72

Please note :

TECHNICAL DETAILS such as:

descriptions of the torch components

design of the torch hosepack

technical data

how to prepare and fit the tungsten electrode etc.

- can be found in the operating manual for the torch in question.

REMOTE CONTROL OPERATION

Remote control units are intended for use in situations where the

welding parameters must be set directly from the welding work-

place. The remote control unit is connected electrically to the

power source by means of special cables 5 or 10 m in length

(voir déscription des éléments de commande page 69, point )

The following types of remote control unit are available:

1. Manual electrode and TIG remote control unit TP3

2. Manual electrode and TIG remote control unit TP4-SP

3. TIG pulsed-arc remote control unit TR50-1

4. TIG spot-welding remote control unit TR51

5. TIG remote-control pedal unit TR52-1

TELEREGULATEUR DE SOUDAGE MANUEL

A ELECTRODE ENROBEE TIG TP3

(seulement pour TT 330)

Cette commande à distance du poste de travail est utilisée

spécialement pour le soudage manuel à l'électrode enrobée et le

soudage TIG C.C. (aimant de fixation de la commande à distance

sur la pièce à travailler est monté)

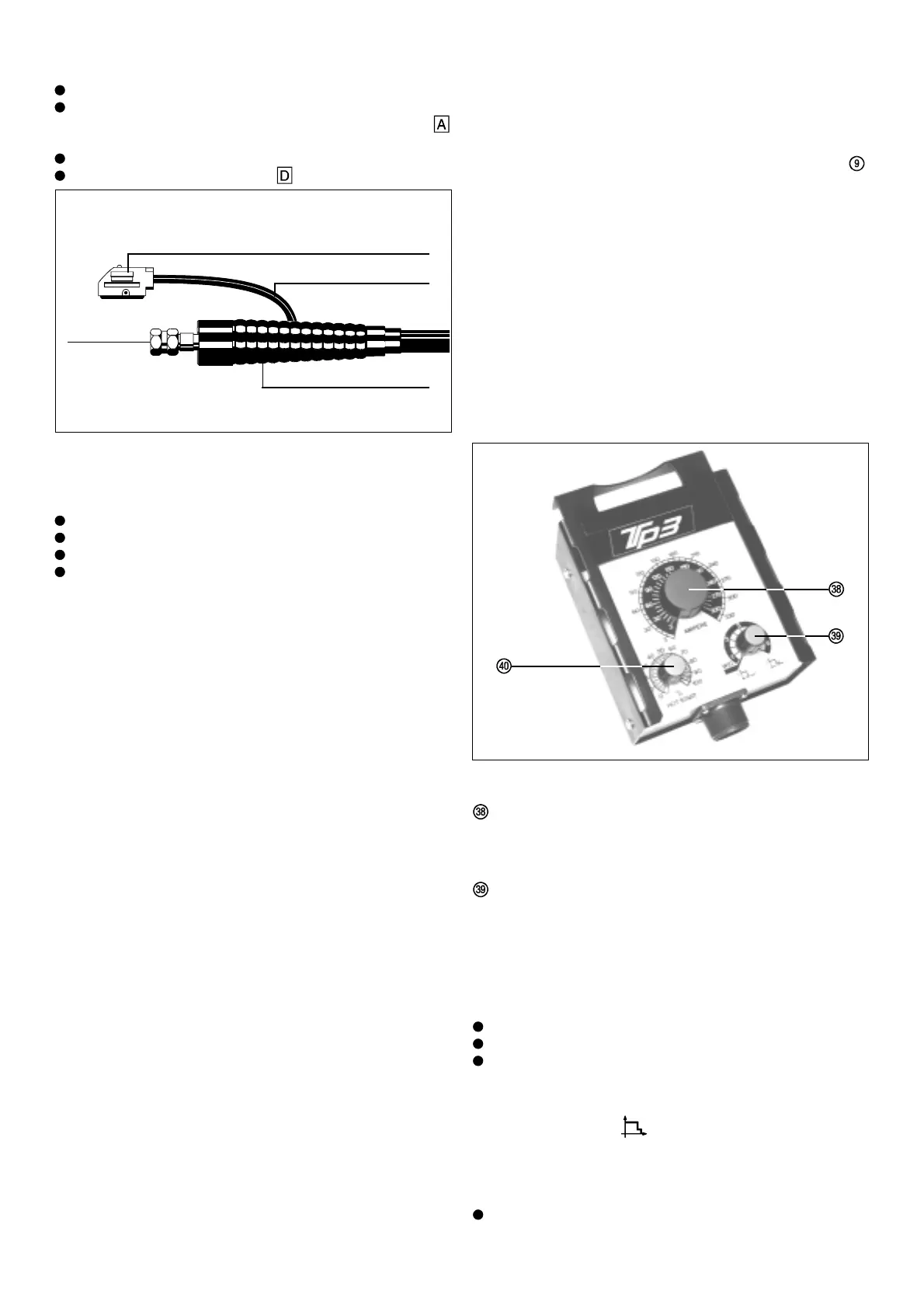

ASSEMBLING a gas-cooled TIG torch

Pull back the rubber sleeve from the rear of the torch

Screw the hexagon nut (width across = 21) of the gas+current

connection onto the torch connector point on the machine

and tighten firmly.

Push the rubber sleeve back over the hexagon nut.

Plug the control plug into socket and latch it.

Fig. 24 Torch connection gas-cooled

Hose sleeve

Control plug

Control cable

Gas and current

connection

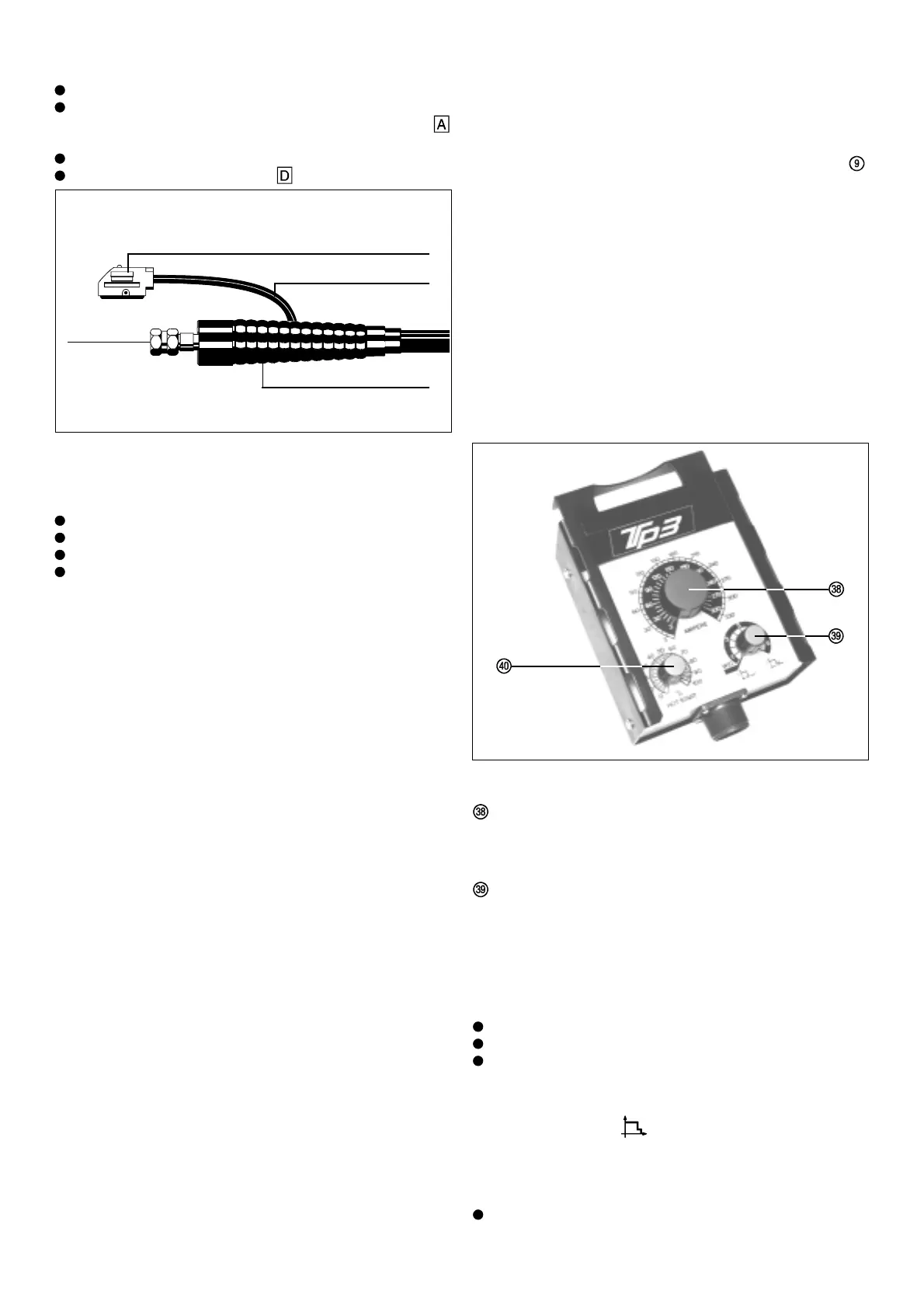

Fig. 25

REGULATEUR DU COURANT DE SOUDAGE =

courant principal I

H

Réglage continu du courant de soudage de 3 - 330A

(échelle graduée exterieur)

ARC FORCE CONTROL DIAL

Influences the short circuit amperage at the moment of drop

transfer (from electrode to workpiece)

At scale setting "0"

TIG there is no increase at all in the short

circuit amperage at the moment of drop transfer

(Constant current characteristic = soft arc; Fig. 27a)

Range of application:

TIG-DC welding

Welding using rutile electrodes (fine globules)

Basic sheathed electrodes in the medium and upper amperage

ranges

Caution! When welded at low load, basic-sheathed electrodes

tend to "GET STUCK" on the workpiece.

At scale setting "10" there is a very considerable in-

crease in amperage at the moment of drop transfer

(Constant current characteristic with electronic arc-force effect;

5 = hard arc; Fig. 27a)

Range of application:

Basic sheathed electrodes (coarse-globule), when these are

to be welded in the lower amperage range

(vertical-up seams, edge hardfacing welds, root welding etc.)

Loading...

Loading...