DCE80-100E

Technical Handbook

Main hydraulics

Service

17

P.Group 70

TDCE01

04GB

Checking of pressures and settings,

system with separate side-lift hydraulics

1. When making the following tests, use a manometer with a

hose of suficcient length so as the reading can be made from

inside the operator’s cab.

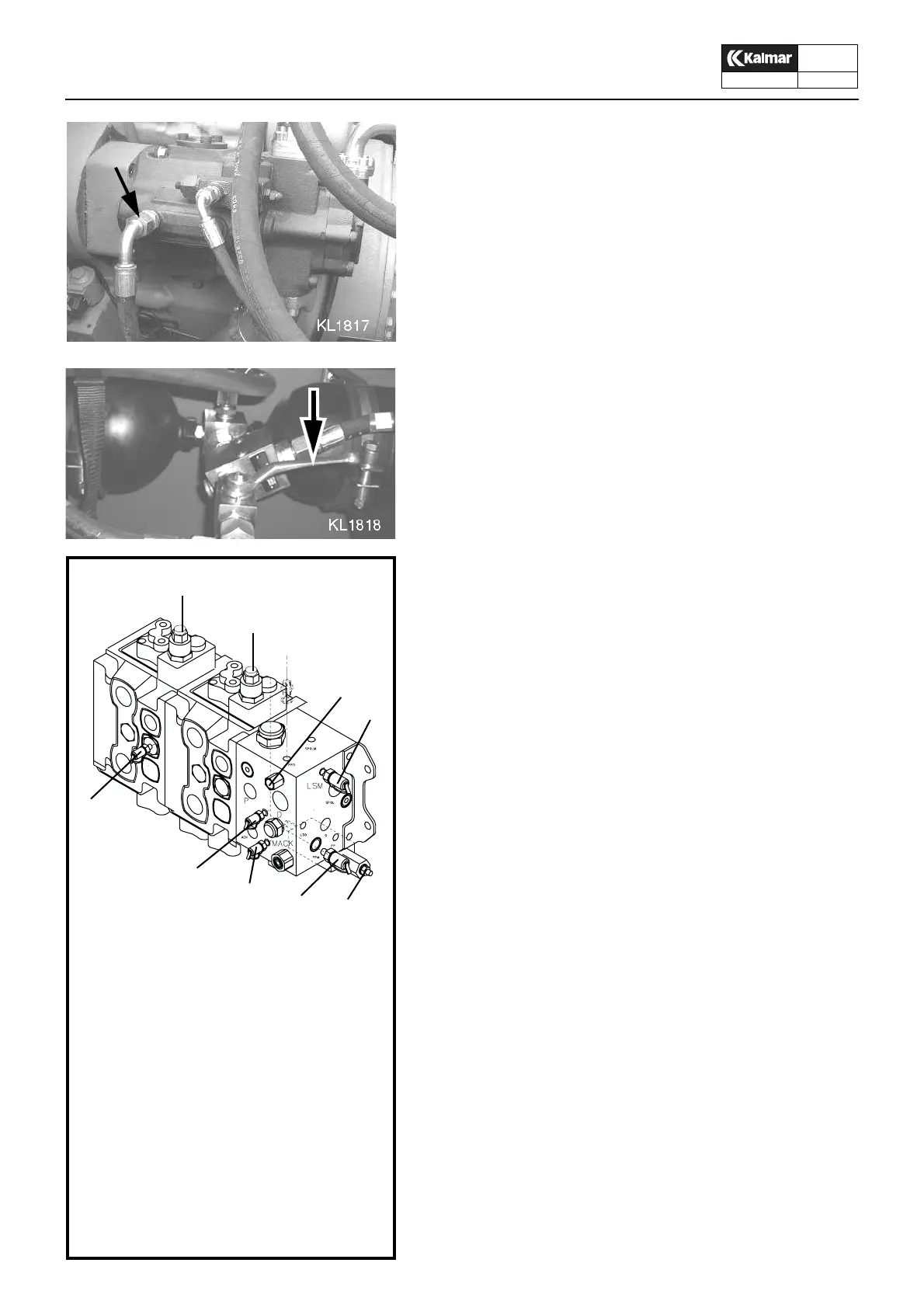

2. Unscrew the connection at A on the variable pump and fill the

pump with hydraulic oil. Reconnect A.

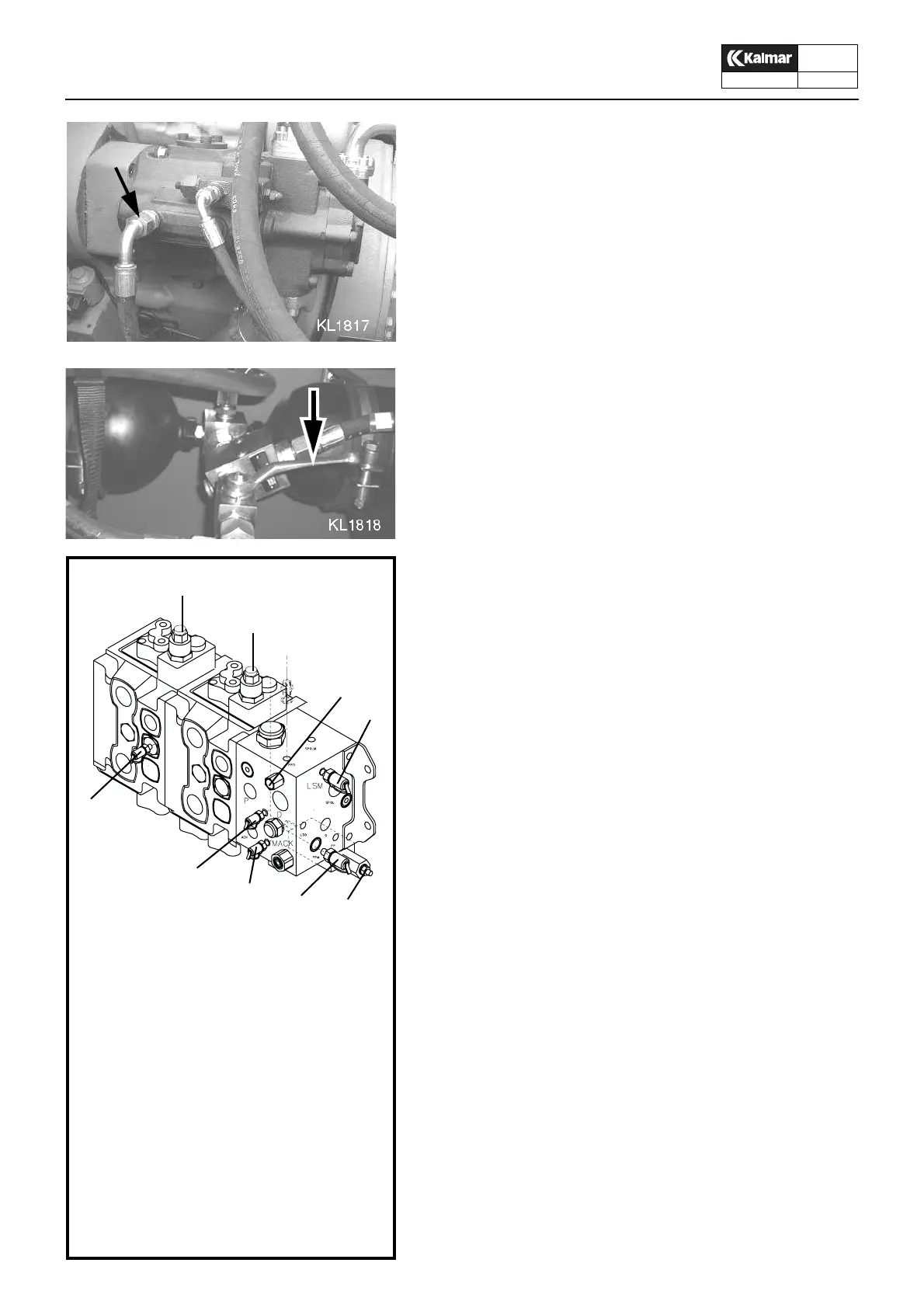

3. Open the accumulator evacuating valve 42 and start the en-

gine.

4. Stop the engine to check that the stopping device is working.

Pressure, accumulator charging

5. Connect the manometer to test outlet 10.

6. Start the engine and let it run at 1200 r/min.

7. Close the accumulator charging valve 42.

8. The pressure in 10 should increase from the accumulator

pre.charging pressure up to the charging pressure according

to the hydraulic plate. Adjust if necessary on adjustment

screw 1.

Pressure Steering system

9. Stop the engine and slightly lift up the machine to relieve the

steering wheels.

10.Connect th manometer to test outlet 15.

11.Start the engine and let it run at 1200 r/min

12.Check the steering pressure in test outlet 15. Turn the stee-

ring wheel in one direction. Let the steering spindle go to stop

and read the pressure. The pressure reading should be accor-

ding to the hydraulic plate. Adjust if necessary on adjustment

screw 2.

Pressure servo system

13.Connect the manometer to test outlet 8. The pressure reading

should be 35±5 bar. Tis pressure cannot be adjusted.

Pressure working hydraulics, TILT and LIFT

14.Connect the manometer to test outlet 9. Operate the tilt func-

tion until stop and read the manometer. The pressure reading

should be according to the hydraulic plate. The pressure

reading should also be equal to the pressure in outlet 14, see

next item. Justera vid behov på justerskruv 13.

15.Connect the manometer to test outlet 14. The pressure is set

individually for each truck and is stated in the delivery specifi-

cation and the hydraulic plate. The pressure should be set so

that the truck can only just lift its rated load at the appropriate

load centre. The pressure should be equal to the pressure in

outlet 9. Adjust if necessary on adjustment screw 12.

16.The adjusting screw must be sealed after making any adjust-

ment.

..to be continued next page.

A

42

KL1834

12

13

2

14

9

10

8 1

15

(Numreringen gemensam med Hydraulschema

A44866.0100)

1 Justerskruv, ackumulatorladdningstryck

2. Justerskruv, tryck i styrsystem

8 Mätuttag servotryck 35±5 bar, ej justerbart

9 Mätuttag, TILT

Skall ha samma tryck som 14

10 Mätuttag, ackumulatorladdning

12 Justerskruv, huvudtryckbegränsnings-

ventil LYFT. Ställs lika med 13

13 Justerskruv, huvudtryckbegränsnings-

ventil TILT. Ställs lika med 12

14 Mätuttag, LYFT

Skall ha samma tryck som 9

Mät- och justeringspunkter,

ventilblock och huvudventil

Loading...

Loading...