Maintenance

50940411/G0219 138 Printed in U.S.A.

Hydraulic System Maintenance

Never use your hands to search for hydraulic

fluid leaks; use a piece of paper or cardboard to

find leaks. Escaping fluid under pressure can be

invisible and can penetrate the skin, causing

serious injury. If any fluid is injected into your

skin, see a doctor at once. Injected fluid MUST

be surgically removed, or gangrene may result.

Checking Hydraulic Oil Level

Check the hydraulic oil level daily before starting

the machine, or after every ten hours of use.

1. Park the machine on a level surface. Fully retract

all hydraulic cylinders (lift arm down; bucket

flat).

2. Perform the “Mandatory Safety Shutdown

Procedure” on page 20.

3. Wait until the engine has cooled. See

“Maintenance and Service Safety Practices” on

page 25.

4. Open the engine cover according to “Engine

Access” on page 126.

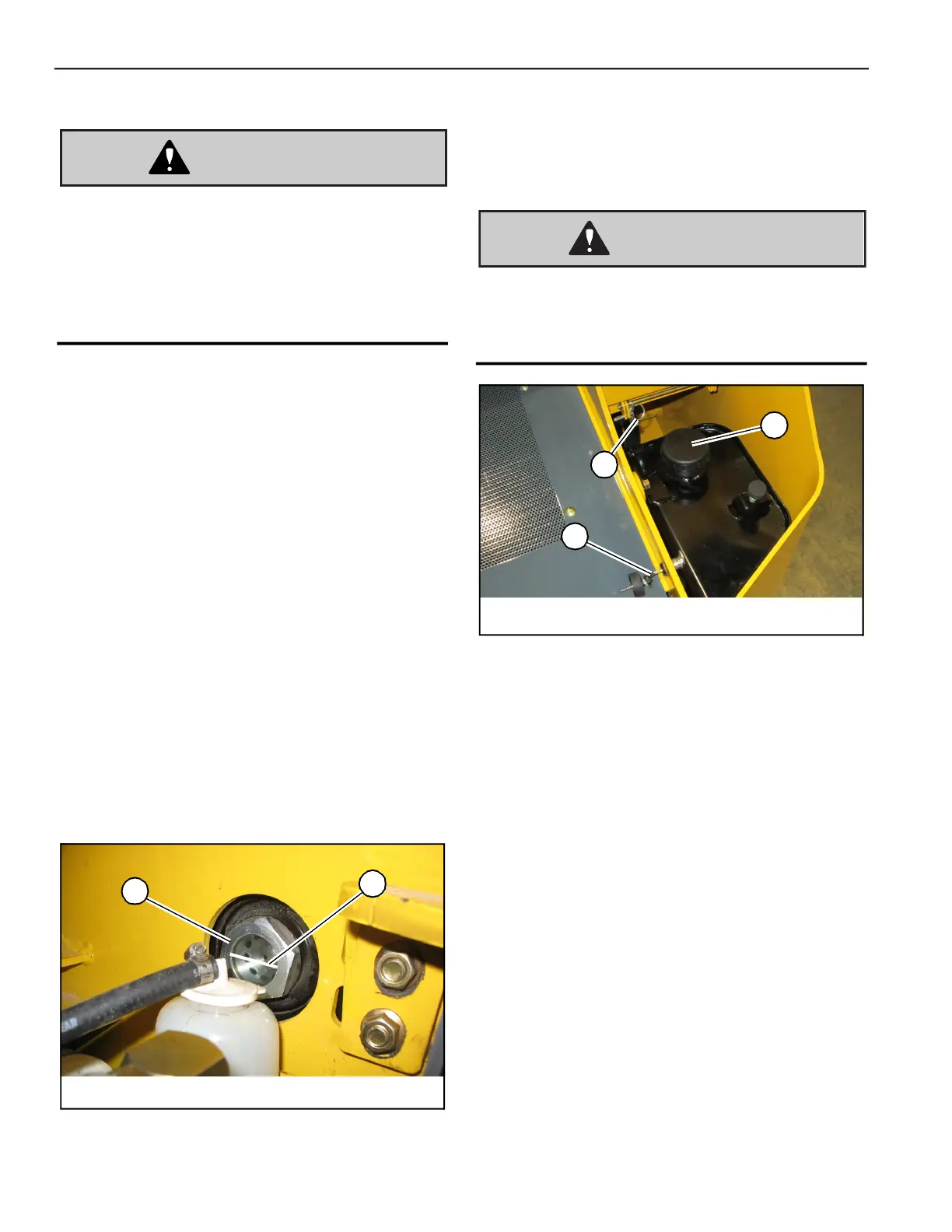

5. Check the level of the hydraulic oil in the sight

gauge (Y, Fig. 143) located in the right engine

compartment wall. The oil level should be in the

middle of the sight gauge (A).

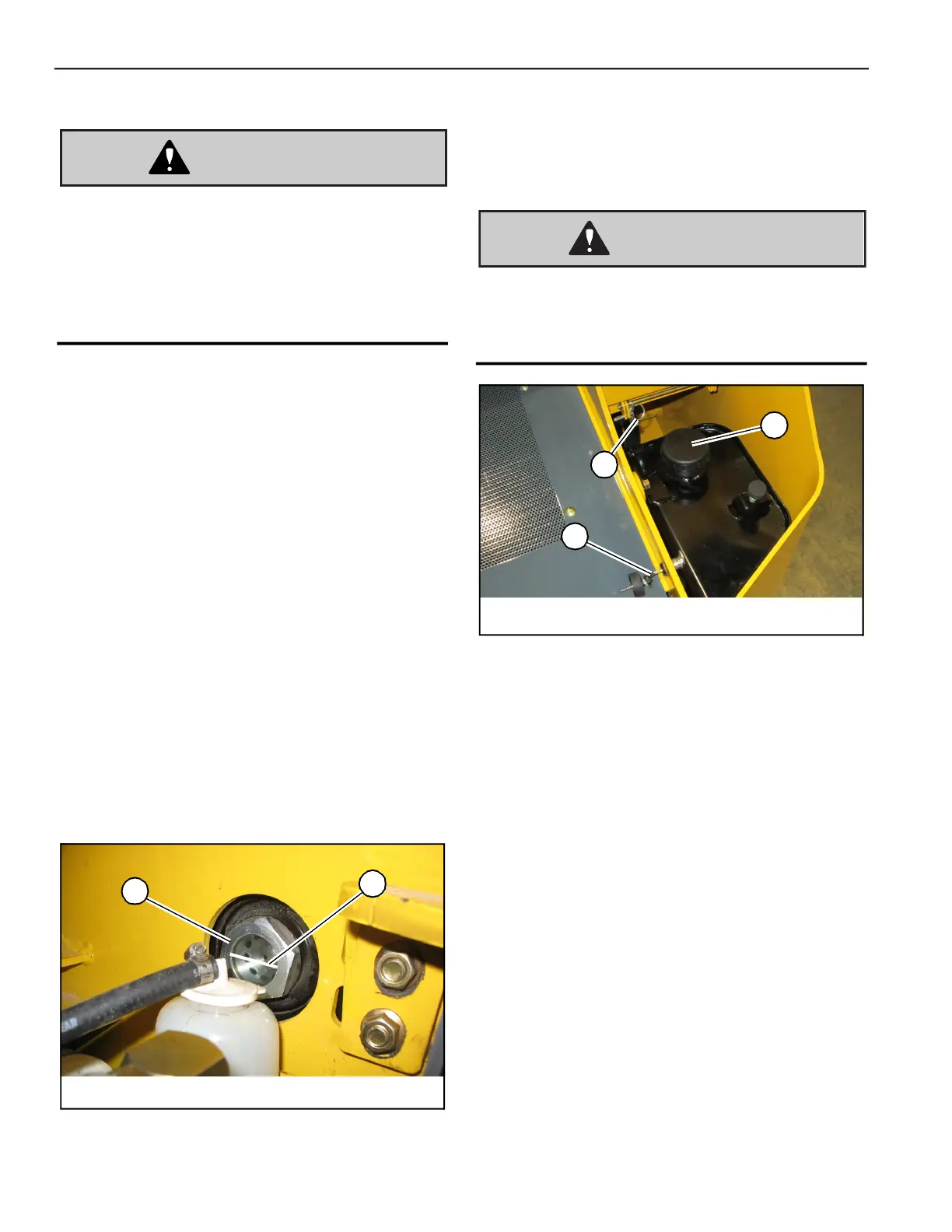

6. If the hydraulic oil level is low, use the ignition

key to unlock and open the hydraulic tank cover

(H, Fig. 144), located on the top right of the

machine next to the top engine cover. Lock tank

cover open using pin (D).

Always prop the hydraulic tank cover open

using pin (D). Severe injuries can result if the

battery compartment cover falls on hands and/

or fingers.

7. Remove the hydraulic tank breather/oil fill cap

(P).

NOTE: Slowly remove the hydraulic breather/oil

fill cap (P). Allow the pressure to escape before

completely removing the cap.

8. Add hydraulic fluid as required. See “Fluids/

Lubricants Types and Capacities” on page 35 for

proper hydraulic oil grade and type.

IMPORTANT:

Do not mix different types/grades of

hydraulic fluids.

Reinstall and tighten the oil fill cap. Close and

lock the hydraulic tank cover.

Y

Fig. 143 – Hydraulic Oil Level Sight Gauge

A

P

D

H

Fig. 144 – Hydraulic Oil Fill

Loading...

Loading...