Operation

50940411/G0219 96 Printed in U.S.A.

Lift Arm Operation

Do not lift loads exceeding rated operating

capacity. See “Payloads/Capacities” on page 38.

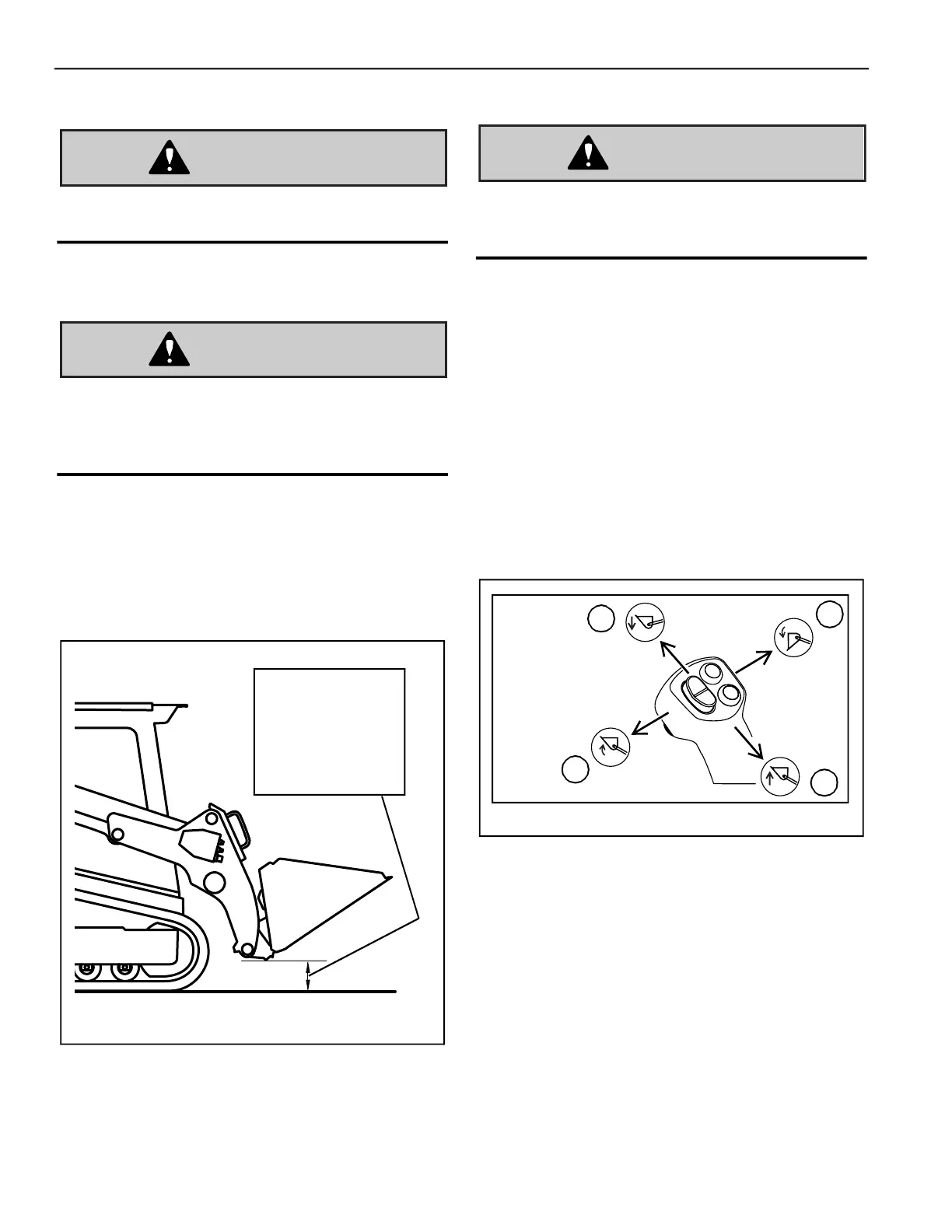

Attachment Transport Position

Always transport loads in transport position to

minimize the possibility of tipping or rollover

accidents and unstable balance conditions that

can cause loss of control.

Carry materials 200-300 mm (8-12”) above the

ground, and adjust as necessary to clear obstacles.

Generally, carry the load as low as safely possible.

Tilt buckets back, as shown in Fig. 88, to prevent

spilling material.

t

Joystick Control Patterns

Always lock-out hydraulic functions by raising

the arm rests/safety bars whenever parking the

machine.

The control joysticks control lift arm raise and

lower, attachment tilt, optional attachment quick-

hitch lock, and auxiliary hydraulics flow control.

Two different control patterns are available for lift

arm operation: ISO and D-H. See “Control

Joysticks” on page 55 for information about

switching between ISO and D-H control patterns.

NOTE:

The D-H control pattern is an optional

feature.

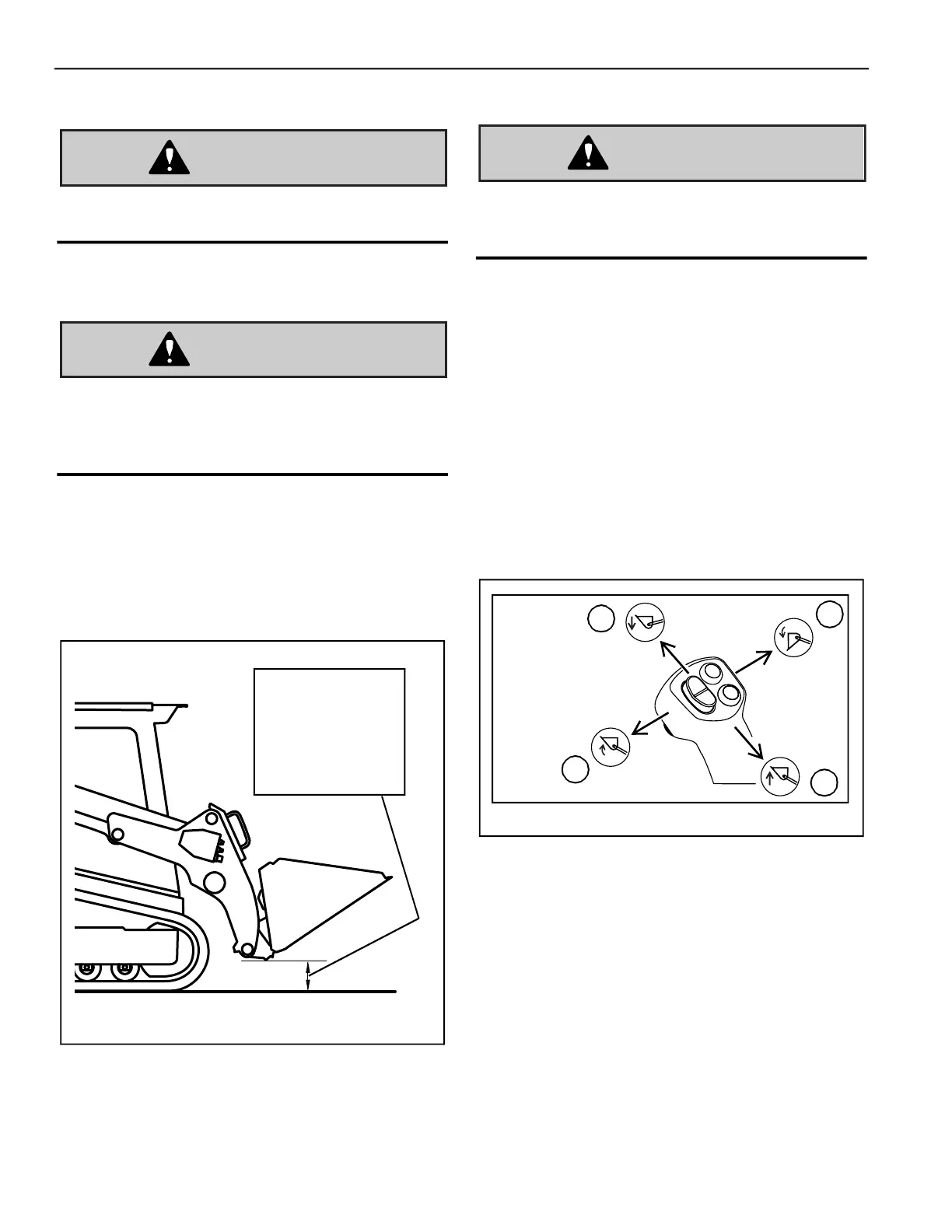

ISO Pattern Lift Arm Operation Controls

ISO pattern lift arm operation is controlled

exclusively using the right control joystick (Fig. 89):

A. Push the right joystick forward to lower the

lift arm.

IMPORTANT:

The lift arm can be lowered if the

engine is off by turning the ignition key clock-

wise to the first detent and pressing the float

button on the right joystick (See “Lift Arm Float”

on page 99).

B. Pull the right joystick backward to raise the

lift arm.

Fig. 88 – Transport Position

• 200-300 mm (8-12”)

above ground,

adjusted to clear

obstacles.

• As low as safely

possible.

Fig. 89 – ISO Pattern Lift Arm Operation

ISO

Control

Pattern

(Right

Joystick)

C

A

B

D

Loading...

Loading...