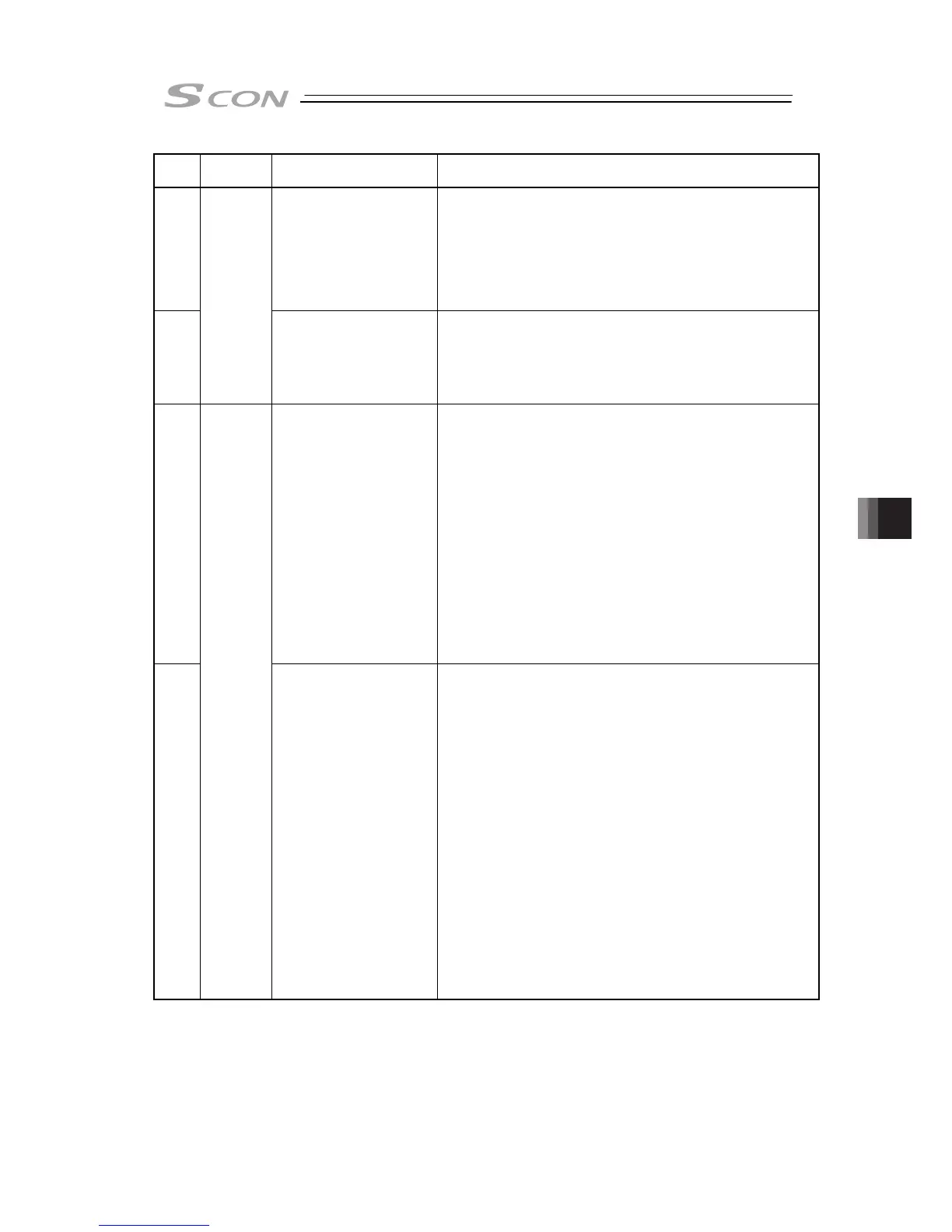

Chapter 9 Troubleshooting

267

Alarm

Code

Alarm

Level

Alarm Name Cause/Treatment

0E2 Loadcell communication

error

Cause : There was a communication error during the

communication with the loadcell.

Treatment : 1) Review wiring of loadcell cables and others.

2) Effect of noise is suspected. Check the presence

of noise source around the loadcell.

3) Replace the loadcell if it may be faulty.

4) Replace the controller if it may be faulty.

In cases 3) and 4), please contact IAI.

0E3

Cold start

Loadcell error Cause : Loadcell power error, hardware error such as board

overheat or EEPROM error occurs.

Treatment : 1) The effect of noise may be possible. Check the

presence of noise source around the loadcell.

2) Replace the loadcell if it may be faulty. Please

contact IAI.

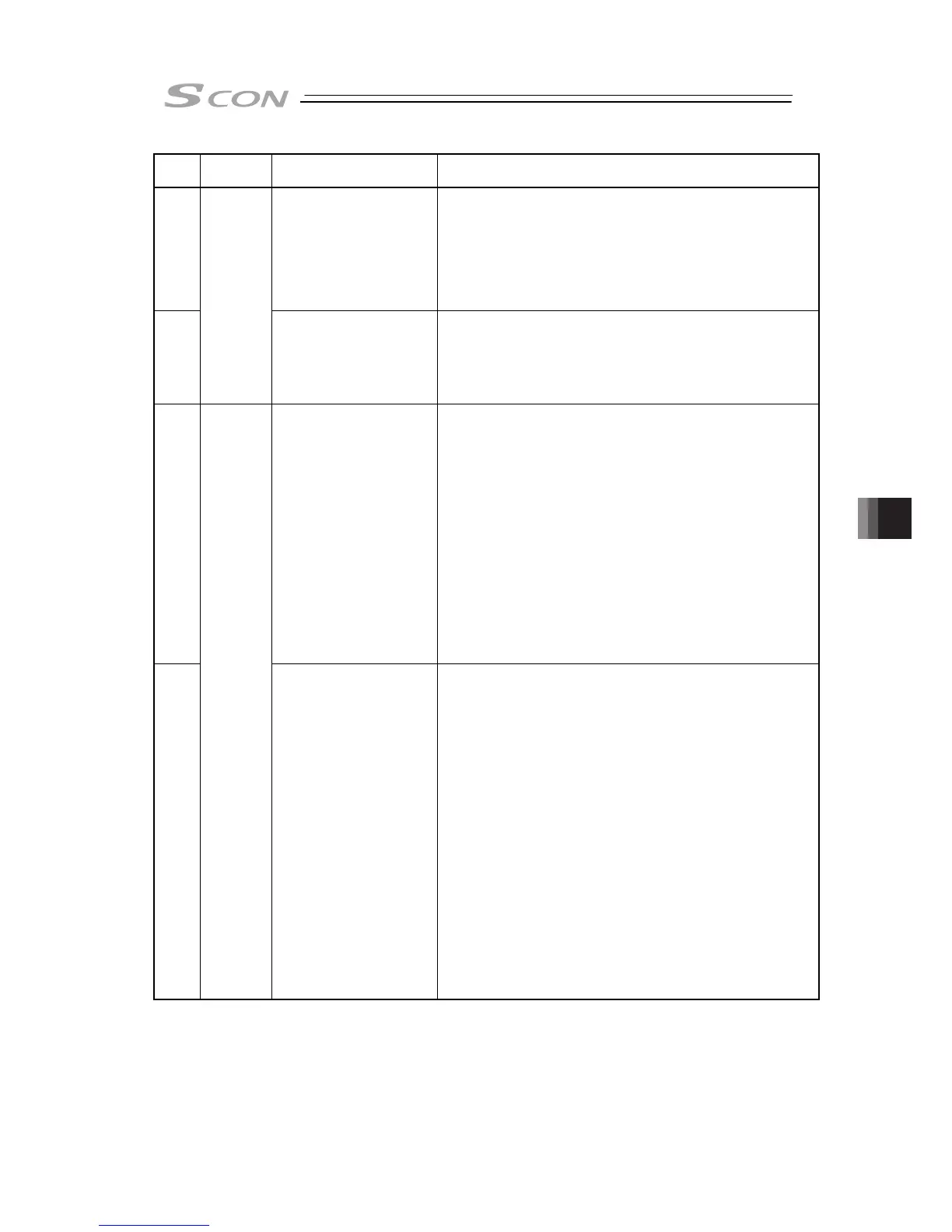

0E4 Encoder send error Cause : The data sending and receiving between the

controller and encoder is conducted by the serial

communication. This error indicates that the data

sent from the controller was not received properly at

the encoder side.

1) Effect of noise

2) One or more communication ICs installed on the

encoder board are faulty.

3) One or more communication ICs installed on the

controller board are faulty.

Treatment : 1) Interrupt the power to the peripheral equipment

and activate only the actuator. If any error does

not occur, it might be caused by noise. Take

proper measures against noise.

If 2) or 3) is the case, the encoder or controller must

be replaced.

If the cause cannot be specified, please contact IAI.

0E5

Cold start

Encoder receipt error Cause : This shows the data was not received in normal

condition from the encoder side to the controller.

1) Cable breakage of encoder cable or connector

connection failure.

(If the detail code in the error list of the teaching

tool is 0001H.)

2) Effect of noise.

(If the detail code in the error list of the teaching

tool is 0002H.)

3) Malfunction of component (communication part)

inside the actuator.

4) A faulty part inside the controller (communication

part).

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

2) Interrupt the power to the peripheral equipment

and activate only the actuator. If any error does

not occur, it might be caused by noise. Take

proper measures against noise.

If 3) or 4) is the case, it is necessary to replace the

actuator (motor part) or controller.

If the cause cannot be specified, please contact IAI.

Loading...

Loading...