Operation

Printed in U.S.A. 117 50940411/G0219

6. Close the doors and the engine cover.

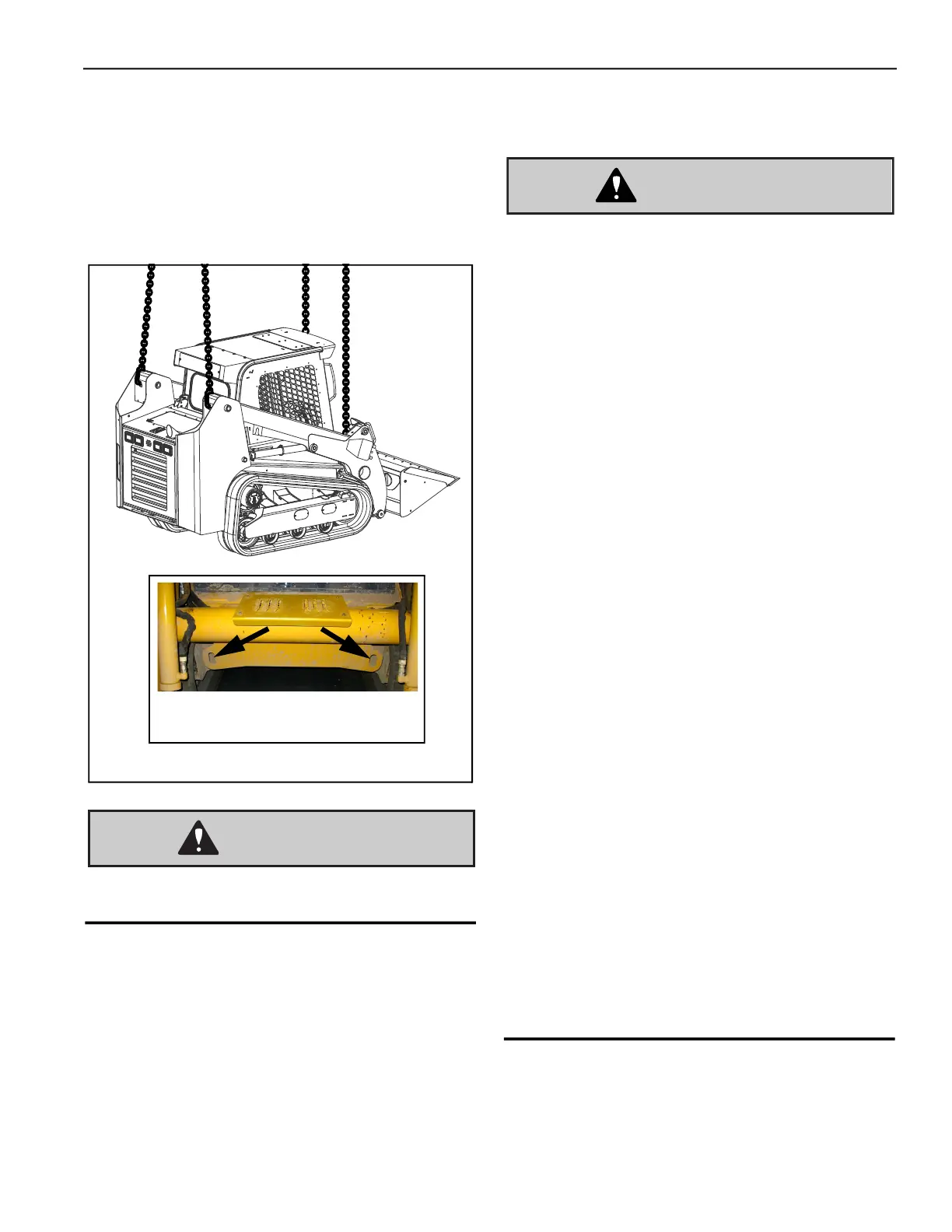

7. Connect spreader bar and chains to front and

rear lift points as shown. The spreader bar length

should allow for the lift chains to be as vertical

as possible during lifting. The lifting chain

lengths should allow for lifting the machine as

level as possible.

Do not fasten the lifting gear to the cab to crane

lift the machine.

8. Carefully raise the machine, keeping it as level

as possible.

Loading and Transporting the

Machine on a Transport Vehicle

Do not exceed the transport vehicle’s gross

weight rating and the gross axle weight rating

when loading and transporting the machine.

The transport vehicle must have sufficient

capacity for the size and weight of the machine.

See “Specifications” on page 35.

Make sure the load does not fall short of the

minimum axle load of the steering axle,

otherwise the transport vehicle’s steering could

be seriously affected.

Remove any mud, snow or ice from the tracks

on the machine to prevent slipping.

Position the machine at the lowest possible

position on the transport platform, with the

center of gravity of the load over center line of

the transport vehicle. Distribute partial loads to

ensure an even load on the axles on the

transport vehicle.

Secure the machine properly so it cannot slip,

slide, roll, tip over or fall, or cause the transport

vehicle to tip over under transport conditions.

Use anti-slip bases and linings, load-securing

straps and chains, clamping beams, protective

paddings, nets, edge protectors, etc. as needed

to properly secure the load. Consider all

possible transport conditions such as: heavy

braking, evasive maneuvers, and uneven or

rough roadways.

Adjust transport speed to the load, to the road/

traffic conditions and to the handling of the

transport vehicle.

Always use the proper tie-down points when

using straps and chains. See “Component

Identification” on page 13.

Fig. 118 – Crane Handling

Front Lift Point Tie-Down Location

Detail

Loading...

Loading...