Operation

Printed in U.S.A. 103 50940411/G0219

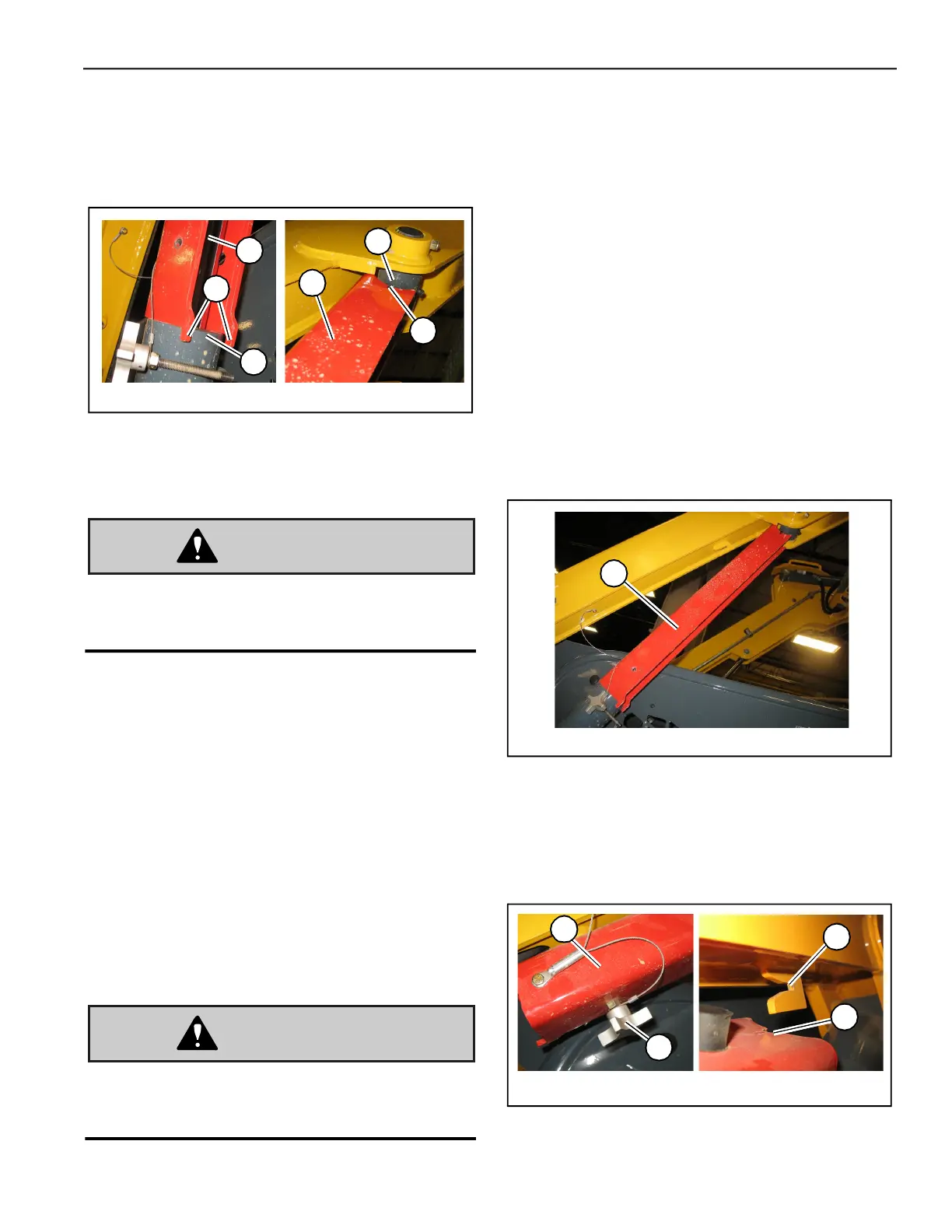

c. Position the lift arm support with the curved

end (E, Fig. 98) of the support tight against

the end of the cylinder rod (P), and tabs (T)

on the support hooked over cylinder tube

head (C) as shown.

9. Start the machine and lower the lift arm against

lift arm support (Z). Verify that lift arm support

(Z) is properly positioned as shown in Fig. 98.

The lift arm support device must be properly

positioned to prevent the lift arm from falling,

which could result in severe injury or death.

10. Shut off the engine.

11. Move the lift/tilt controls to verify that the

controls do not cause movement of the lift arm

and hitch plate.

12. Raise the safety bars/arm rests to apply the

parking brake and lock out the hydraulic

controls.

13. Unfasten the seat belt, remove the ignition key

and take it with you. Exit the machine using the

hand-holds.

Disengage Lift Arm Support

A second person on the outside of the machine

is required to assist with disengaging the lift

arm support.

1. Start the engine and raise the lift arm as high as

it will go.

2. Move the drive controls to the neutral position.

3. Shut off the engine.

4. Move the lift/tilt controls to verify that the

controls do not cause movement of the lift arm

and hitch plate.

5. Raise the safety bars/arm rests to apply the

parking brake and lock out the hydraulic

controls.

6. Stay in the machine in the operator’s position. A

second person, on the outside of the machine,

must:

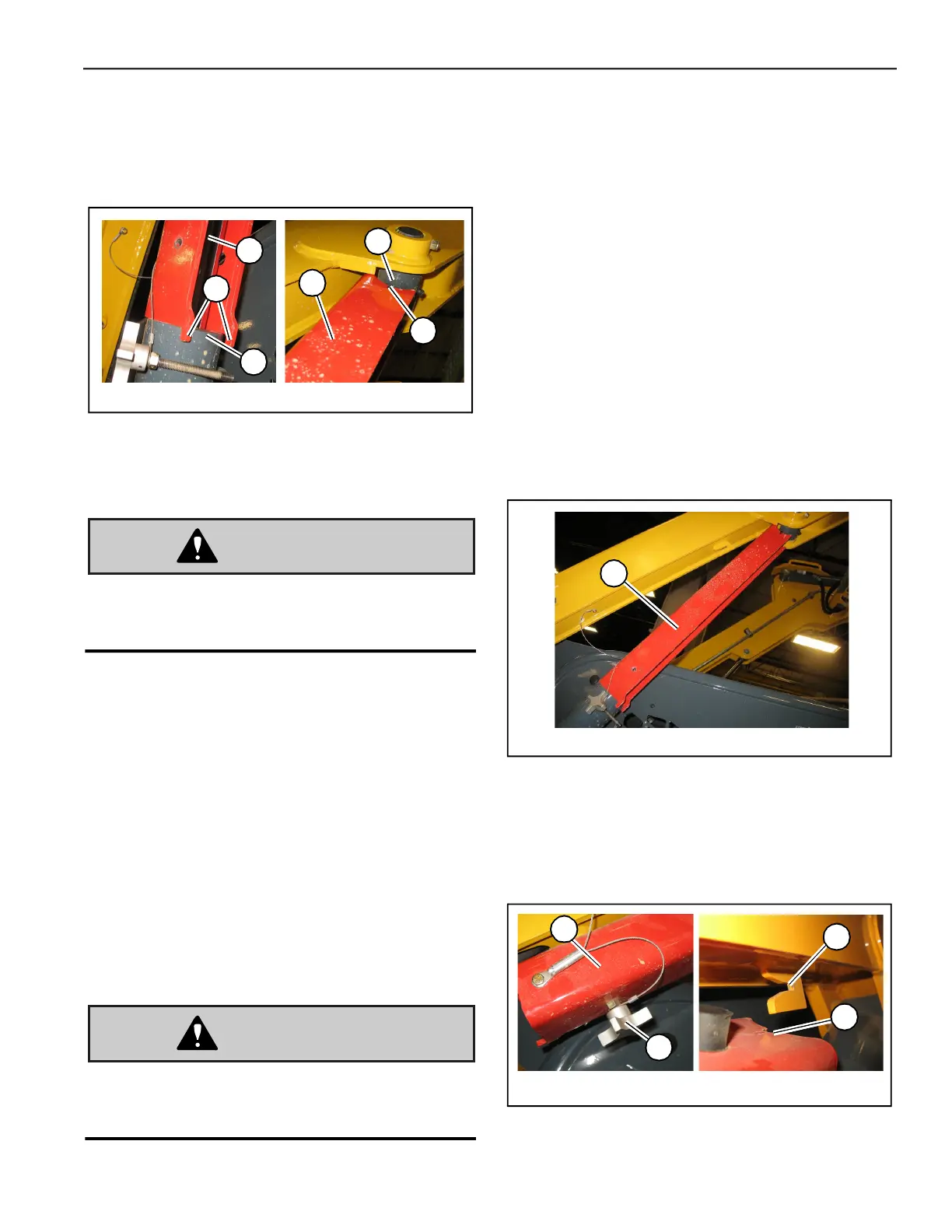

a. Remove lift arm support (Z, Fig. 99) from

the cylinder rod.

7. Securely insert notch (F, Fig. 100) on lift arm

support (Z) into retaining hook (N) on the lift

arm. Secure lift arm support (Z) in the storage

position using retaining fastener (Y). Tighten

fastener (Y) securely.

Fig. 98 – Lift Arm Support Proper Positioning

X

P

T

C

E

Z

Fig. 99 – Lift Arm Support Removal

Z

Fig. 100 – Lift Arm Support Storage Position

N

F

Y

Z

Loading...

Loading...