DCE80-100E

Technical Handbook

Steering axle

Service

9

P.Group 60

TDCE01

04GB

Inspection procedure

1. Dismantle the rim according to the standard procedures, see

also Safety instructions when working with tyres, group 00.

2. Carefully clean the outside of the rim beadrim bead by using

a wire brush.

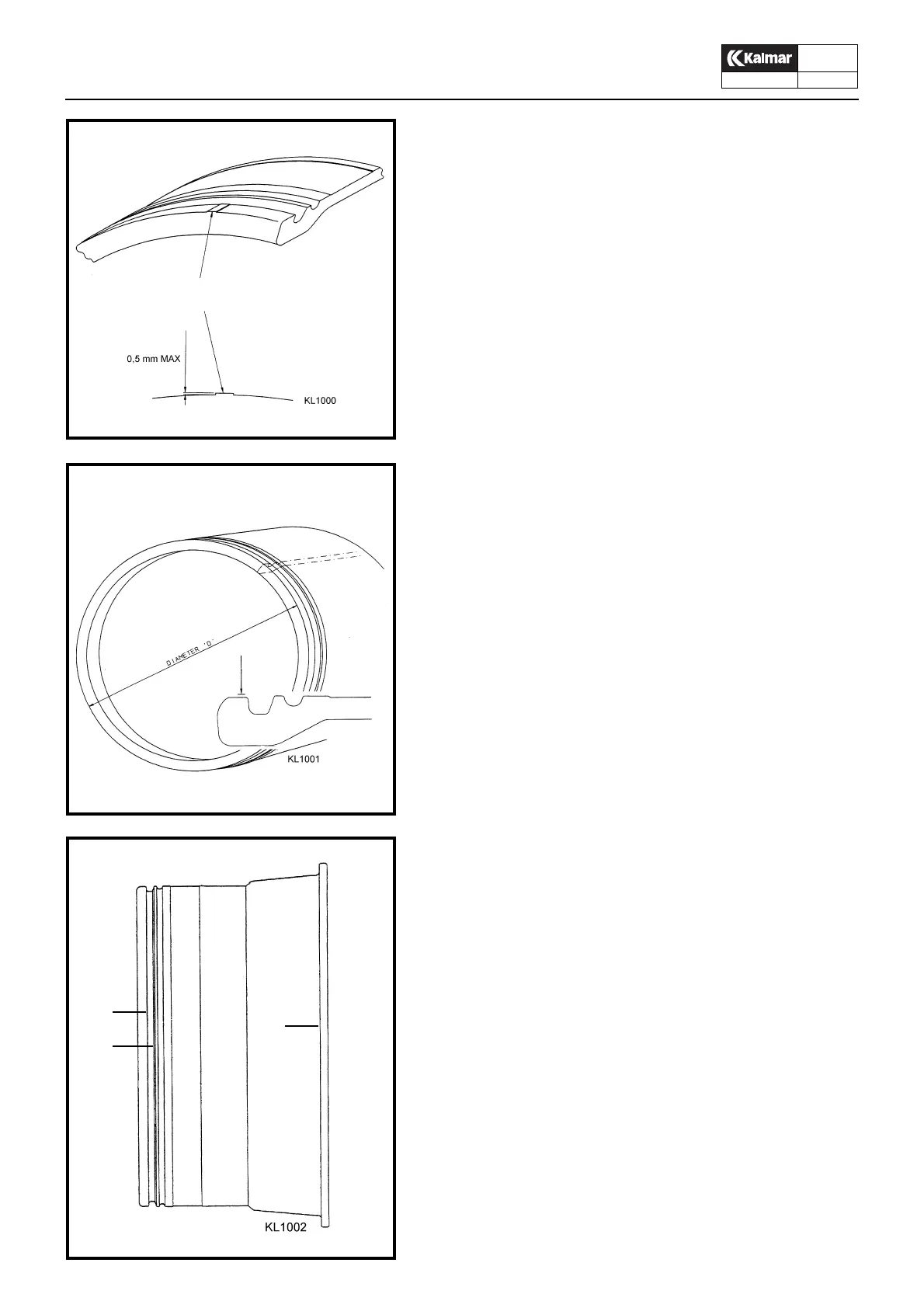

3. The wear of the lock ring on the rim bead outside diameter

can produce a mark A. The mark is located between the

ends of the lock ring, see picture.

4. Measure the depth of the wear at this point using av straight

edge and feeler gauge. If the wear exceeds 0,5 mm, the

wheel, the lock ring, and the beadseat or loose flange must

be discarded and replaced with new.

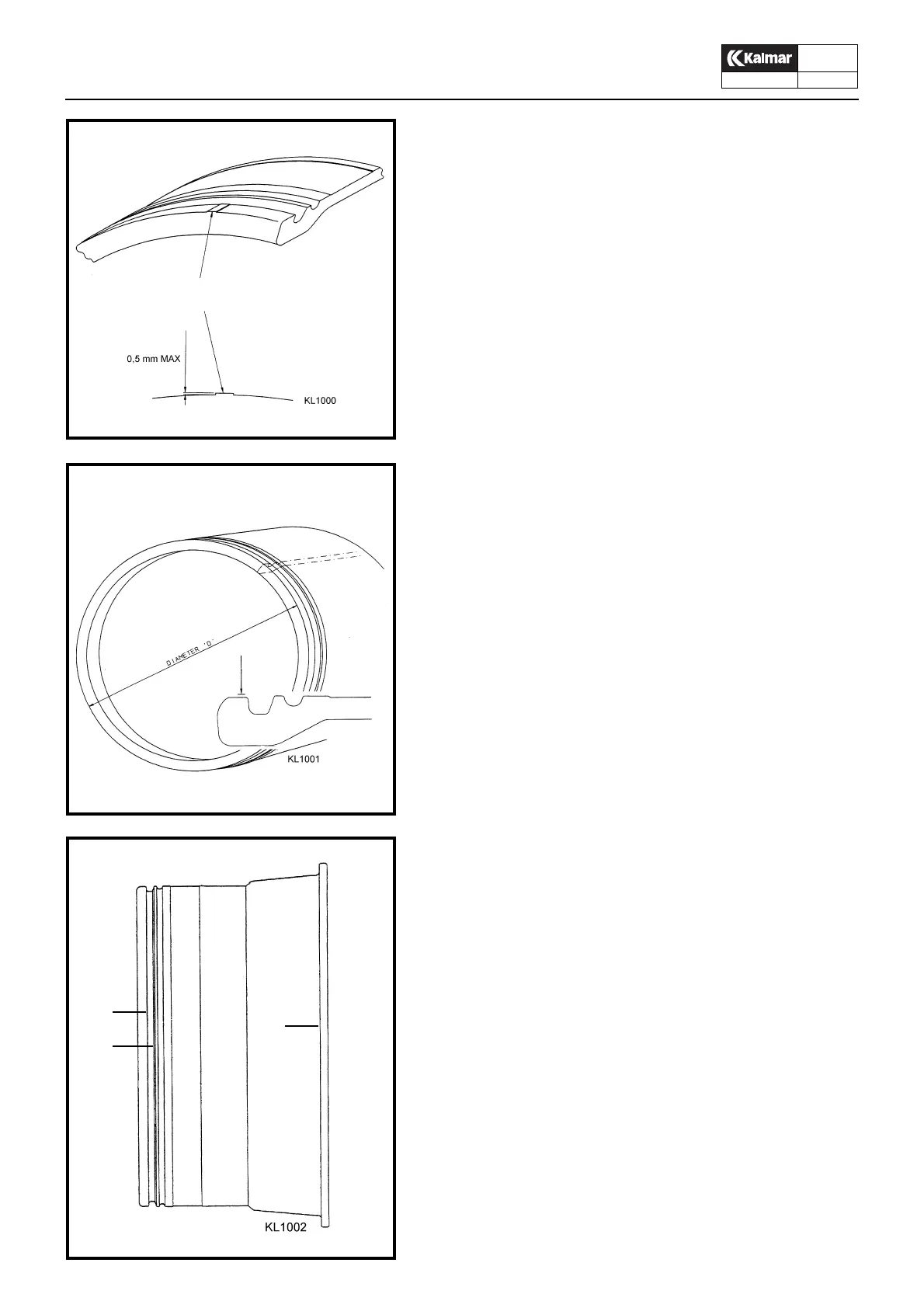

5. If a wear mark is not possible to find, measure the circumfer-

ence of the rim bead using a measuring tape.

6. Calculate the diameter D = Circumference/3.14

7. If the diameter is below the minimum specified, the wheel,

the lock ring and the beadseat or loose flange must be dis-

carded.

Information on the minimum diameter of your rim bead can

be recieved from Kalmar LMV.

High stress areas, how to identify rim damage

1. High stress areas are marked with B on the illustration

2. Typical faults are: circumferential cracks, fretting, corrosion

pitting, distortion, wear.

3. Inspect above areas at each tyre change

A

D

D

B

B

B

Loading...

Loading...