DCE80-100E

Technical Handbook

General

11

P.Group 00

TDCE01

04GB

To reduce the risk of settlement of the material and the

associated reduction in the preloading force if the hardness of the

surface supporting the bolt head or nut is lower than 200 HB, a

washer should be fitted under the bolt head and nut. This is not

applicable if flanged bolts or flanged nuts are used.

When tightening is carried out, the specified torque should be ap-

plied without pause, to ensure that the torque wrench will not be

tripped by the static friction before the joint has been tightened to

the specified torque.

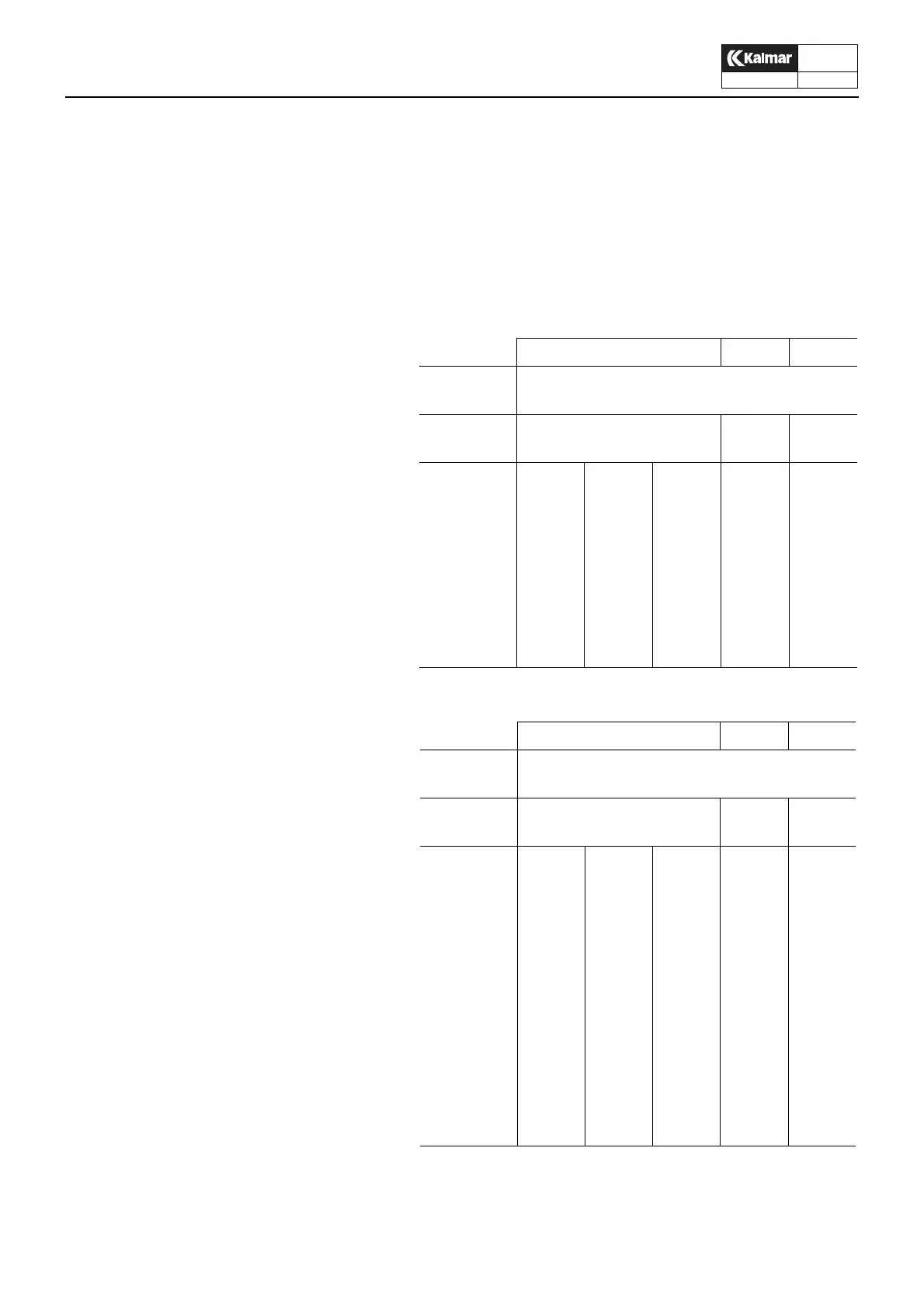

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

M

12311

4

5

6

8

10

3,2

6,4

11

26

52

2,9

5,7

9,8

24

47

3,6

7,2

12,5

30

59

4,6

9,1

16

38

74

5,5

11

19

45

89

12

16

20

24

30

91

220

430

750

1480

81

198

386

668

1317

103

250

49

848

1672

128

313

620

1050

2080

154

375

732

1270

2500

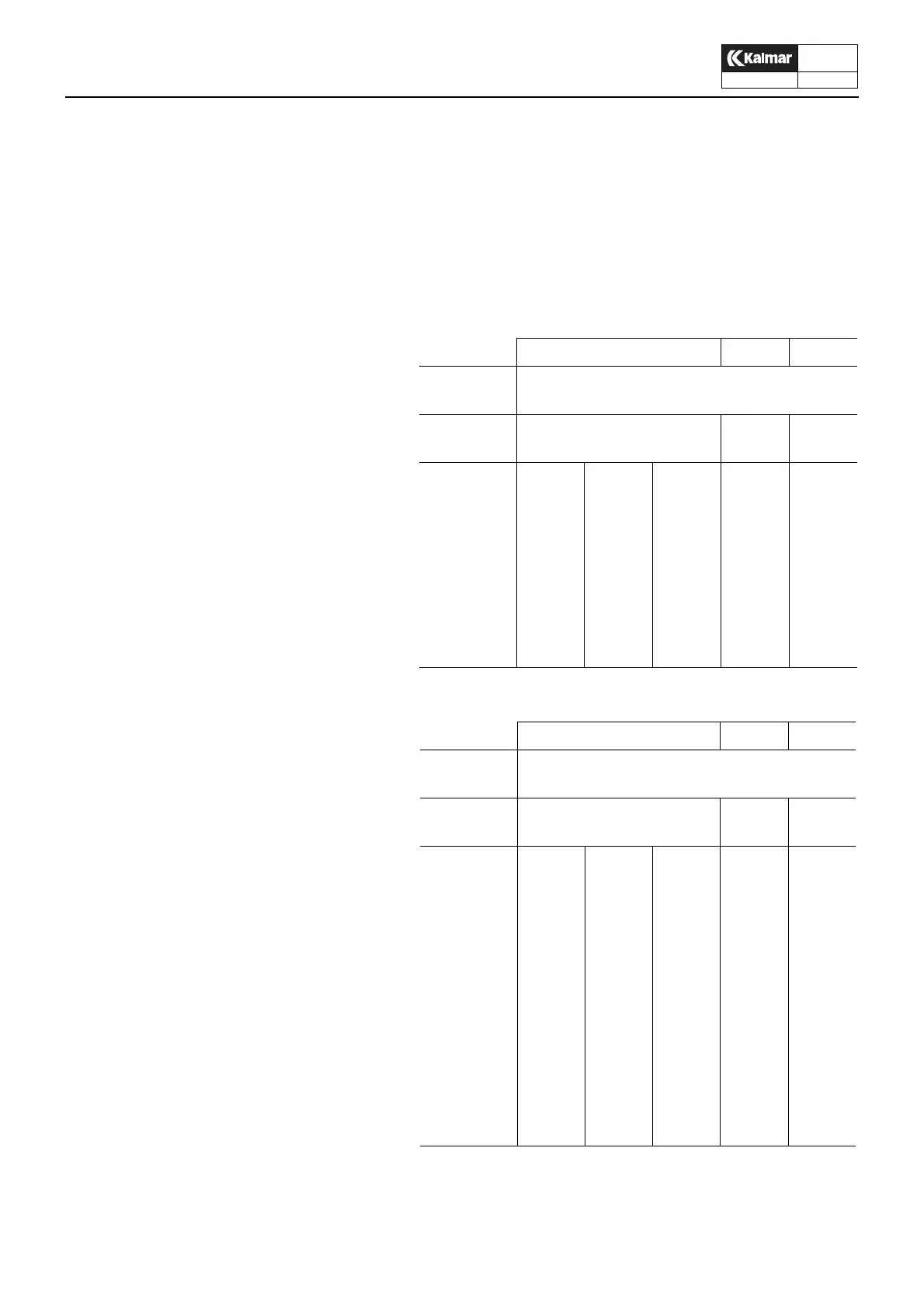

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

UNC

12311

1/4

5/16

3/8

7/16

1/2

12,5

25

44

70

107

11,1

22,3

39

62

95

14,1

28,3

50

79

121

17,6

35

62

100

151

20

42

73

118

178

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

153

210

370

594

889

1260

1760

2320

3060

136

187

390

528

791

1120

1565

2065

2720

173

237

418

671

1005

1424

1990

2620

3455

216

298

524

839

1260

1780

2490

3280

4320

255

353

619

990

1480

2100

2940

3870

5100

Loading...

Loading...