DCE80-100E

Technical Handbook

Periodic supervision

Lubrication

5

P.Group 90

TDCE01

04GB

1) The interval is greatly dependent on the fuel and lubricant

quality as well as the operating conditions.

If intervals longer than 200 hours are desired, the condition

of the oil must be checked by the company

making the oil, by means of regular lubricant tests.

For volumes, see Technical Data.

For lubricating oil grades, see Oil and lubricant recommenda-

tions

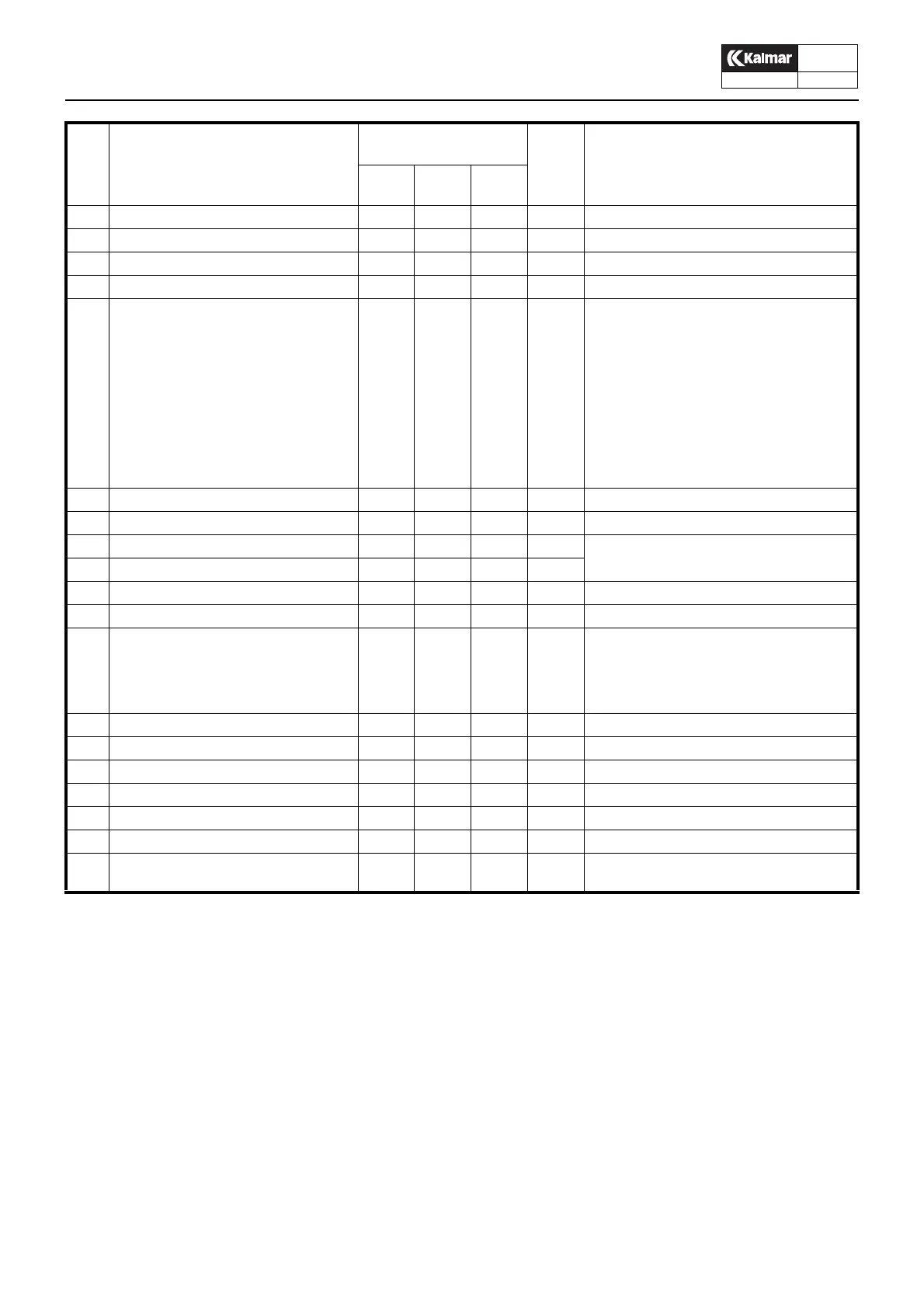

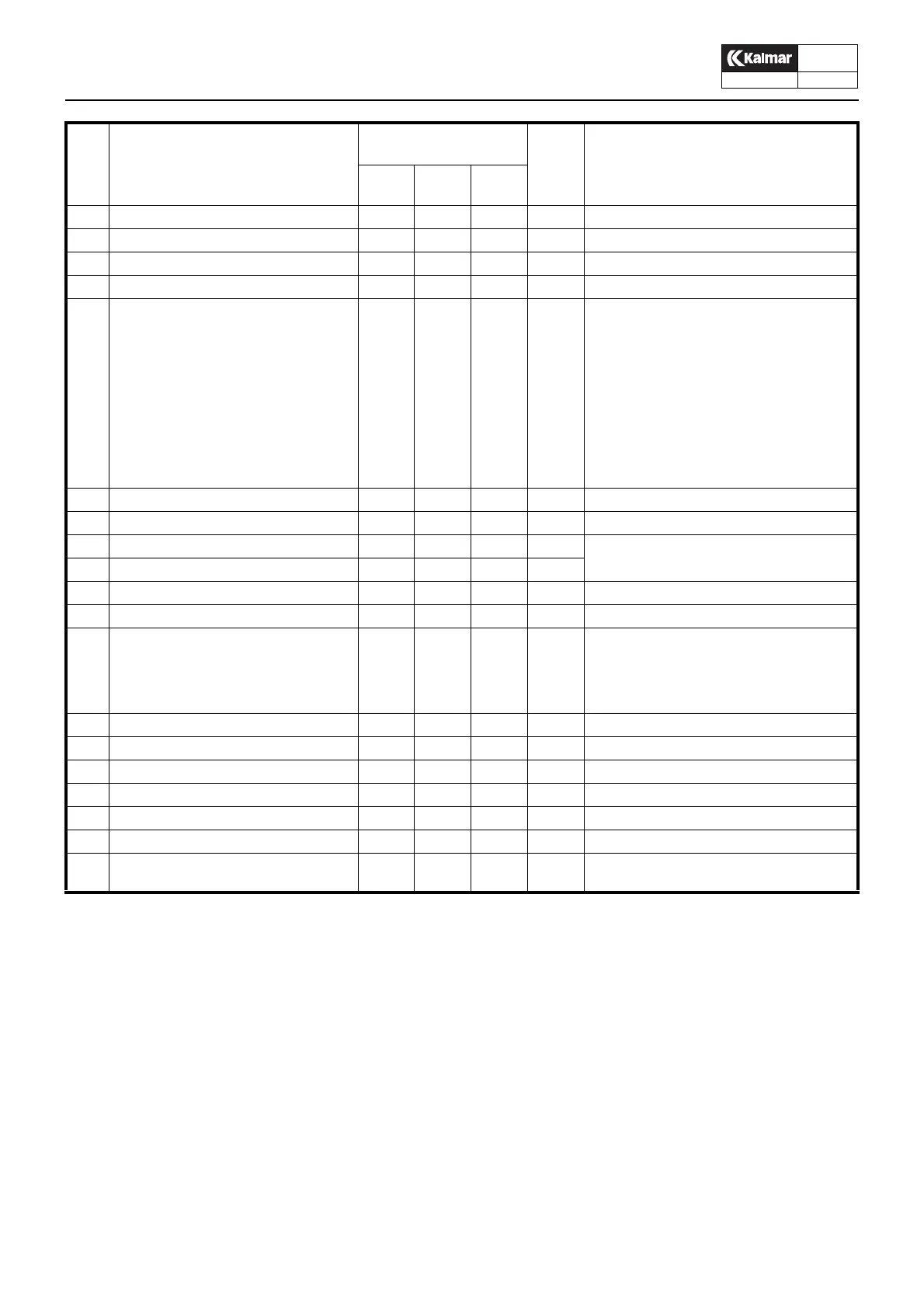

L=Lubricate

C=Check

Item

No.

Description Interval

operating hours

No. of

lub.

points

Remarks

200/

400

500 1000

1 Cylinder bearing, tilt cylinders L 4

2 Mast suspension L 2 Relieve the mast of load when lubricating

3 Cylinder bearing L 4

4 Support rollers, mast and carriage 18

5 Sliding plates outer - innermast

inneremast - carriage

carriage - sidelift

L

L

L

4

4

8

Use skylift or similar.

Lubricate all sliding surfaces with

lubricating agent. Use a brush and

distribute evenly.

Operate the mast to max lifting height.

Every 500 hours, check

bolted joints and

the wear of the sliding plates

. If the re-

maining thickness of any plate is less than

3 mm it must be replaced, see Technical

Handbook.

6 Engine oil x x) Oil change every 200 hours

1)

7 Oil filter, engine x 2 x) Filter change every 400 hours

8 Steered wheel bearings 2 Dismantle, clean, inspect and pack with

grease every 4000 hours

9 Knuckle pin bearing 4

10 Gearbox oil x 1 x) Oil change. Check level while idling

11 Gearbox, oil filter x 1 x) Filter change

12 Drive axle C x 3 x) Oil change, differential and hubs.

First oil change after 200 h, thereafter every

1000 h.

Drain the oil at working temperature

Check the levels after refill

13 Propeller shaft L 3

14 Hydraulic fluid filter x 2 x) Filter change

15 Hydraulic fluid 1 Oil change every 2000 hours

16 Breather filter, hydraulic reservoir x 1 x) Filter change

17 Linkage, steered axle L 4

18 Hinges, doors and hatches L Dismount doors and hatches

19 Brake pedals C L 2 Check and retighten the pedal axle locking

screws. Lubricate axle nipples

Loading...

Loading...