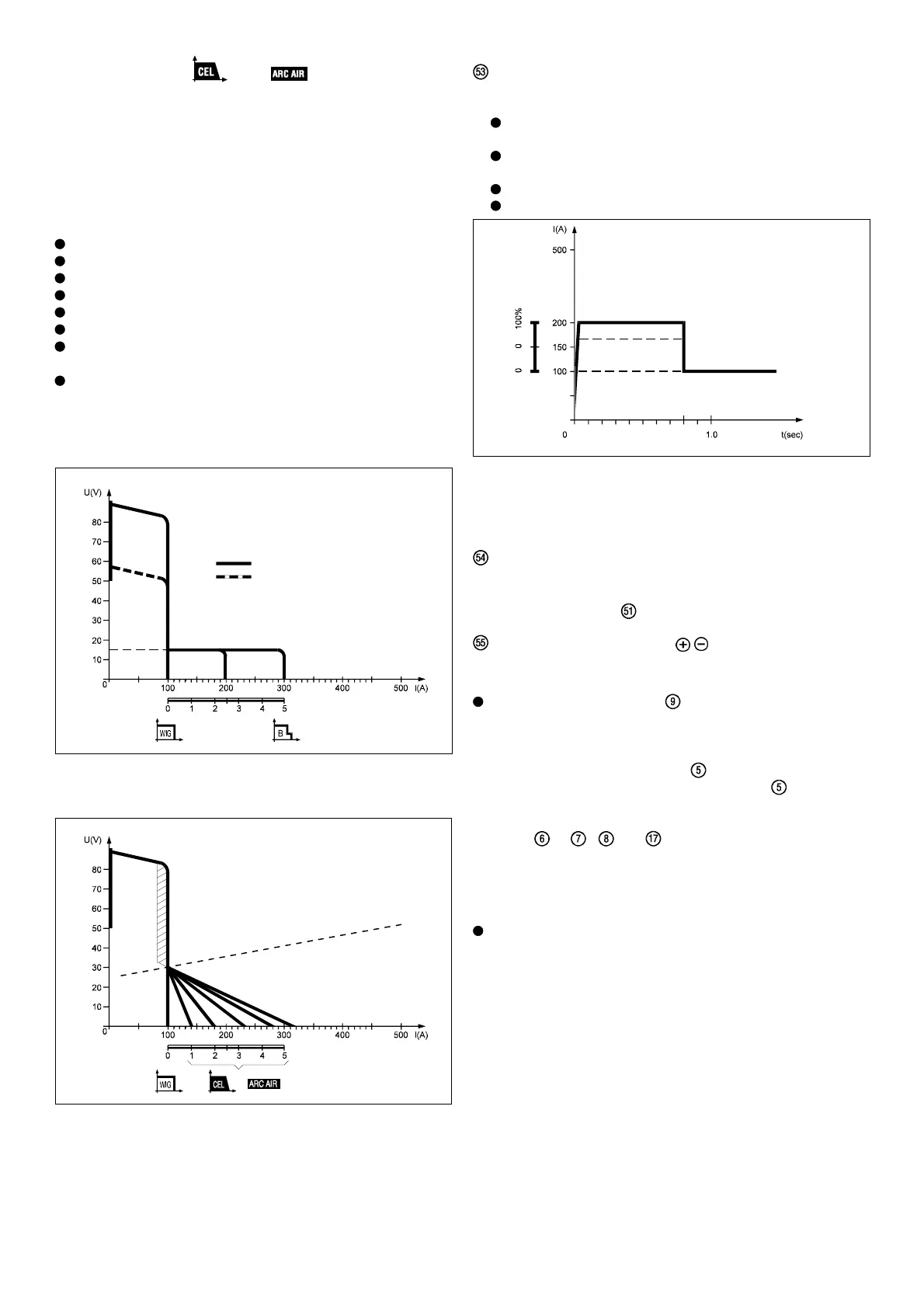

Fig. 27a Effect of arc force control dial on constant-current characteristic at the

moment of short circuiting. Welding current setting 100 A

Fig. 27b Effect of arc force control dial on falling characteristic at the moment of

short circuiting. Welding current setting 100 A

ARC CHARACTERISTIC

ARC FORCE CONTROL DIAL

DYNAMIKREGLER

TT 450

TT 330

Fig. 27c Phase d'aide à l'amorçage HOT-START courant de soudage réglé: 100 A

Aide à l'amorçage

IMPORTANT: Le courant total d'AIDE A L'AMORÇAGE "HOT-

START est limité automatiquement par le courant de court-circuit

maximum de l'installation

RANGE SWITCH

This divides the overall welding range of the machine into two

overlapping sub-ranges. The welding amperage can be set

continuously on dial

.

POLE-CHANGING SWITCH

Not in use!

Connecting up the remote-control unit:

Link the connecting-socket on the power source with the

socket on the remote control unit via the remote control cable.

Plug in the connectors the right way round, and screw the

swivel nuts down as far as they will go.

Shift the function selector switch

into the correct position for

the operating mode required. (See p. 37, Pos.

for a detailed

description).

If a correct connection has been made, the appropriate control

lamps

or / and will light up on the TC3 control

unit.

Welding without a remote control unit:

The parameters for HOT START and ARC FORCE are set to

average values in the machine (see Fig. 49 on p. 56)

Welding CEL electrodes and ARC-AIR gouging are only

possible within certain limitations.

Loading...

Loading...