On standard width systems, the minimum material width is 19.05 mm (0.75”) to allow

enough support for the adjustable guide rail positioning bars. On wide blade

systems, the minimum material width is 57.15 mm (2.25”). If the adjustable rail is

too close to the fixed rail, the positioning bars cannot be locked into position.

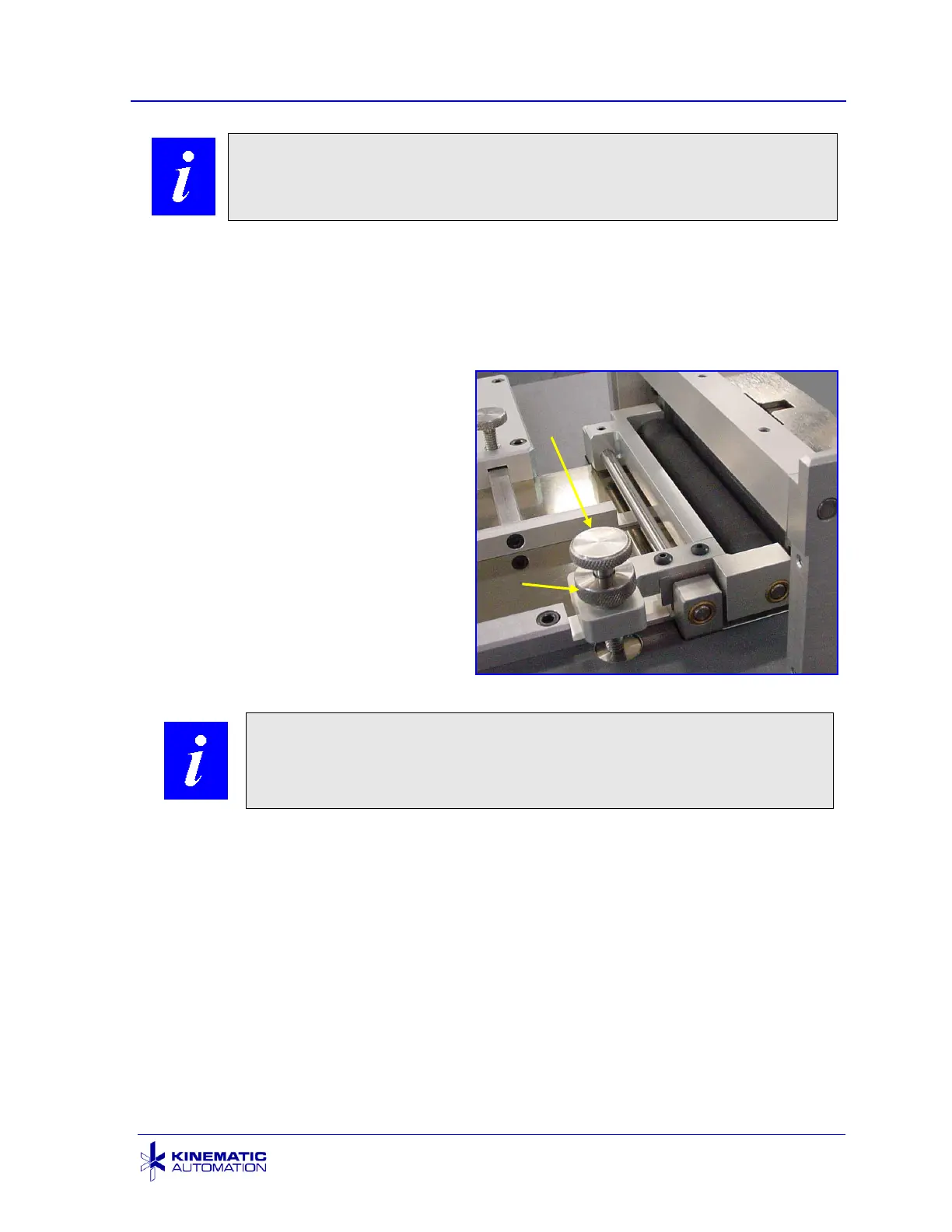

5.4.2 Roller Tension

Product is driven through the guillotine

blade by an indexing bottom drive

roller with an idler roller on top. The

indexing roller is fixed in place, while

the idler roller is spring loaded against

the indexing roller. (See Section

5.1.2.)

A Roller Tension Adjustment Knob is

provided to the left of the blade cover.

Hold down on this knob to temporarily

raise the idler roller and insert

material.

Roller Tension Adjustment Knob

NOTE: Maximum roller force is approximately 3.9 kg (8.5 lb).

However, the roller tension should be adjusted to no more than what

is required to hold the material securely; higher pressures will deform

the compliant roller and lead to strip width issues.

The pressure of the spring-controlled idler roller in the down position is adjustable,

and may be adjusted to accommodate the material used. Adjust the roller pressure

for your material by following these steps:

1. Shut off electrical power by unplugging the machine.

2. Open the clear blade cover over the rollers.

3. Press and hold the top of the Roller Tension Adjustment Knob down and

insert the material through the rollers.

4. Release the knob.

Loading...

Loading...