DCE80-100E

Technical Handbook

Main hydraulics

Service

15

P.Group 70

TDCE01

04GB

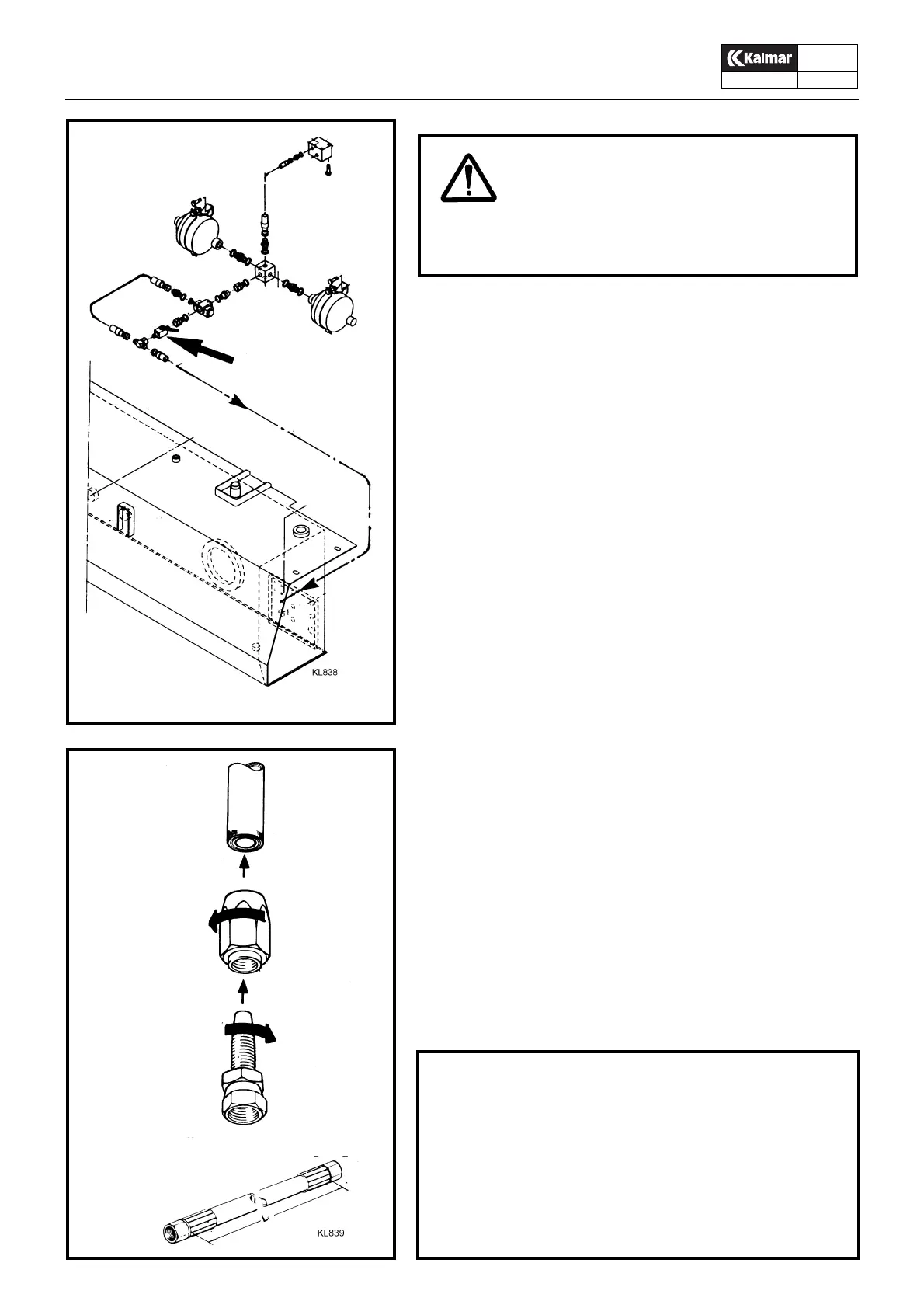

Take great care during all work on the hydraulic system. Avoid

being close to pressurized hydraulic components and hoses.

Observe strict cleanliness, since the presence of foreign matter

can easily result in a valve seizing or in other operational distur-

bances.

Checking the hydraulic hoses

Check hydraulic hoses and connections for leakage, cracking

and wear. Replace hoses if there is the slightest indication of

weakness. Tighten the connections as required.

Breather filter

The hydraulic reservoir is fitted with a breather filter which pre-

vents airborne impurities from entering the reservoir. Change the

filter as specified in the lubrication chart. The filter is of the spin-

on type. To change the filter, remove the old filter element, dis-

card it and screw on a new element.

Changing the hydraulic fluid

Change the hydraulic fluid in accordance with the lubrication

chart.

1. Remove the bottom plug of the hydraulic reservoir and drain

off the fluid.

2. Refit the plug and fill the reservoir with fresh hydraulic fluid.

The capacity is given in the Technical Specification.

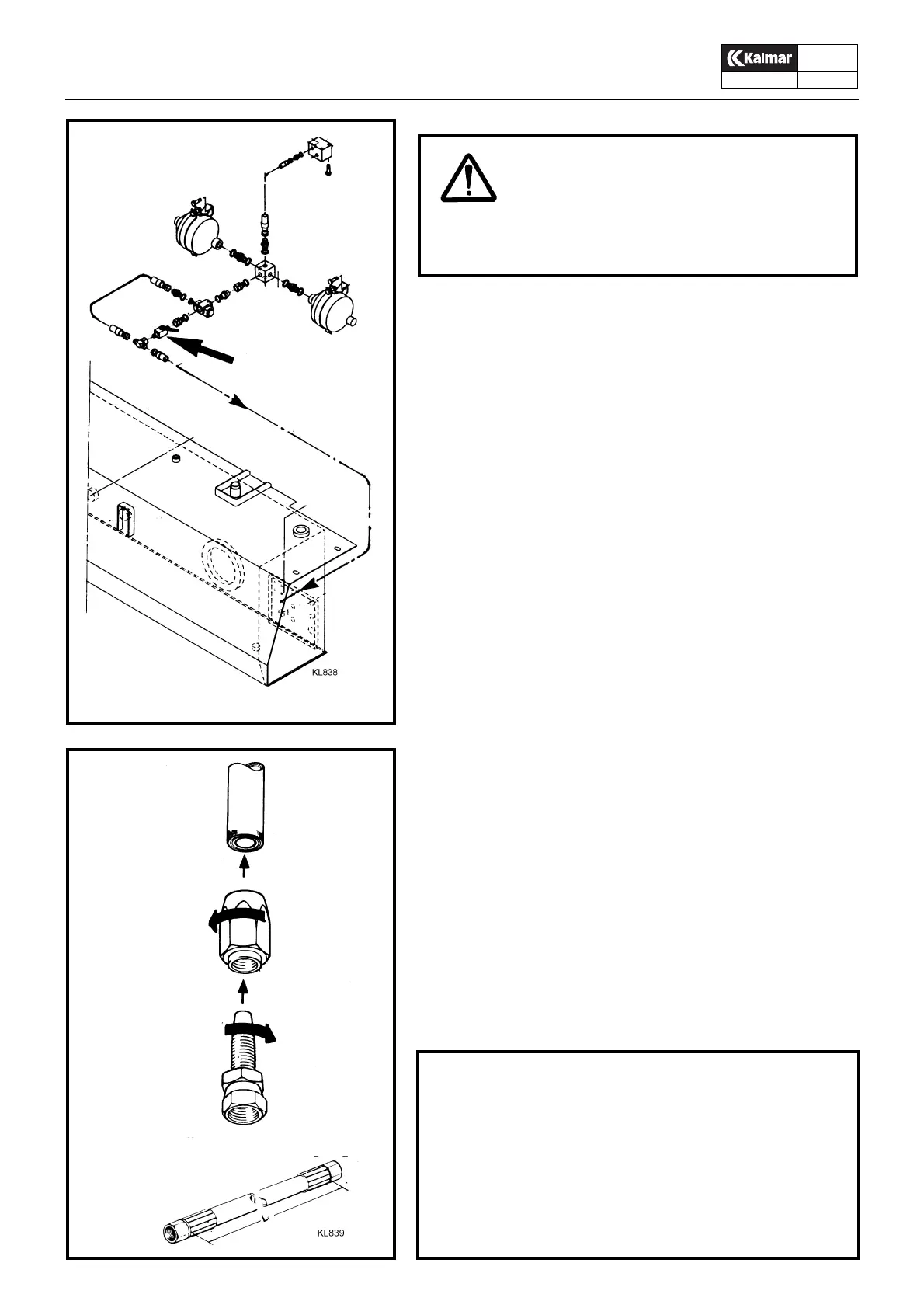

Mounting of fittings on hydraulic hoses.

1. Measure the length of the hose to be replaced.

2. Thread the sleeve ANTICLOCKWISE onto the end of the

hose until the hose bottoms in the sleeve. The sleeve has an

internal thread which will thus be pressed into the hose.

3. Grease the adapter thread and screw in the adapter

CLOCKWISE until it bottoms on the sleeve. The hose will

thus be clamped between the threads of the sleeve and

adapter.

4. Carefully flush the hose with white spirit, or equivalent, and

blow compressed air through it, so that the hose is absolutely

clean.

WARNING!

The hydraulic system includes a high-pressure accumu-

lator. Open the accumulator evacuating valve 42to re-

lease pressure before working on the hydraulic system.

42

42. Accumulator evacuating valve

1

2

3

4

1. Hose

2. Sleeve

3. Adapter

4. Measure the hose

length like this:

IMPORTANT!

The above procedure may be used only on 1" and smaller

diameter hoses. In addition, it may only be used on hoses

shown in the spare parts catalogue, with the sleeve and

adapter separated from the hose.

Hoses shown in the spare parts catalogue as complete

units with the end connections fitted must be ordered as

complete units in accordance with the catalogue.

Loading...

Loading...