Operation

Printed in U.S.A. 93 50940411/G0219

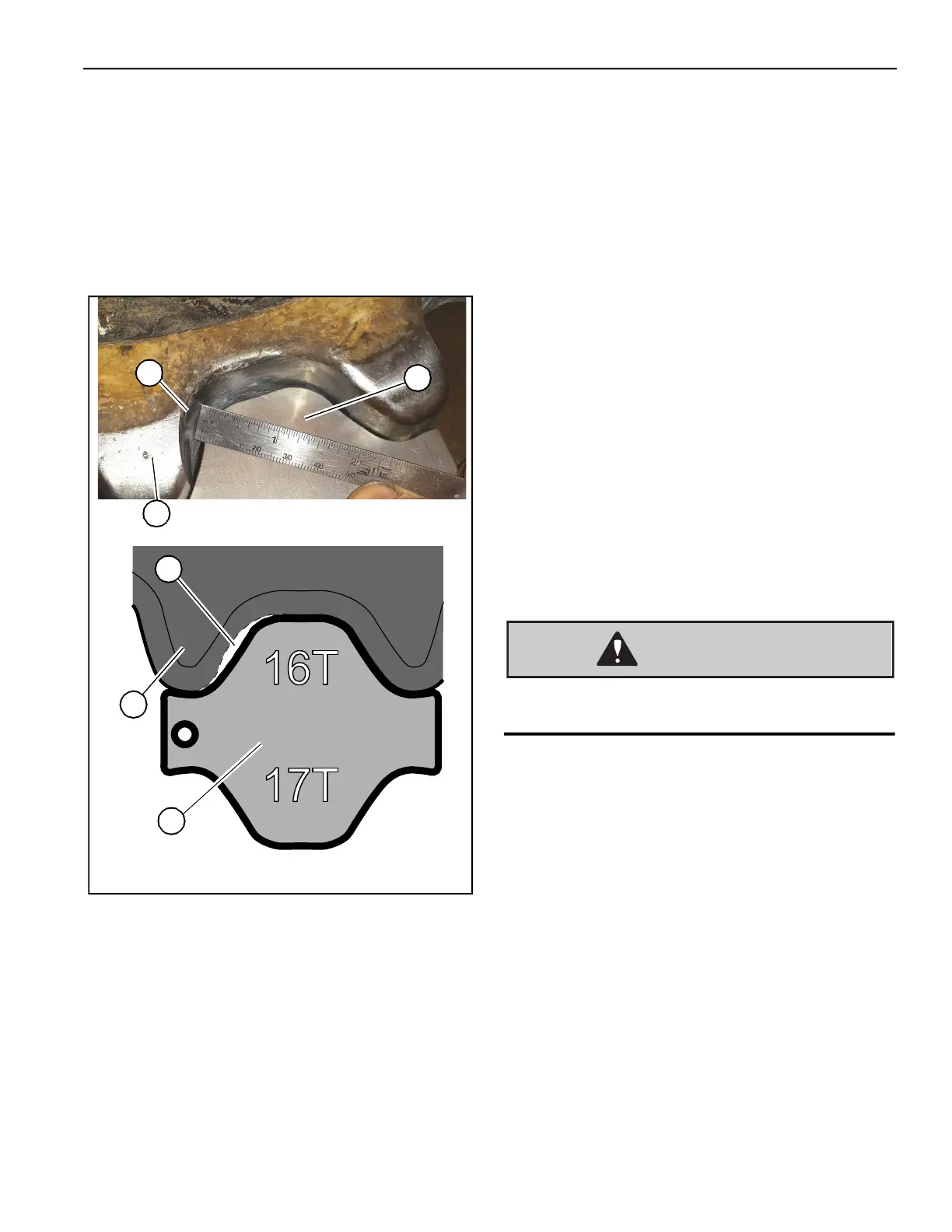

Sprocket Tooth Wear and Track Life

Worn sprockets are a typical cause of track damage

and abnormal track noise. Check for sprocket wear

often. Sprocket wear (B, Fig. 85) normally occurs

along the sides and crests of the sprocket teeth (C).

Use the sprocket tooth wear gauge (A - Manitou part

# 50309811), included with the machine, to

determine exact sprocket tooth wear:

• Hold the sprocket tooth wear gauge (A) against

the sprocket teeth at the centerline of the sprocket

as shown in the photograph. Wear gauge (A) has

the same profile as the teeth on a new sprocket.

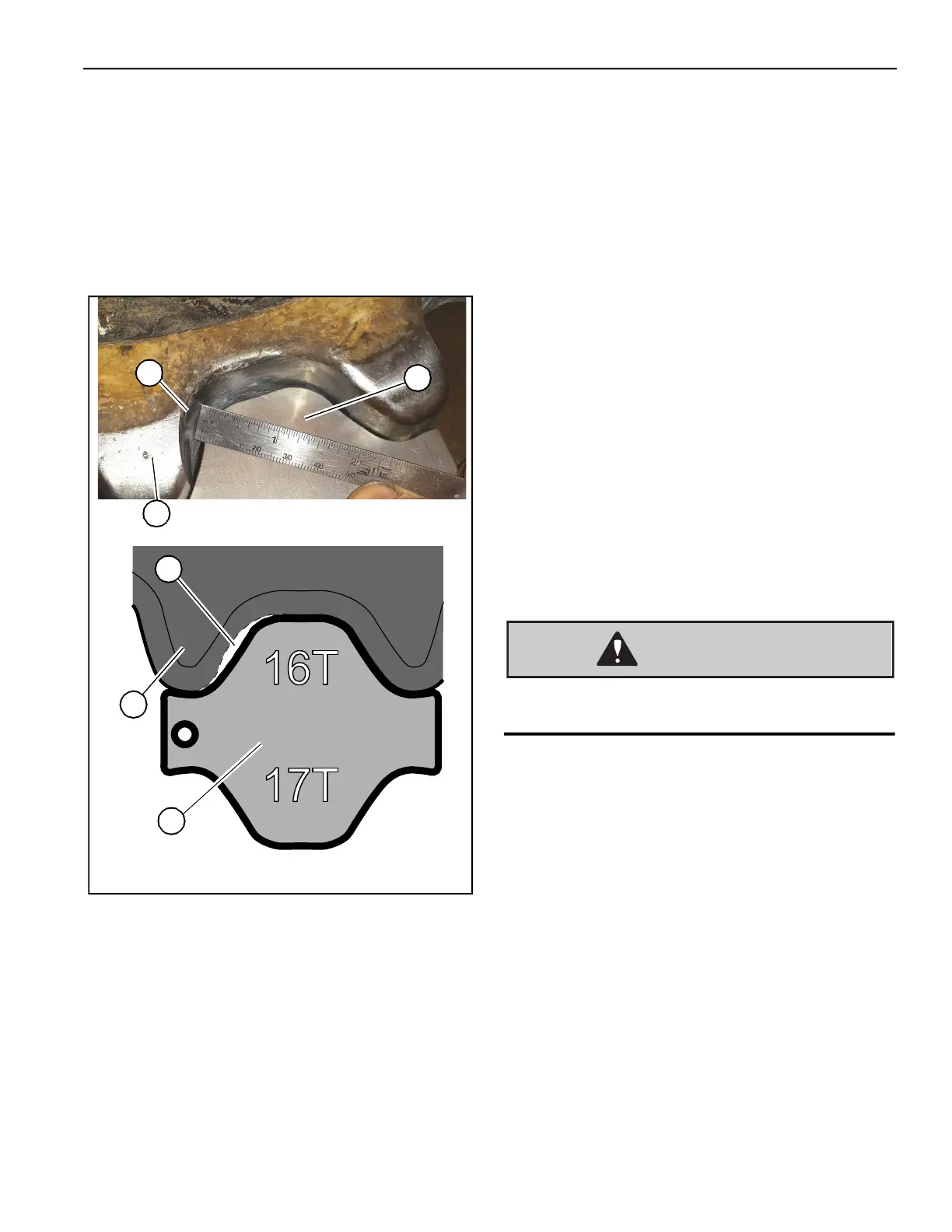

NOTE:

The sprocket tooth wear gauge is double-

sided; one side is marked “16T” and is used for

checking 16 tooth sprockets, the other side is

marked “17T” and is used for checking 17 tooth

sprockets.

• Sprocket wear is considered excessive if 1/8”

(4mm) of material is worn from any point along

the sprocket tooth profile.

• Worn sprockets cannot be repaired and should be

replaced. Refer to the parts manual for your

machine for sprocket service part numbers when

ordering. Rotating sprockets by swapping them

from one side to the other can extend their ser-

vice life, provided the wear is limited to one

direction of travel.

IMPORTANT:

New tracks perform better and last

longer with new sprockets because the mating sur-

face profiles are matched.

Always replace sprocket mounting hardware

when replacing or re-attaching sprockets.

Fig. 85 – Sprocket Tooth Wear Gauge

B

C

C

A

A

B

Loading...

Loading...