57

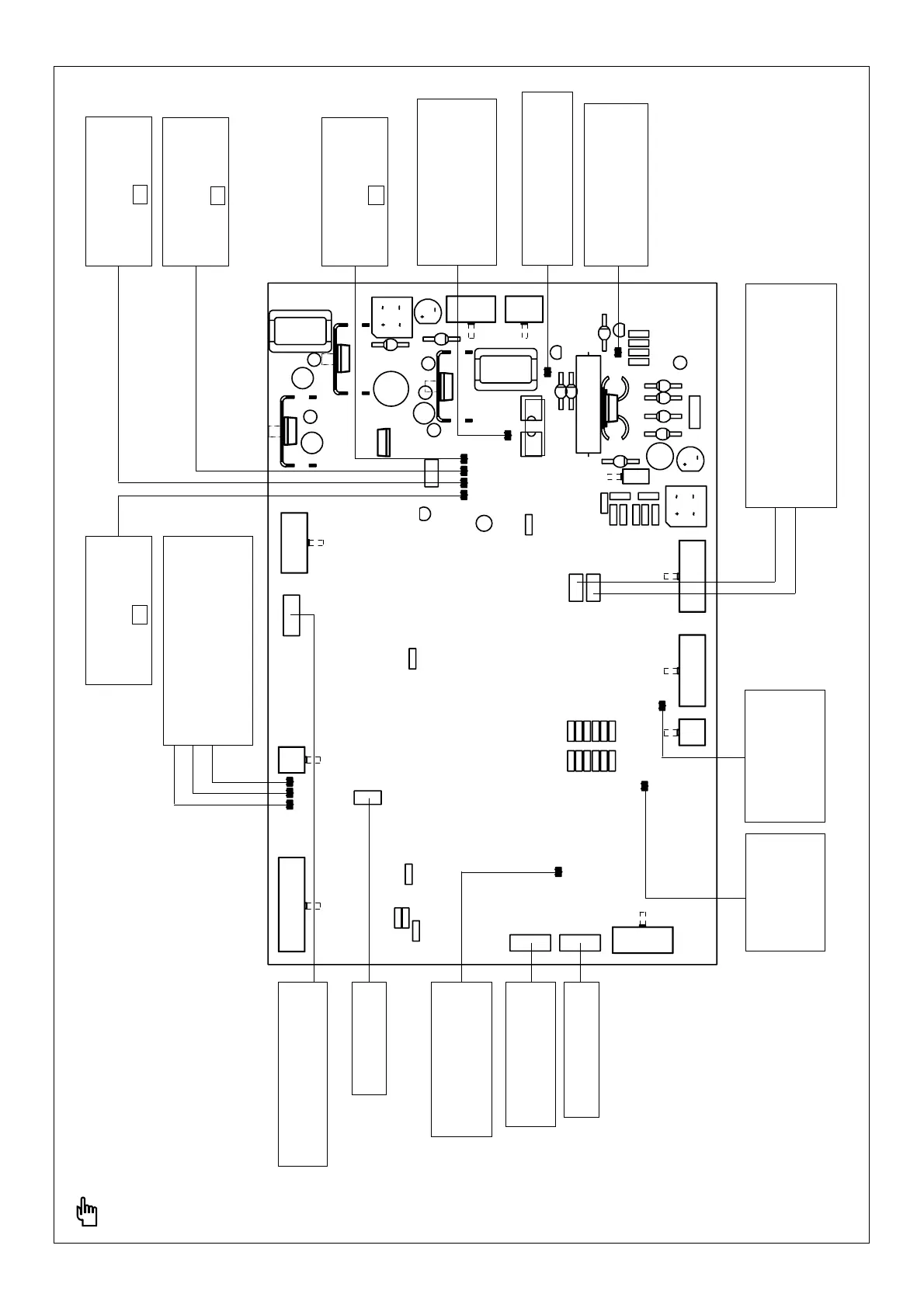

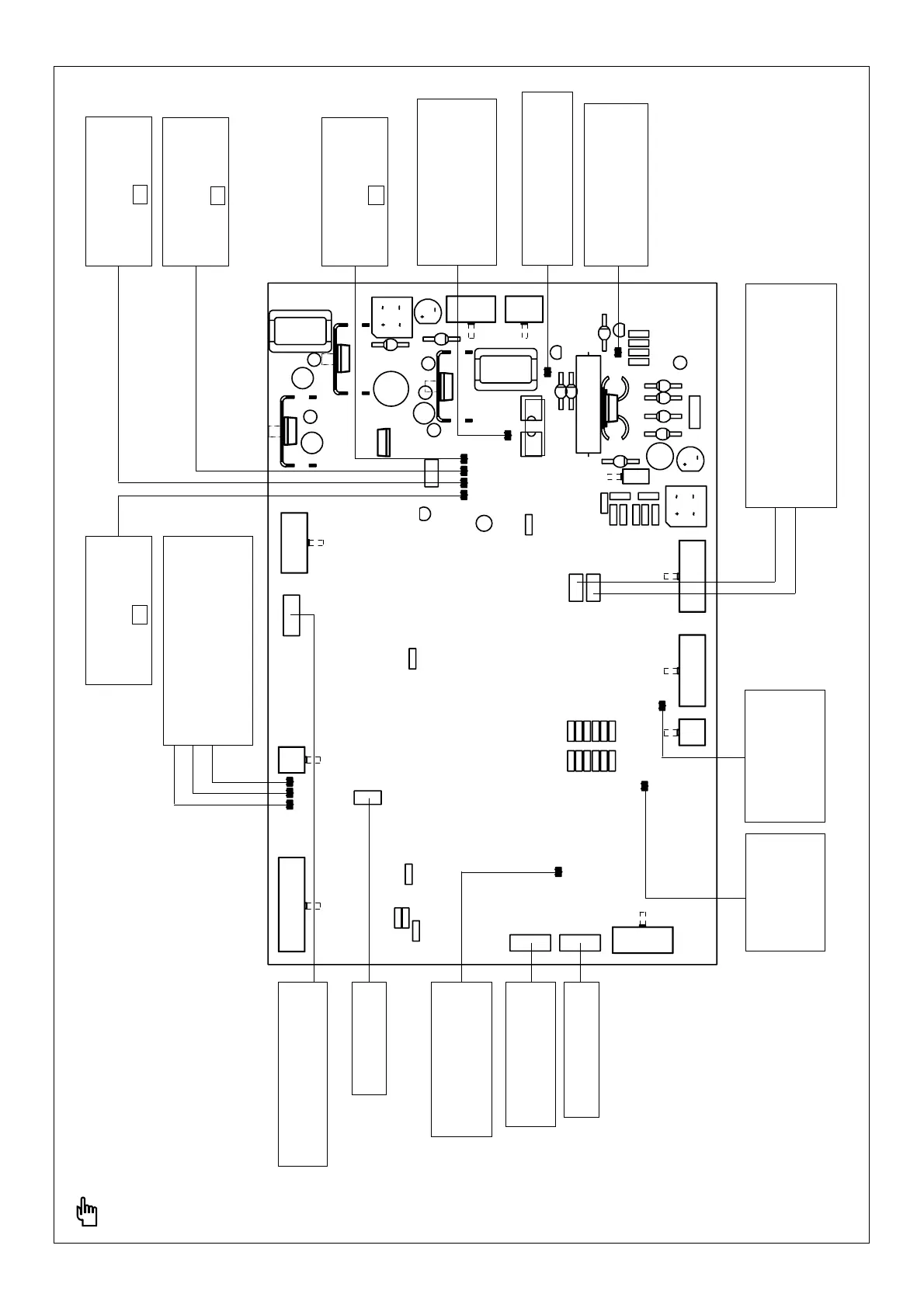

Fig. 51 LED checklist and description of setting-dials on RET 34. controller board

WARNING: Setting-dials not figuring above

may only be adjusted by Fronius personnel!

REMOTE CONTROL UNIT

LED indicator is lit up

when remote control unit

is activated

Setting dial for

HOT-START TIME

OPEN-CIRCUIT VOLTAGE -

STARTING SIGNAL

LED indicator goes out

3 secs. after current has

started to flow

LED indicator lights up when

OPEN-CIRCUIT VOLTAGE

is present

DES. VALUE FOR WELDING CURRENT

DES. VALUE FOR ARC FORCE

DES. VALUE FOR HOT-START

The higher the desired values,

the brighter the LED indicators.

Setting dial for

WELDING CURRENT Max. (300/450A)

WELDING CURRENT Min. (3A)

- is active in electrode and TIG

welding modes

CONTROLLER OUT

(Des. value for PWM).

The higher the desired

values, the brighter the

LED indicators.

LED indicator -15V

Must always be lit up when

the machine is ON -

otherwise F3 is faulty

LED indicator +5V

Must always be lit up when

the machine is ON -

otherwise F2 is faulty

LED indicator +10V

Must always be lit up when

the machine is ON -

otherwise F2 is faulty

Setting dial for

HOT-START CURRENT

(internal)

Setting dial for

ARC FORCE (internal)

PWM start-up

LED indicator lights

up as dictated by

current-flow

recognition

CURRENT FLOW SIGNAL:

LED indicator lights up when

welding current flow is

recognized

Setting-dial for striking-current,

10-30A; is only active for TIG

contact ignition without soft-start

LED indicator +15V

Must always be lit up

when the machine is ON -

otherwise F2 is faulty

Loading...

Loading...