DCE80-100E

Technical Handbook

Brake system

Service

25

P.Group 70

TDCE01

04GB

Checking the brake system

The figures in the following text refer to the Hydraulic circuit dia-

gram. See also Checking the pressures and settings, group 70

page 10

The checks are to be made with the hydraulic system at the work-

ing temperature.

1. Start the engine.

2. Bleed the brake lines

– press the brake pedal

– open carefully the bleed nipple located on the inside of

one of the hubs until oil free of any air starts to flow from

the bleed nipple. tighten the nipple

– repeat the procedure for the other hub.

3. Connect a manometer to the test outlet (10) on the main

valve.

4. Allow the engine to run to full charging pressure as stated on

the hydraulic plate.

See also section Checking of pressures and settings Grupp

70 page 16 - 17.

5. Stop the engine and depress the brake pedal fully. The pres-

sure reading in test outlet 52 should be according to the hy-

draulic plate.

6. Release the brake pedal and check that the pressure falls to

0.

7. Check to make sure that there is enough charge in the accu-

mulator to cover at least eight brakings.

8. Check the clutch activating pressure

– Parking brake OFF

– Gear selector in F or R

– Depress the clutch pedal and listen for a clicking sound in

the electrical central unit in the cab.

At the clicking sound, e.g. the clutch being activated, the

pressure reading in outlet 52 should be 30±2 bar.

9. Check the activating pressure for warning lamp LOW

BRAKE PRESSURE

– Connect the manometer to test outlet 10 on the main

valve.

– Charge up the accumulator fully.

– Stop the engine, leave ignition key ON and depress the

brake pedal repeadetly.

– The warning lamp LOW BRAKE PRESSURE shoul light

up at 110-115 bar.

10. Check the accumulator’s pre-charging pressure as follows –

it should be according to the hydraulic plate.

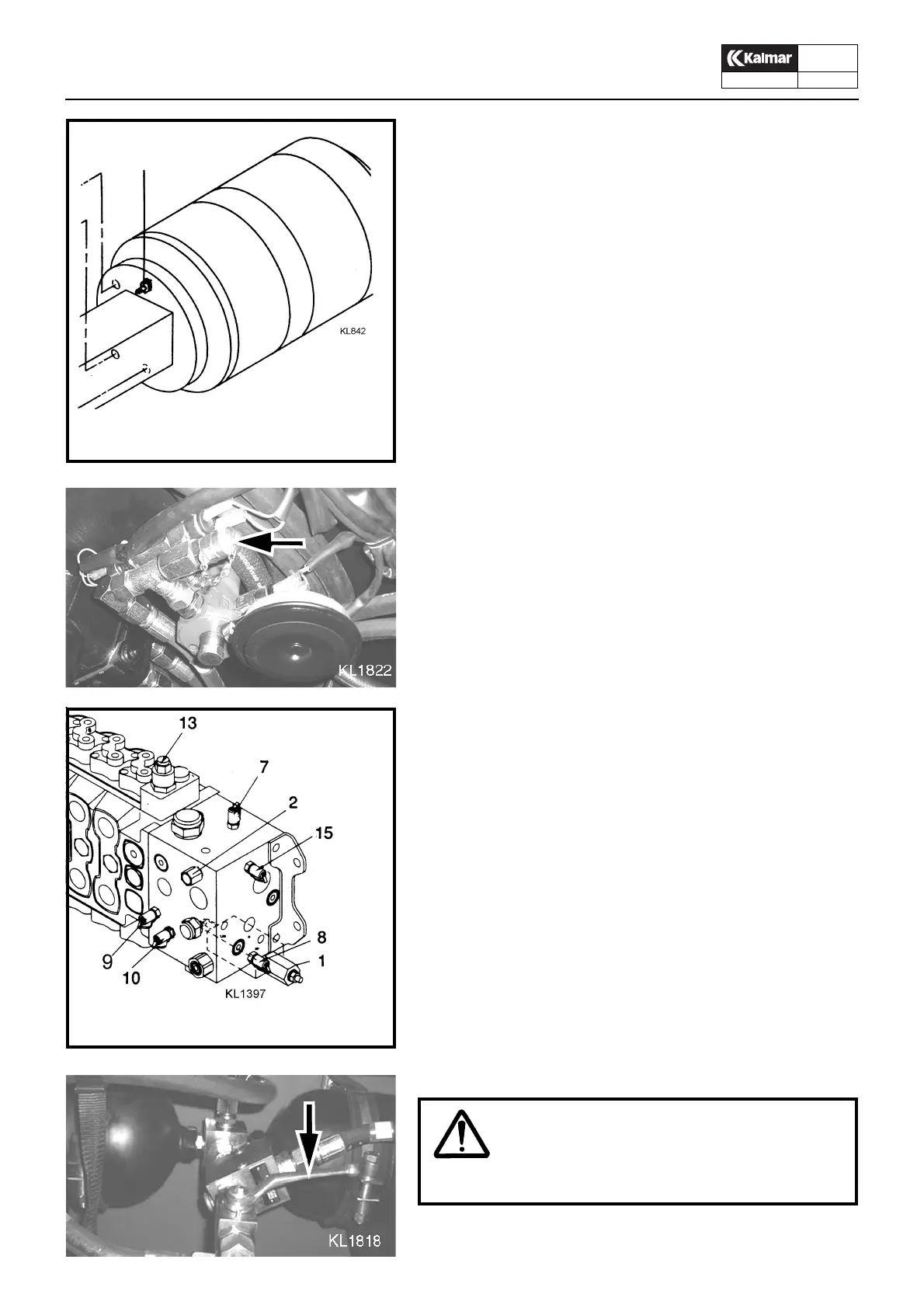

11. Open, carefully. the accumulator evacuating valve (42) ,

keeping a check on the manometer in the test outlet (10). At

the specified pre-charging pressure, the pressure should

drop sharply to 0.

12. If the pressure is lower, the pre-charging pressure should be

raised to the correct level using special filling equipment for

nitrogen gas accumulators.

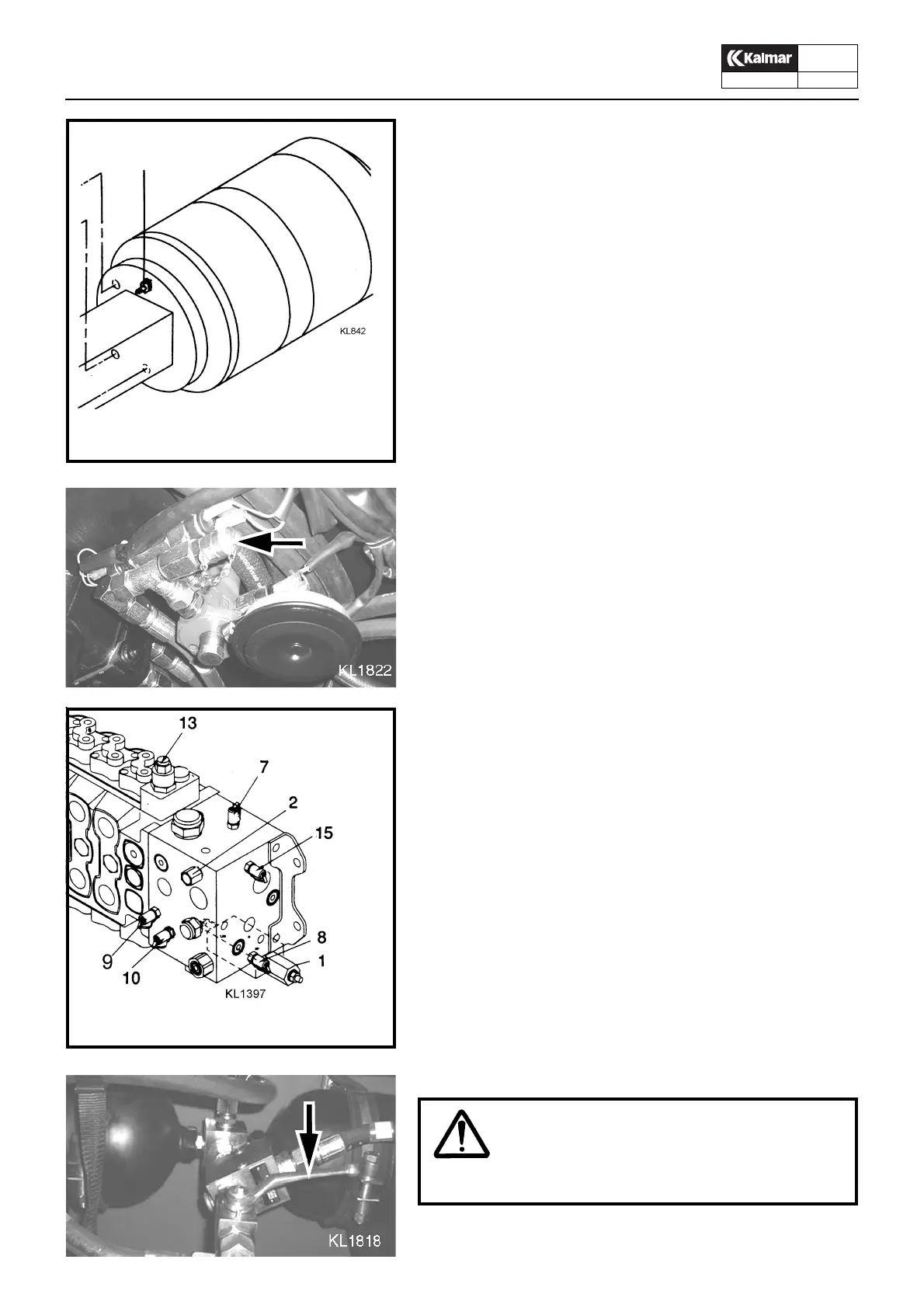

42 Accumulator evacuating valve

1

1. Bleed nippel

52

42

WARNING!

The charging equipment may be handled only by specially

trained personnel.

Loading...

Loading...