Operating Procedures Tunnel Master

Jr. User Manual—Version 3.0

42 January 2016

WET DOWN WASH

The Wet Down process is the first step that the opening person should do to

prepare the wash for the first customer. When selected, the process is setup

to activate all relays (outputs) which have been designated to turn on during

the Wet Down cycle. The

cycle time is setup in the Wash Settings menu. By

wetting down the cloth equipment and perhaps charging the foaming

manifolds in the wash, the wash will be prepared to process the first vehicle,

and provide a more consistent wash to the customer.

Follow these

steps to start a wet down at the Tunnel Master

Jr. display:

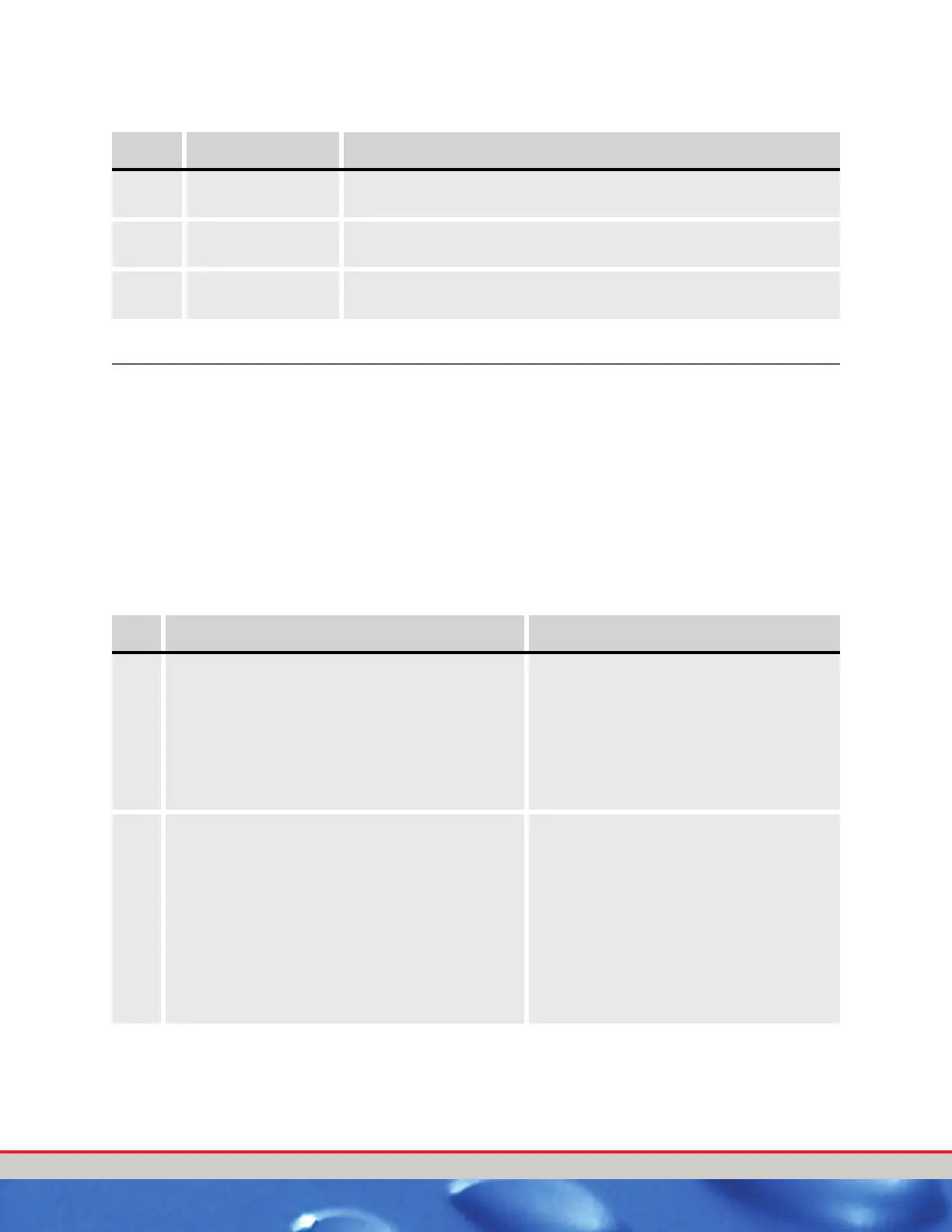

3 Configure Wash Allows user to configure wash settings and services, explained in-depth.

See “Wet Down Wash” on page 42.

4 View Counts This menu gives the ability to view counts, number of times the various

services have been processed during the current shift.

5 Print Reports From this menu option a user can print various financial r eports, if there is

an optional report printer attached to the controller.

Table 3: Main Wash Menu

Item Menu Option Function

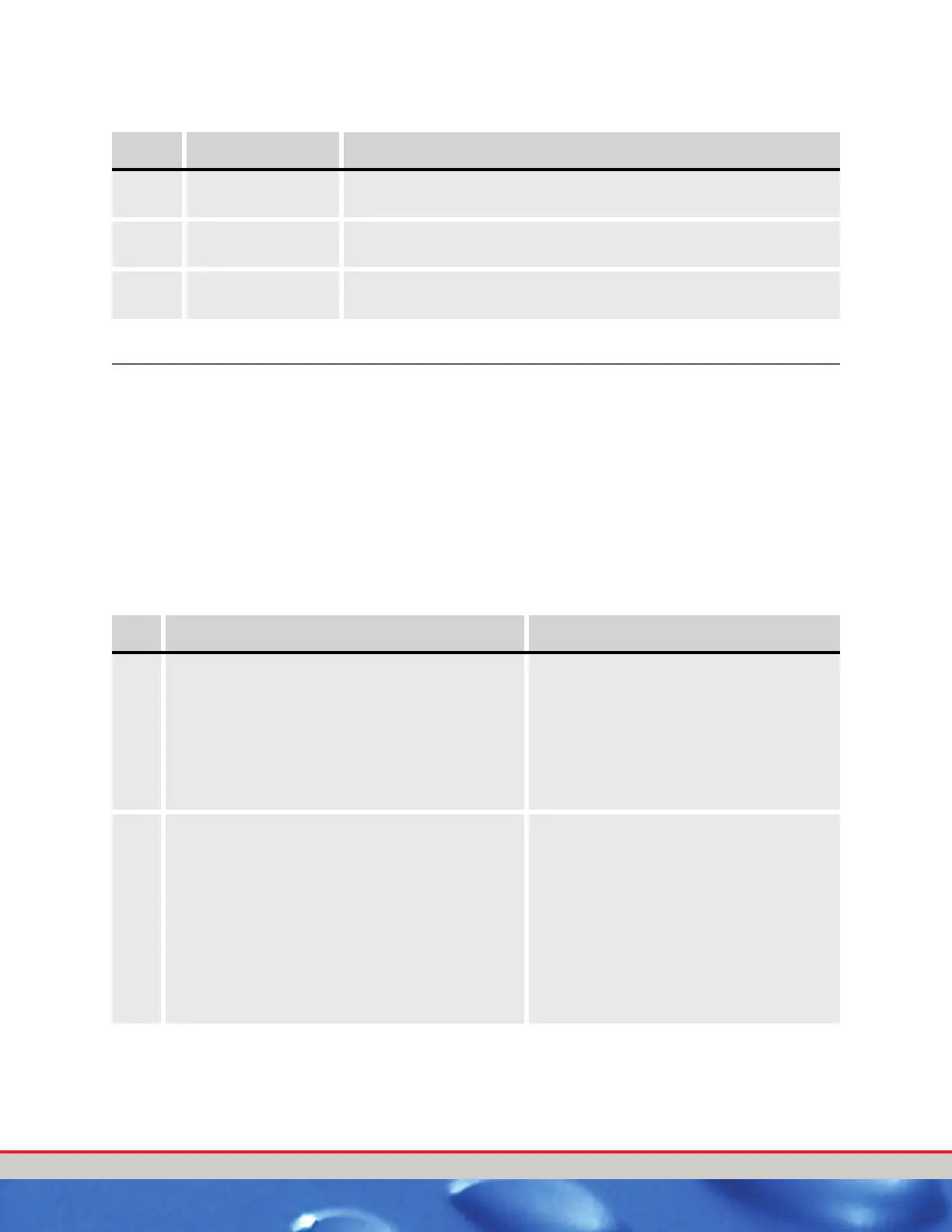

Table 4: Wet Down Wash Instructions

Step Action Screen Displays

1

From the Tunnel Master

Jr. display panel, press the

Menu button to access

the main menu.

NOTE: If a password has been set, it will be necessary

to enter the password before the main menu can be

accessed.

[1] Shift Break[4] View Counts

[2] Wet Down Wash[5] Print Reports

[3] Configure Wash

2 From the display panel numeric keypad, press the

numeric 2 key to select

Wet Down Wash.

NOTE: The relays will be activated and you will be

returned to the main display screen. A second to

second countdown will start next to the word

WETDOWN. This system will continue counting down

until it reaches 0 and then shut all of the activated

relays off.

ICS Tunnel Controller 10:25:35 PM VER 1 REV

5.1104/15/2002

WETDOWN 085 SECSCARS 0000

Loading...

Loading...