DCE80-100E

Technical Handbook

Lifting mast and fork carriage

Service

11

P.Group 80

TDCE01

04GB

Inserting shims for sliding plates - general

1. Check the play in the mast and between the carriage and the

mast.

2. When a noticeable gap occurs, equivalent to a play of at

least 2 mm, reduce the play with shims.

3. When inserting the last shim, the sliding plates should have

at least 5 mm wearing surface remaining, if this is not the

case, they should be replaced.

Inserting shims for the upper sliding plate in the

attachment mounting

See the “Carriage sliding plates” illustration.

1. Shim 5 has a fixing slot, making attachment removal unnec-

essary when inserting additional shims.

2. Remove holding plate 6.

3. Loosen the sliding plate fixing screws so that the sliding plate

loosens from the carriage.

4. Slide in the required shim to adjust/remove the gap between

attachment and carriage.

5. Replace the holding plate and secure the sliding plate in

place.

Bleeding the lift cylinders

1. Use a hydraulic lift or similar.

2. When the mast is fitted, raise the inner mast approx. 0.3 m.

3. Connect a tube to each of the bleed nipples at the top of

each cylinder to collect any spill fluid, in a suitable container.

4. Open the bleed nipples on each of the lift cylinders, until all

air has been evacuated.

5. Re-tighten the bleed nipples.

Stretching of hoses

1. After a certain amount of use, the hoses will become

stretched and will therefore need to be tightened.

2. Stretch the hoses by loosening the hose holder from the car-

riage and move them down to a suitable new hole profile on

the carriage. See the “High-Lift Mast” illustration.

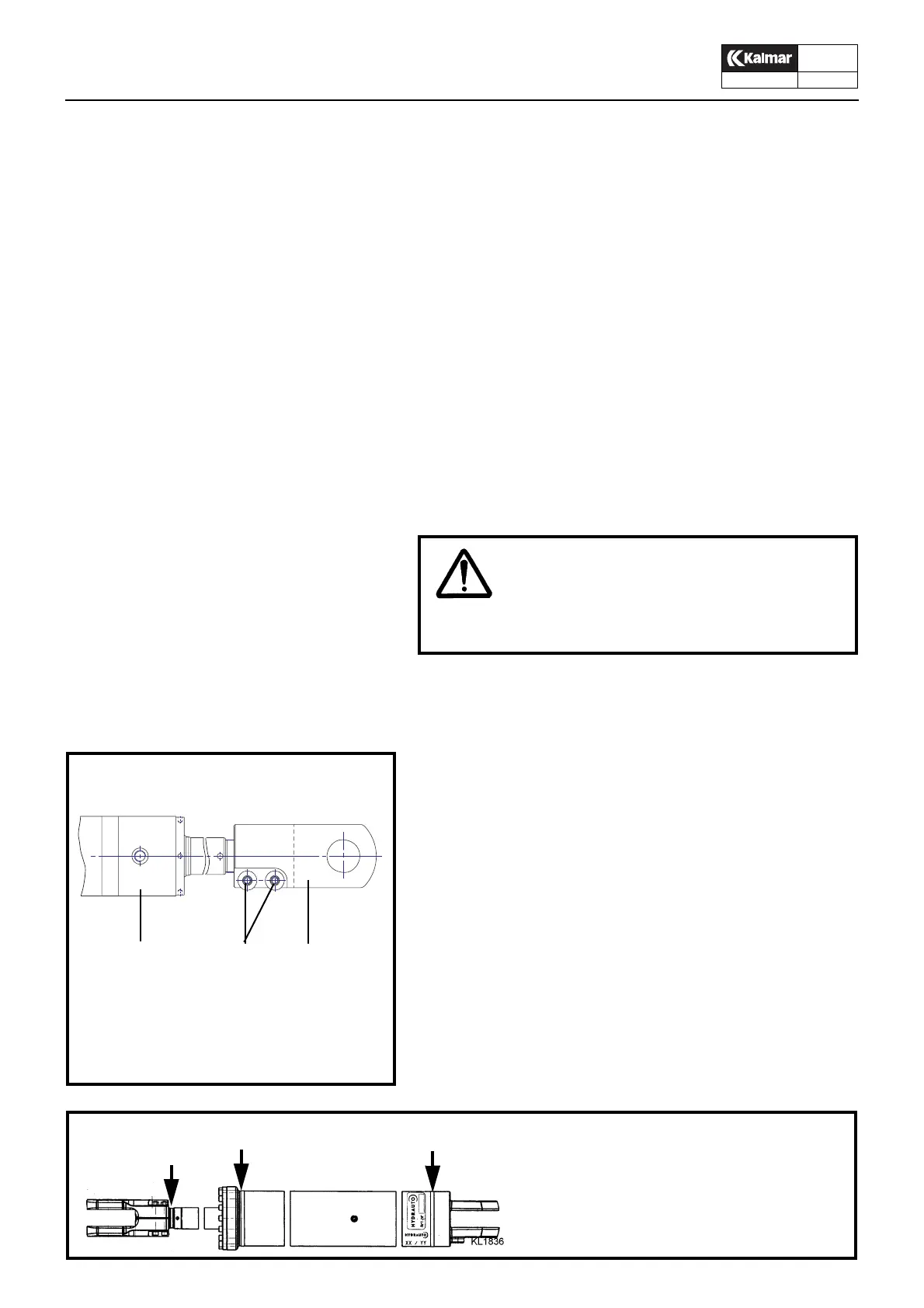

Tilt cylinder mounting, tightening torque

1. After any adjustment of the tilt angle, the piston rod head’s

mounting bolt should be tightened to a torque of 136 Nm.

See adjacent illustration.

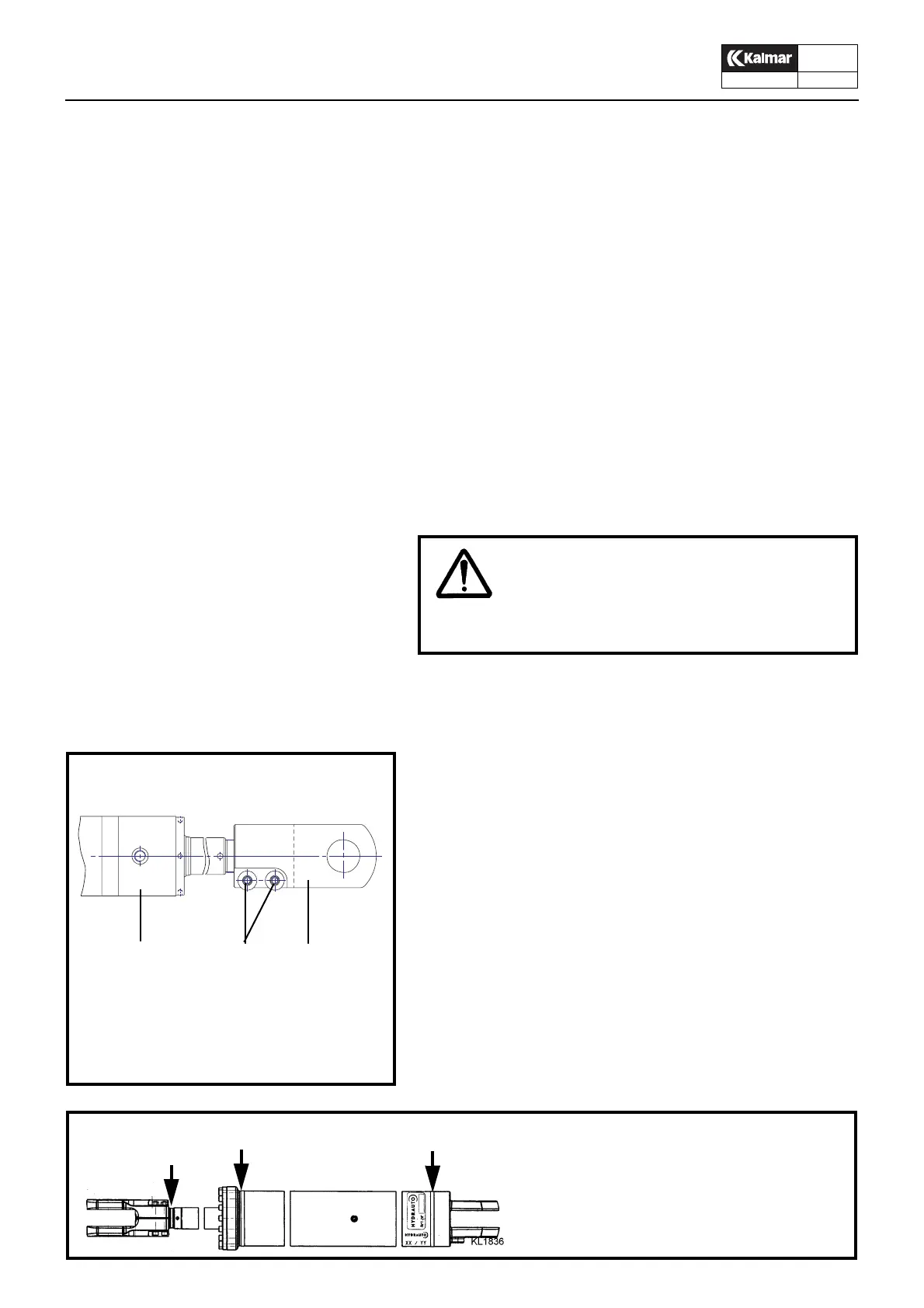

Checking tilt cylinders

The tilt cylinders should be checked every 500 hours considering

på cracks and also tightening torque as stated above.

4. Check to make sure that no cracks occur at welds and fillets.

Pay special attention to the items in the illustration below.

WARNING!

Risk for injury!

During the bleeding of the cylinders the inner mast and

carriage will lower. Ensure that nobody is in the way!

KL1127

1

2

3

1. Tilt cylinder

2. Mounting bolts

3. Piston rod head

Risk of crack formation

1. Thread exit

2. Weld

3. Weld

1

2

3

Loading...

Loading...