ULTRAFLOW®54(H)/(J)

KamstrupA/S∙TechnicalDescription∙5512‐1554_J1_GB_04.2018

23

7.2 Inlet requirements

ULTRAFLOW

®

requires neither straight inlet nor straight outlet to meet the Measuring Instruments Directive (MID)

2014/32/ EU, OIML R75:2002 and EN 1434:2015. A straight inlet section will only be necessary in case of heavy

flow disturbances before the sensor. It is recommended to follow the guidelines based on CEN CR 13582.

Optimal position can be obtained if you take the below-mentioned installation methods into consideration:

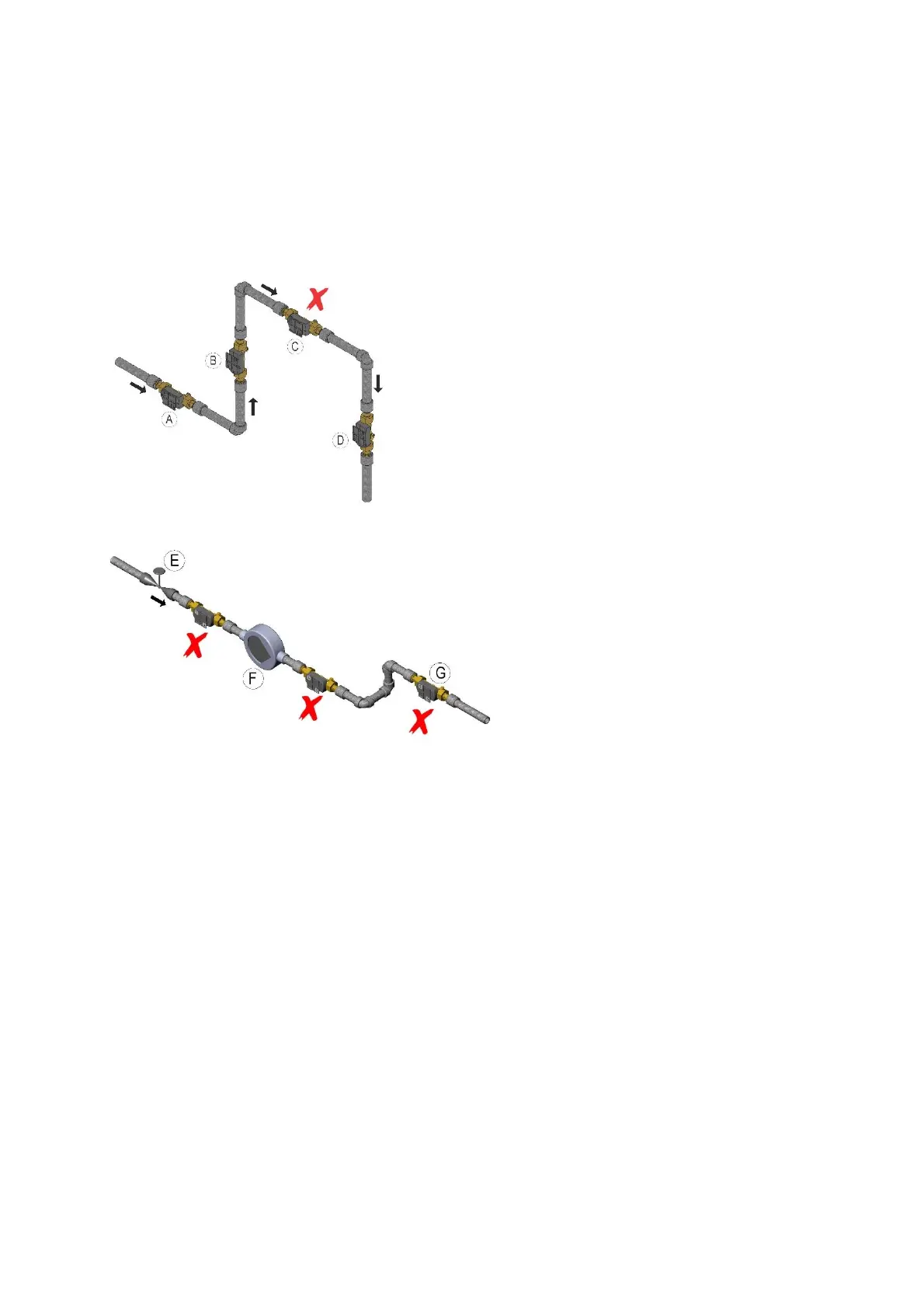

Figure 11

For general information on installation, see CEN report CEN/CR 13582, Heat meter installation. Instructions in

selection, installation and use of heat meters.

7.3 Operating pressure

In order to prevent cavitation the back pressure (the pressure at the flow meter outlet) at ULTRAFLOW

®

must be for

q

p

0.6…2.5 m

3

/h (q

p

≥ 3.5 m

3

/h) min. 1.0 bar (1.5 bar) at q

p

and min. 2.0 bar (2.5 bar) at q

s

. This applies to

temperatures up to approx. 80 °C. ULTRAFLOW

®

must not be exposed to pressure lower than the ambient pressure

(vacuum). For further information on operating pressure, see paragraph. 8.4 Guidelines for dimensioning

ULTRAFLOW

®

.

A Recommended flow sensor position.

B Recommended flow sensor position.

C Unacceptable position due to risk of air

build-up.

D Acceptable position in closed systems.

Unacceptable position in open

systems due to risk of air build-up in

the system.

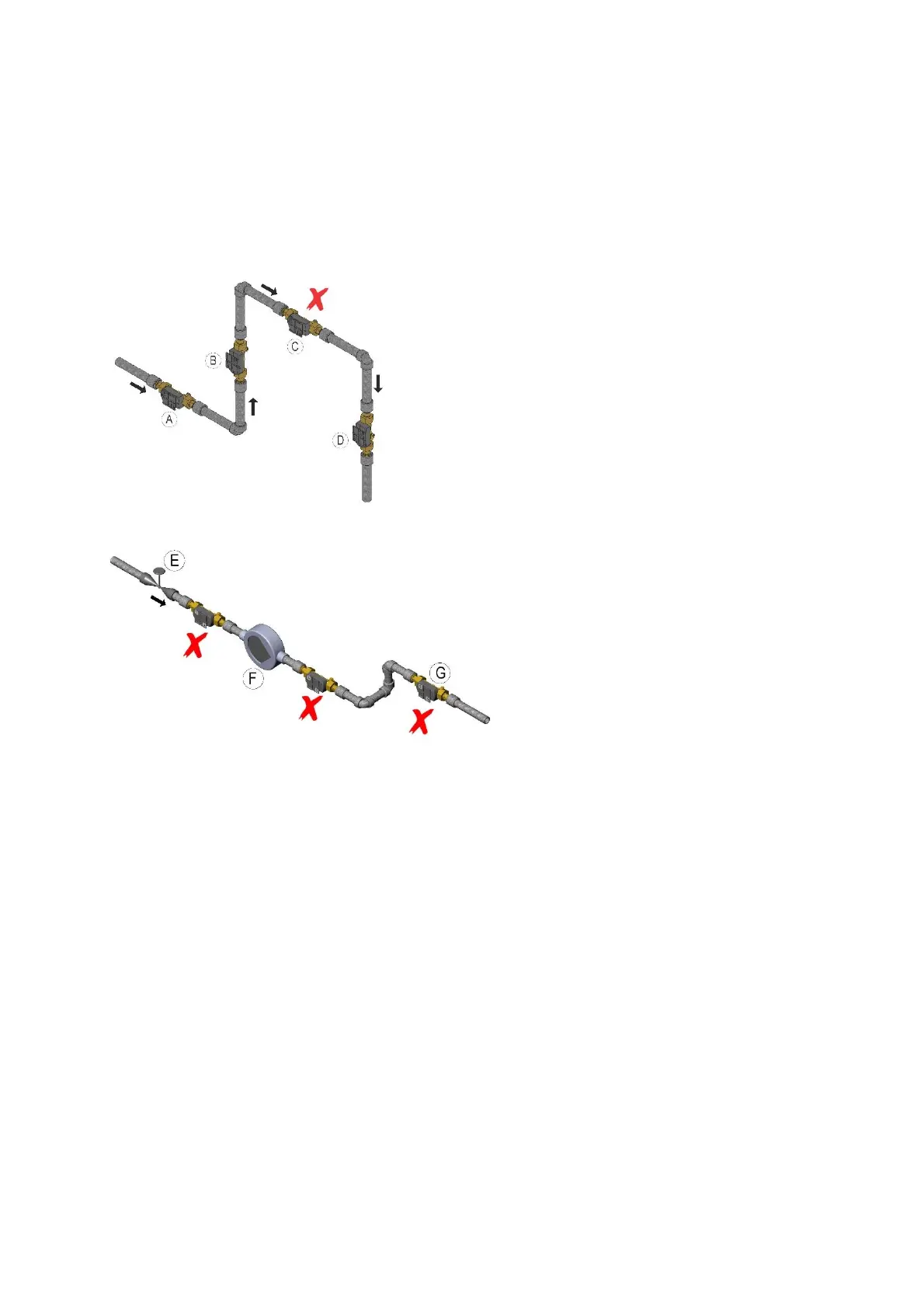

E A flow sensor ought not be placed

immediately after a valve, except for

block valves (ball valve type),

which must be fully open when not

used for blocking.

F A flow sensor ought not be placed

directly before (suction side) or

directly after (outlet side) a pump.

G A flow sensor ought not be placed

immediately after a double bend in two

levels.

Loading...

Loading...