Chapter 9 Troubleshooting

268

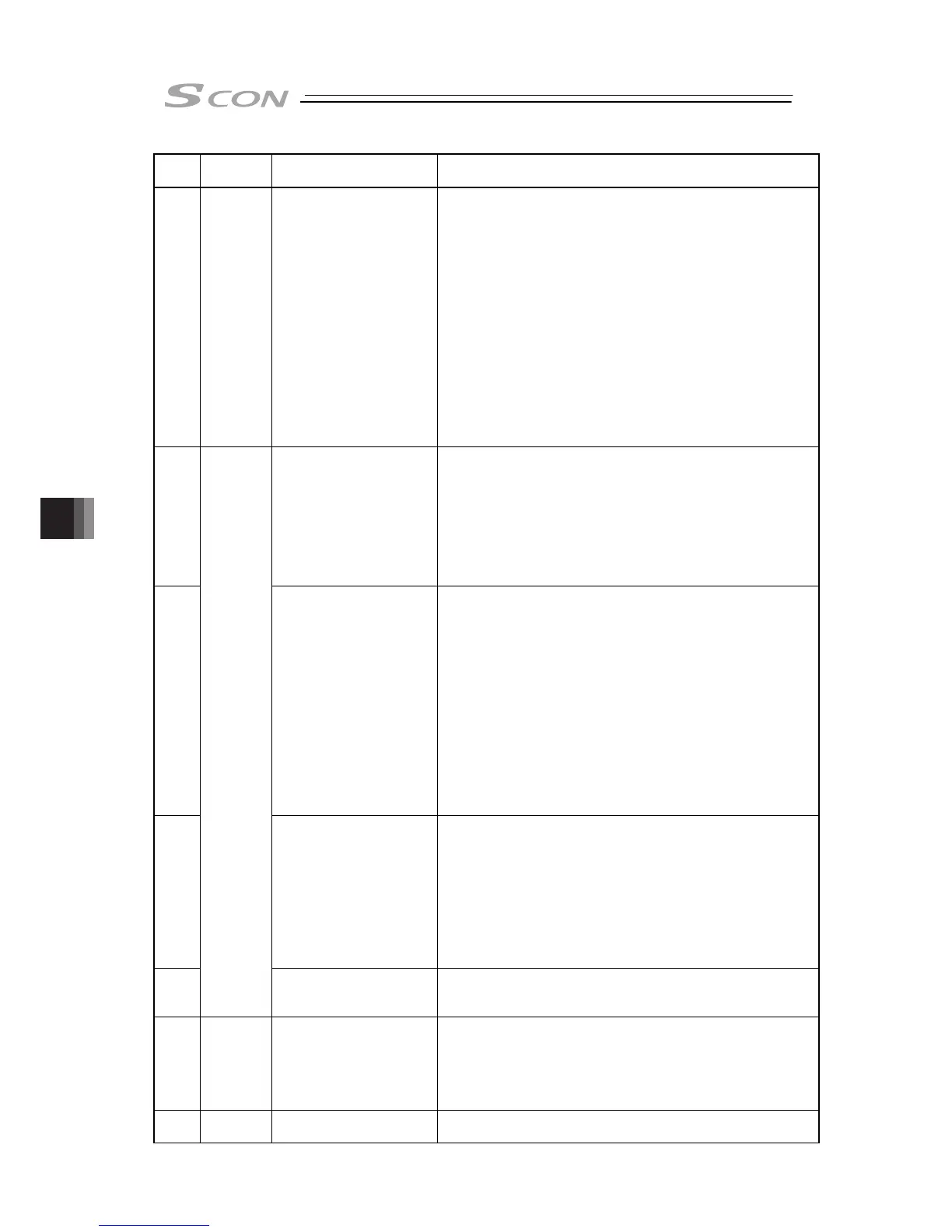

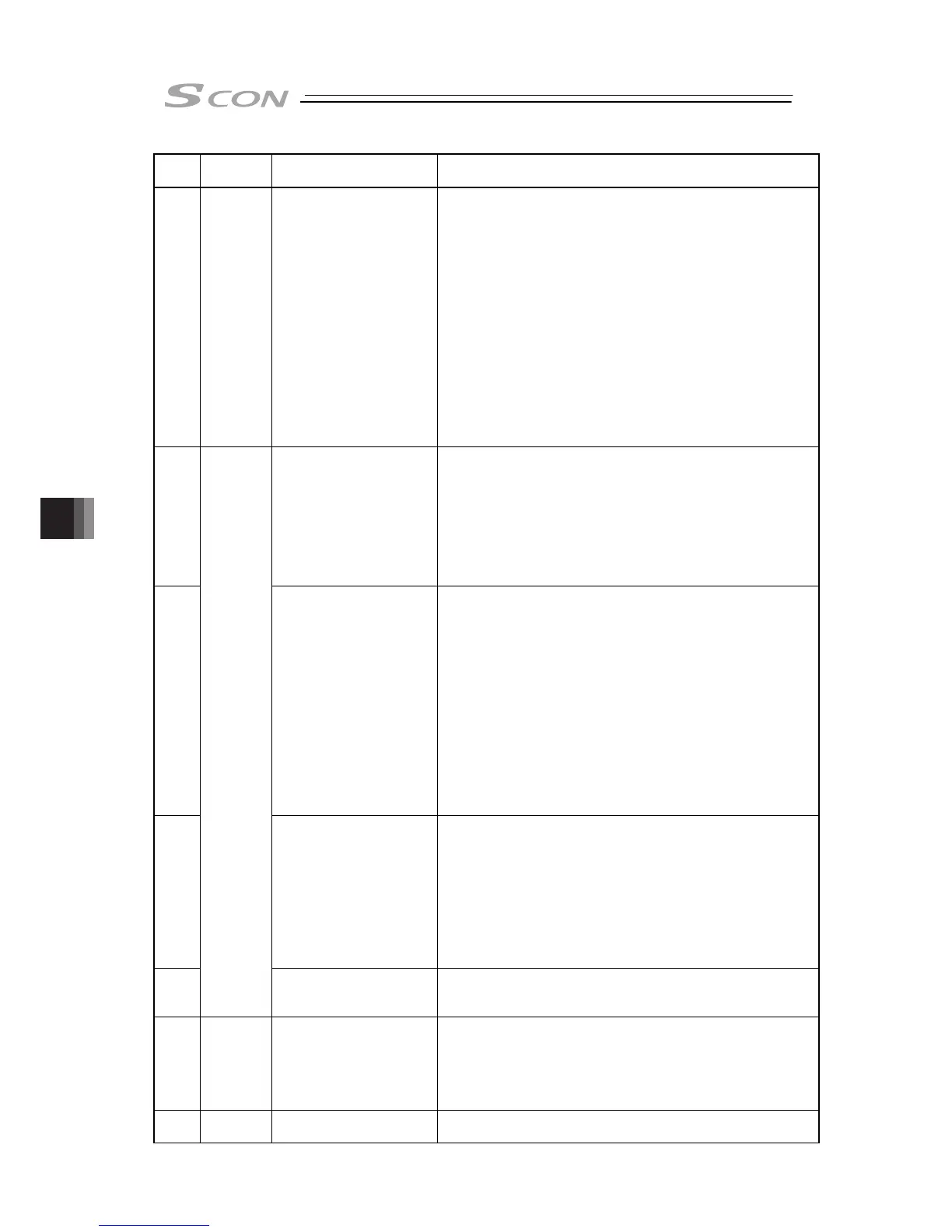

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

0E6 Encoder count error Cause : This error code appears when the encoder cannot

detect the position information properly.

1) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

2) Foreign matter is deposited on the code wheel.

3) The position relationship between the code

wheel and photo sensor changed due to shaft

center shift caused by application of excessive

external force, etc.

4) Faulty encoder board component

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

For the case of 2), 3) or 4), it is necessary either to

clean the code wheel, adjust the installation

position, replace the motor unit or replace the

actuator. In any case, please contact IAI.

0E7 A-, B- and Z-phase wire

breaking

Cause : Encoder signals cannot be detected correctly.

1) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

2) The encoder itself is faulty.

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

If the cables are normal, faulty encoder is

suspected. Please contact IAI.

0EE Absolute encoder error

detection 2

Cause : This is the condition where the position information

can not be detected in the absolute encoder.

1) Voltage drop of absolute battery.

2) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

Treatment : 1) Check the PIO battery alarm output (*BALM) and

when it is turned OFF, replace the absolute

battery with new one.

2) Check if any wire breakage on a connector and

the condition of wire connections.

Whichever action is taken under 1) or 2), an

absolute reset must be performed.

If the cables are normal, faulty encoder is

suspected. Please contact IAI.

0EF Absolute encoder error

detection 3

Absolute encoder is not detecting the position information

properly. (ABS encoder overspeed error)

Cause : This error occurs in such cases as the speed

exceeded the tracing acceleration speed limit in the

drop by the brake release at the power cutoff of the

absolute type vertical axis. (This condition should

not occur in normal conditions of use. Take

sufficient note on forced brake release.)

Treatment : If the error is occurred, it is necessary to absolute

reset.

0F0

Cold start

Driver logic error Cause : Exceeded load, parameter (motor type)

mismatched, noise, malfunction of controller, etc.

Treatment : Please contact IAI.

0F1

Operation

release

Field bus link error Cause : This error occurs when the link of the fieldbus is

disconnected in a fieldbus type controller.

Treatment : It can be considered that there is a setting error in a

fieldbus related parameter, setting error in the

master, connection error in fieldbus cable or

interruption by noise.

0F2

Cold start

Field bus module error Cause : A Field bus Module error was detected.

Treatment : Check the Field bus related parameters.

Loading...

Loading...