DCE80-100E

Technical Handbook

Engine TAD720VE

Service

30

P.Group 30

TDCE01

04GB

Coolant quality

Throughout the year, the coolant should consist of a mixture of

60% of water and 40% of ethylene glycol. The coolant should be

changed and the cooling system should be flushed once a year.

Always add a corrosion inhibitor (Kalmar part No. 923.110.0003)

to the coolant, if the above mixture is not used in the cooling sys-

tem.

N.B. Never add a corrosion inhibitor if the cooling system

contains glycol, since this would cause foaming which seri-

ously impairs the cooling capacity.

Lubricating oil quality

See Group 90, Periodic supervision.

Draining the water from the fuel tank

Drain any water from the fuel tank by removing the drain plug. Im-

mediately refit the drain plug as soon as the flow of fuel is free

from water and other impurities.

Inspection of the air cleaner and changing the

filter element

Check the indicator when the engine is running orstopped. If it

shows red, the main filter element must be changed. The collect-

ing efficiency of the filter element will not be improved if the ele-

ment is changed too early. But if changing of the filter element is

delayed, smoke emission from the engine will increase, the en-

gine may lose power due to insufficient supply of combustion air,

and engine damage may occur in certain cases.

The air pipe from the air cleaner to the engine should be checked

for tightness from time to time. Minor leakage, such as that

caused by loose hose clips, and damaged or porous hoses may

cause dust to be drawn into the engine, which will give rise to

costly engine wear.

Change the filter element as follows:

1. The engine must not be running.

2. Clean the outside of the air cleaner.

3. Remove the cover.

4. Release and carefully remove the main filter element. Do not

remove the safety filter element. Fit a new main filter ele-

ment. Carefully check that it is not damaged. Note on the

safety filter element when the main element was replaced.

5. Reset the filter indicator.

6. Change the safety filter element:

– after the main filter element has been changed five times

– at least every other year

– if the indicator shows red after the main element has been

changed

– if the engine has been run with the main element dam-

aged

The safety filter element must not be cleaned and reused. The

engine must not be run without the main filter element. If the main

element must be cleaned and refitted in emergency cases, don’t

use compressed air to clean it, since the filter element may be

damaged. Before refitting it, carefully check that the main filter el-

ement is undamaged.

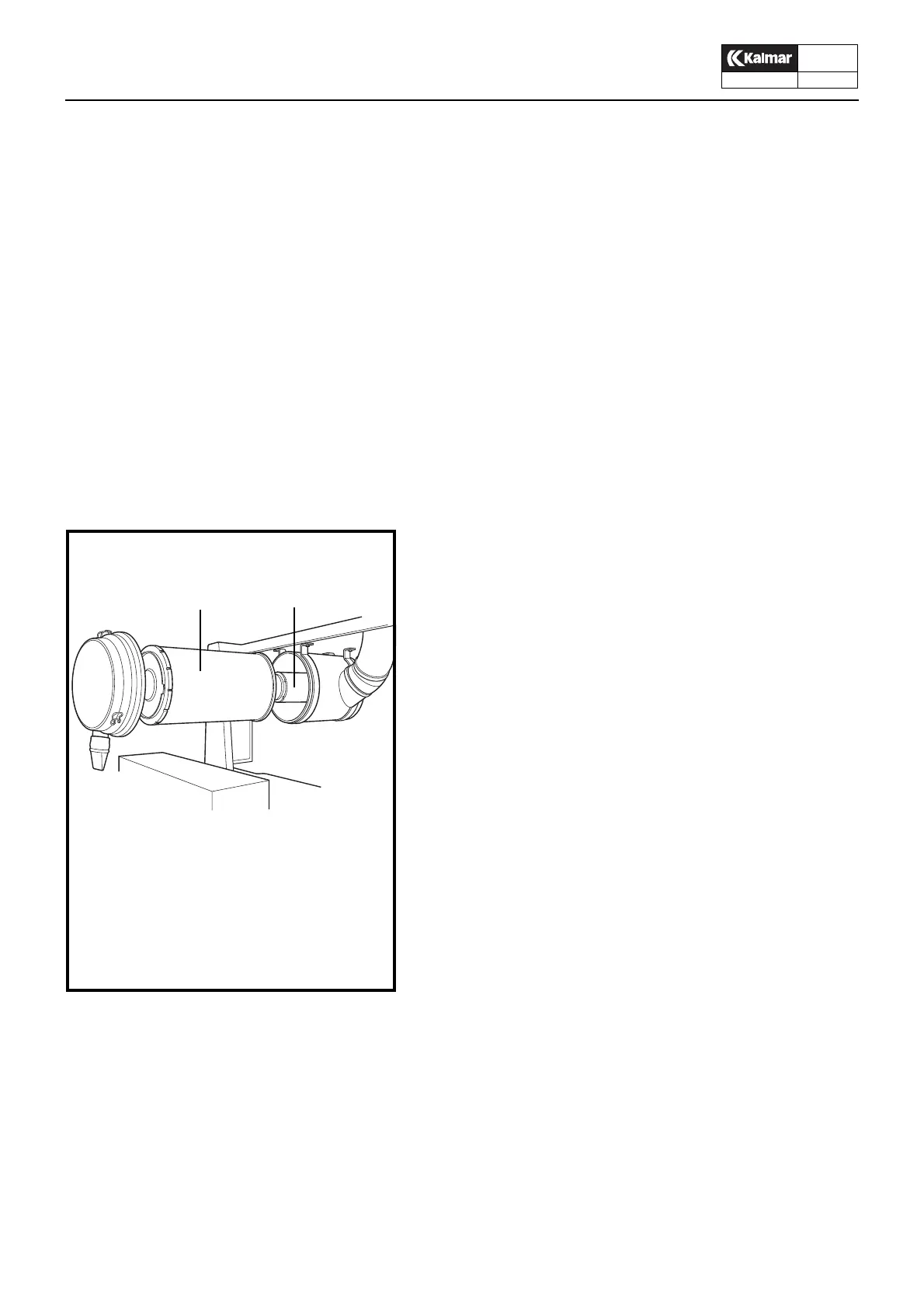

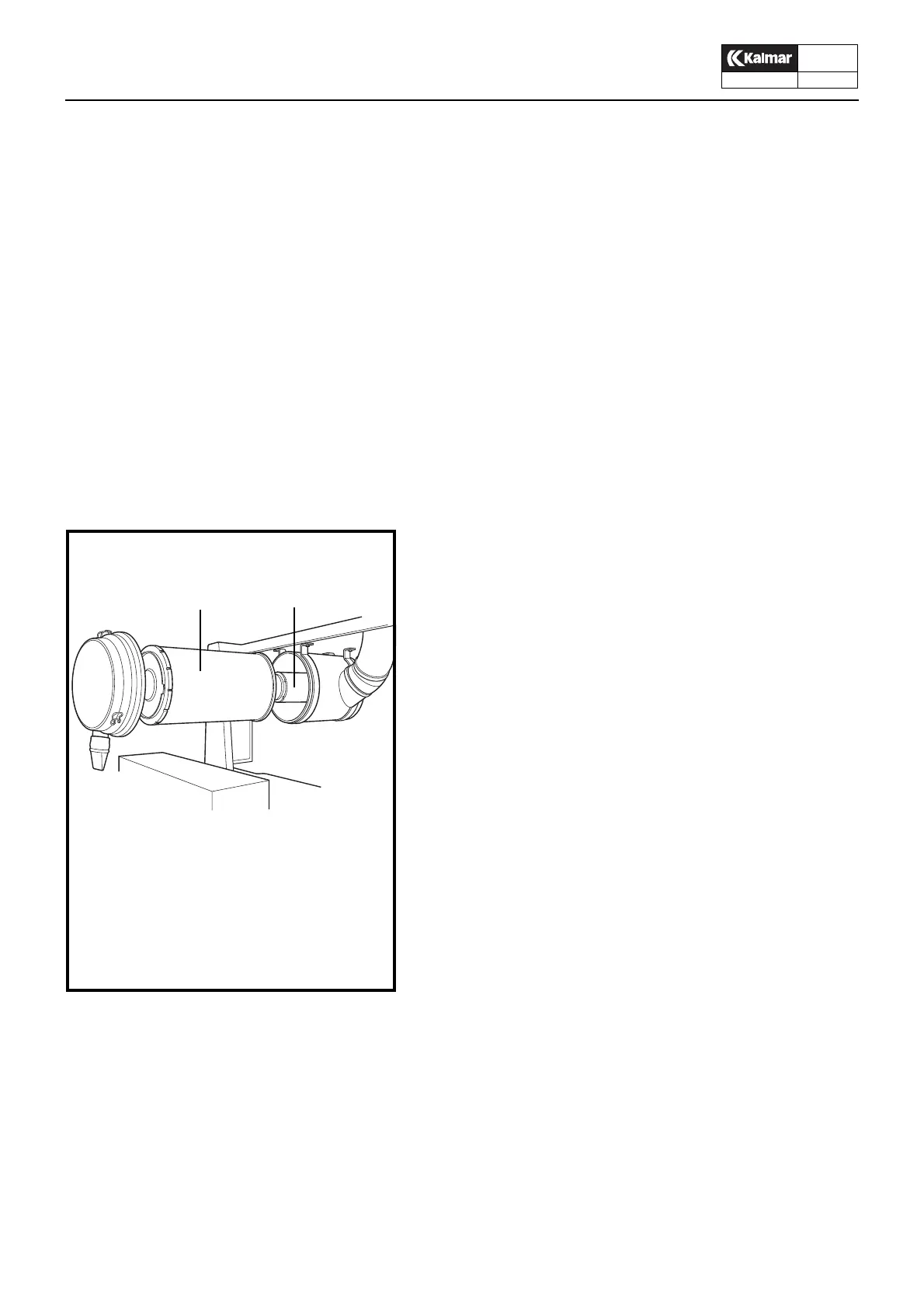

1. Main filter element

2. Safety filter element

KL1637

1

2

Loading...

Loading...