3 Piping work and

refrigerant charge

93

3

SMGB0077 rev.0 - 01/2013

3.2 Copper pipes, sizes, connection and insulation

3.2.1 Copper pipes and sizes

C A U T I O N

• The copper pipe used in the refrigeration installations is different to the copper pipe used in installations

carrying domestic or heating water.

• The copper pipe for refrigeration installations is especially treated for outdoors and indoors. The interior

surface nish makes it easierfor the refrigerant to circulateand withstands the action ofthe lubricant oil

applied to outdoor equipment.

Prepare the copper pipes provided by the supplier.

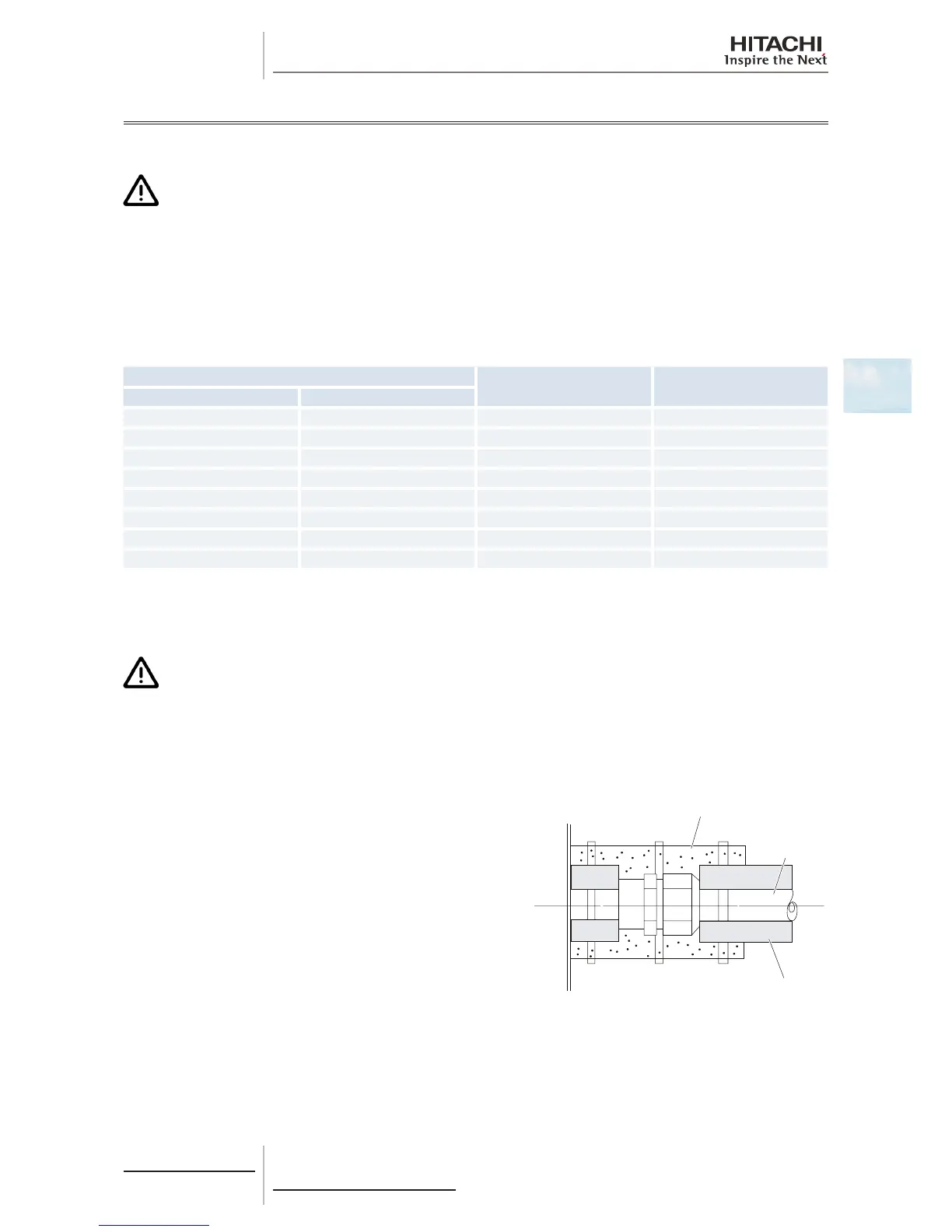

Select the pipe with the appropriate diameter and thickness. Use the table below to select the most appropriate pipe:

Nominal diameter

Thickness mm Supply

mm Inches

Ø6.35 1/4 0.80 Roll

Ø9.52 3/8 0.80 Roll

Ø12.7 1/2 0.80 Roll

Ø15.88 5/8 1.00 Roll

Ø19.05 3/4 1.00 Pipe

Ø22.20 7/8 1.00 Pipe

Ø25.40 1 1.00 Pipe

Ø28.60 1-1/8 1.00 Pipe

Always use clean copper pipes with no signs of knocks or cracks. Make sure there is no dust or dampness on the inside.

Before you install the pipes, clean the inside with oxygen-free nitrogen gas to eliminate any remains of dust or other

substances.

C A U T I O N

• Do not use hand saws, circular saws, abrasive grinders or other tools that generate shavings.

• Strictly follow national or local regulations regarding occupational health and safety.

• Wear appropriate means of protection during cutting or brazing operations and installation (gloves, eye

protection, etc).

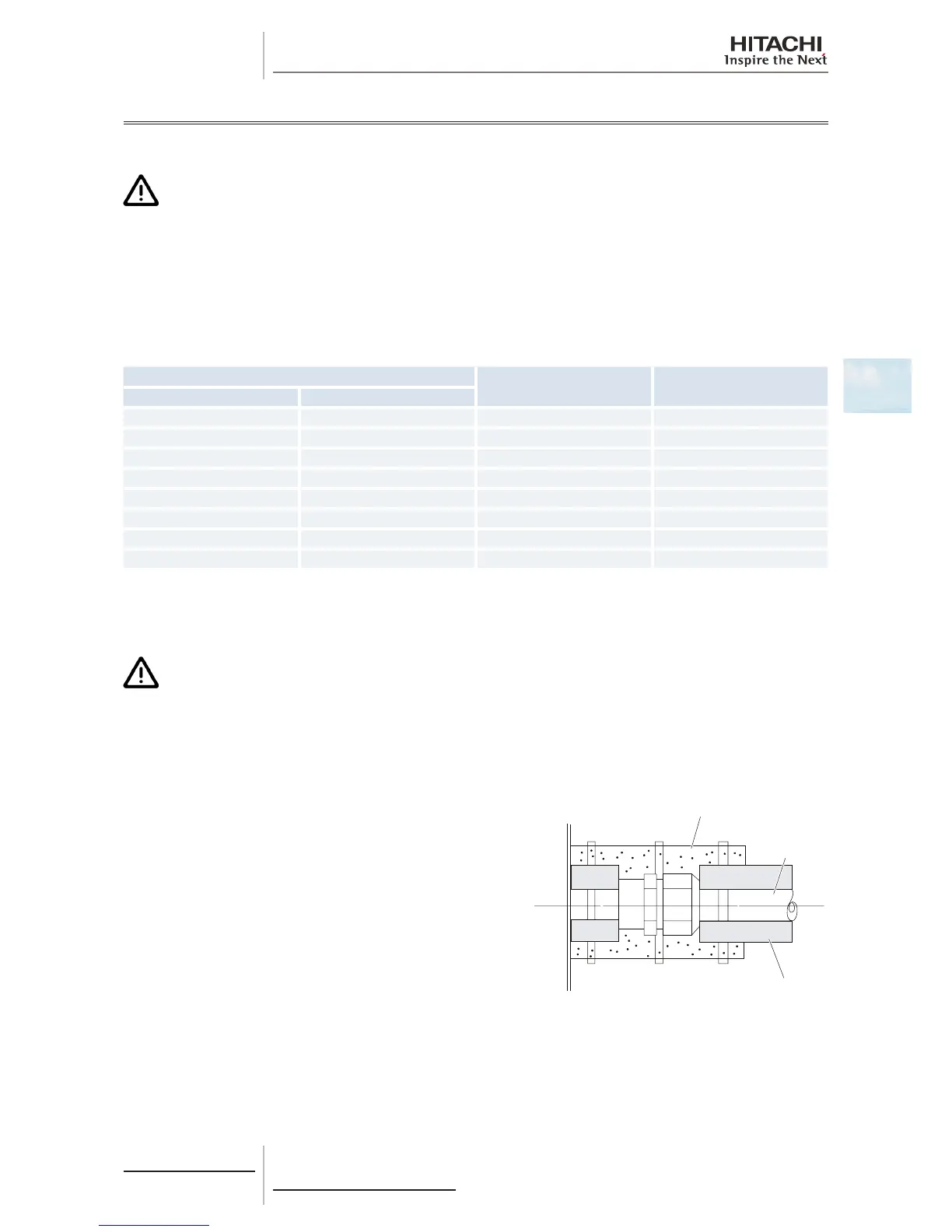

On completing the installation of the refrigerant pipes -B-, insulate

them appropriately using suitable insulating material -A- and seal

the open space between the holes made and the pipe, as shown

in the gure.

A

A

B

Loading...

Loading...