Maintenance

Printed in U.S.A. 133 50940411/G0219

8. Replace the radiator drain plug and tighten

securely.

9. Fill the radiator with coolant.

NOTE:

Use a low-silicate ethylene glycol-

based coolant, mixed with quality water and

supplemental coolant additives (SCAs) suitable

for heavy-duty diesel engines. See “Fluids/Lubri-

cants Types and Capacities” on page 35 and the

engine operation manual for additional informa-

tion.

10. Reinstall radiator cap and tighten securely.

11. Start and run the engine until it reaches operating

temperature.

12. Check the coolant level according to “Checking

Coolant Level” on page 131.

Belt Maintenance

Check belt condition monthly, or after every 100

hours of use. Replace or adjust if necessary.

NOTE:

On model RT250 machines, the belt is

tensioned by a spring idler and requires no

adjustment. Replace the belt if belt deflection

exceeds 0.6” (15 mm). Refer to the engine

operator’s manual for more details.

Checking and Adjusting Belt Tension

1. Perform the “Mandatory Safety Shutdown Pro-

cedure” on page 20.

2. Wait until the engine has cooled. See

“Maintenance and Service Safety Practices” on

page 25.

3. Open the engine cover according to “Engine

Access” on page 126.

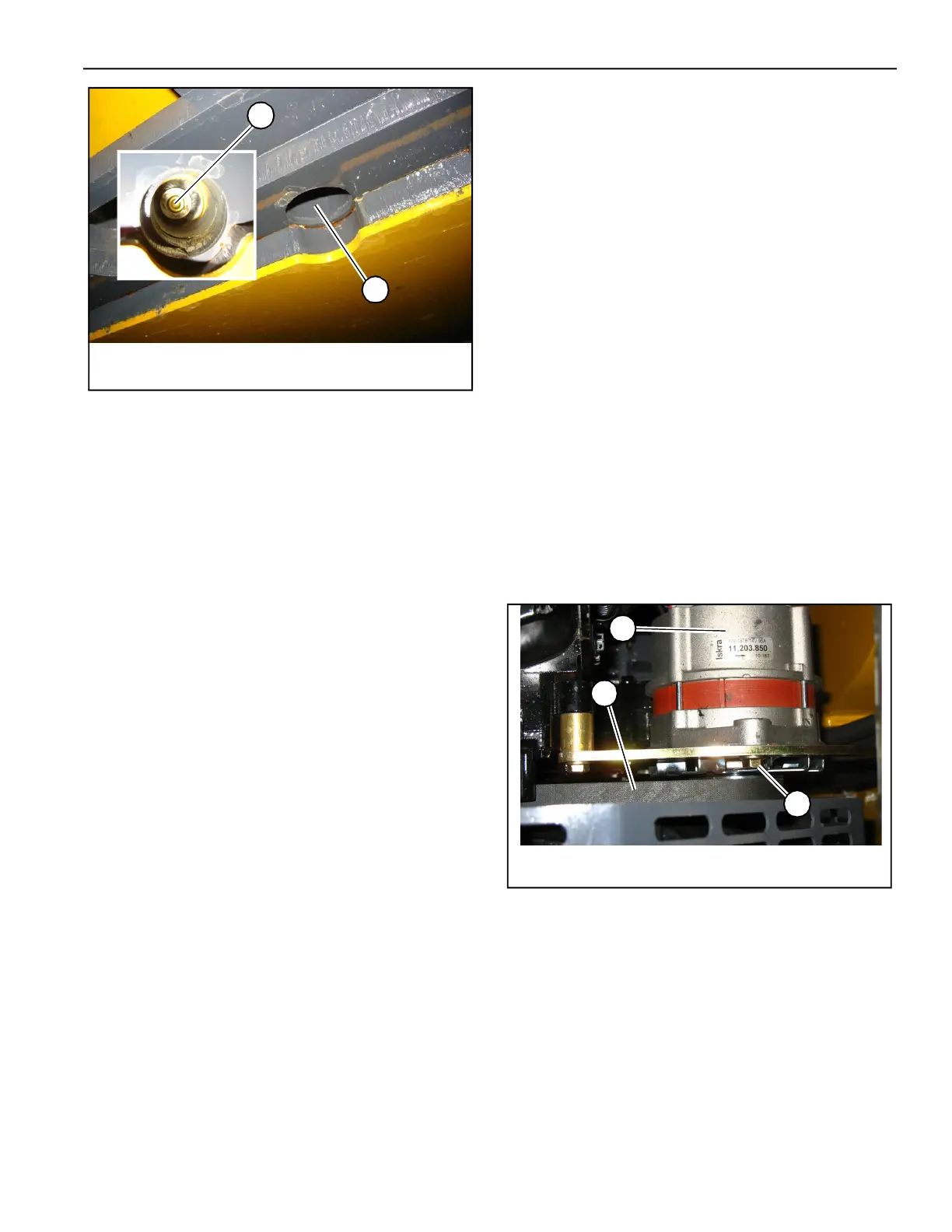

4. Inspect belt (A, Fig. 137) for damage. If

damaged, have belts replaced by an authorized

repair shop.

5. Press on belt (A) mid-way between pulleys to

check deflection. The belt should not deflect

more than 8 mm (5/16”).

6. If deflection is more than 8 mm (5/16”): Loosen

adjustment bolt (C) and rotate alternator (B)

outward until belt tension is correct. Tighten bolt

(C) and re-check belt tension.

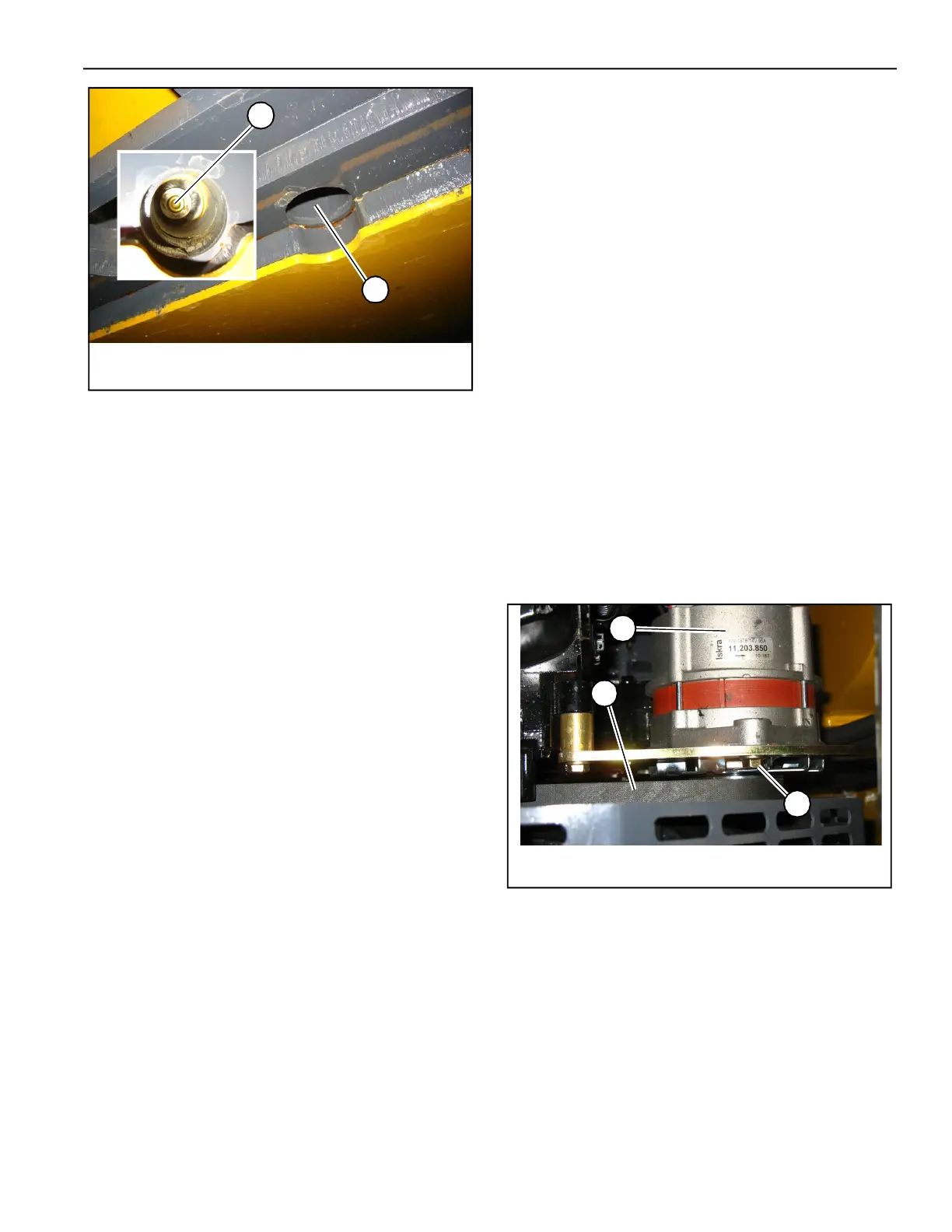

Fig. 136 – Radiator Drain Access

Y

X

Fig. 137 – Belt

B

C

A

Loading...

Loading...