NOTE: While the die block is removed, there is much better

access to clean the pinch rollers. See the User Manual.

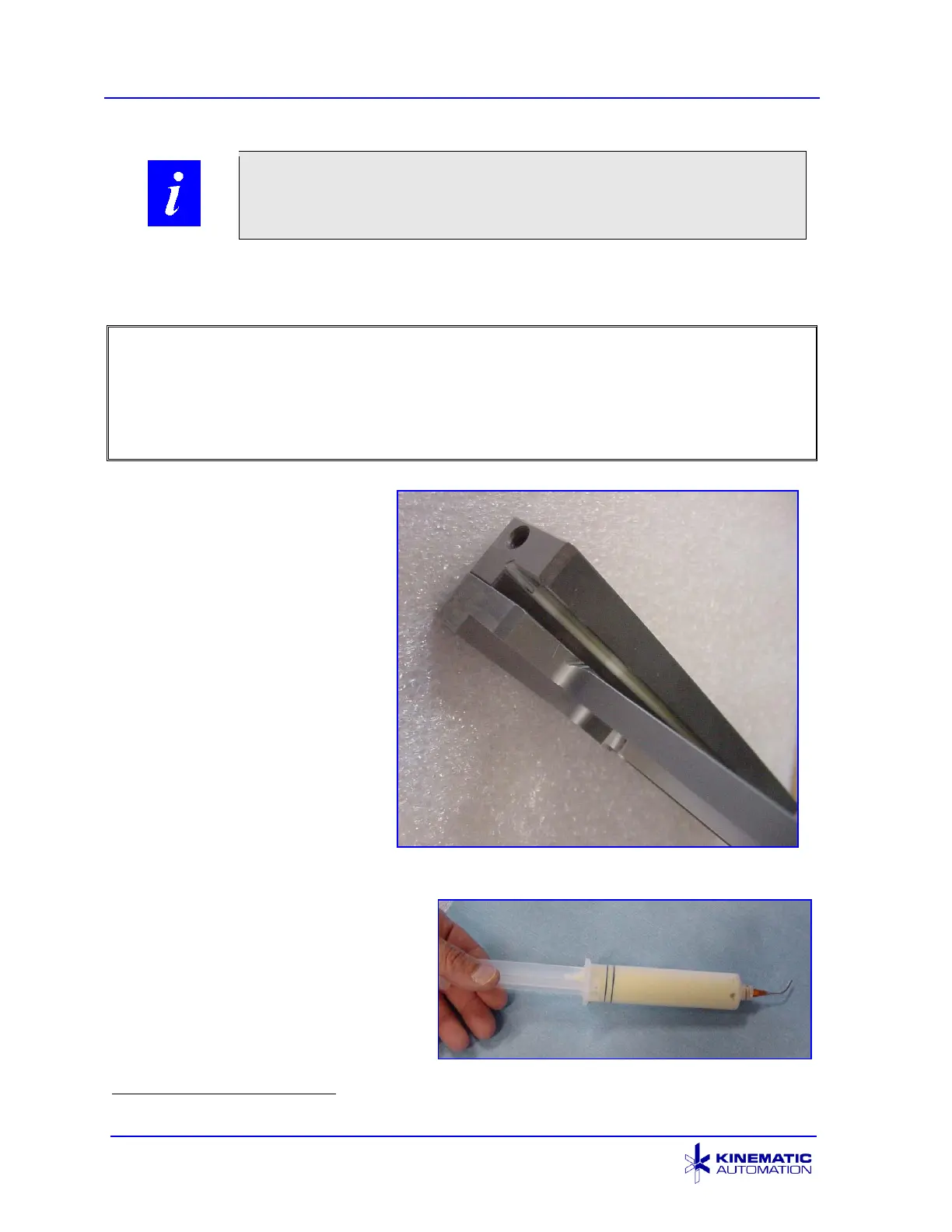

The inside of the blade guides

should be lightly lubricated on

all three sides where the guides

might contact the blade. The

grease may be applied by using

a long cotton tipped swab

coated with the grease.

There is also a groove on the

right and left side of the blade

guide area that must be filled

with grease. See the illustration

to identify the location of the

grooves. Only one side is

illustrated. The other side has a

similar groove. The illustration

shows a groove already filled

with grease to help make it easy

to see.

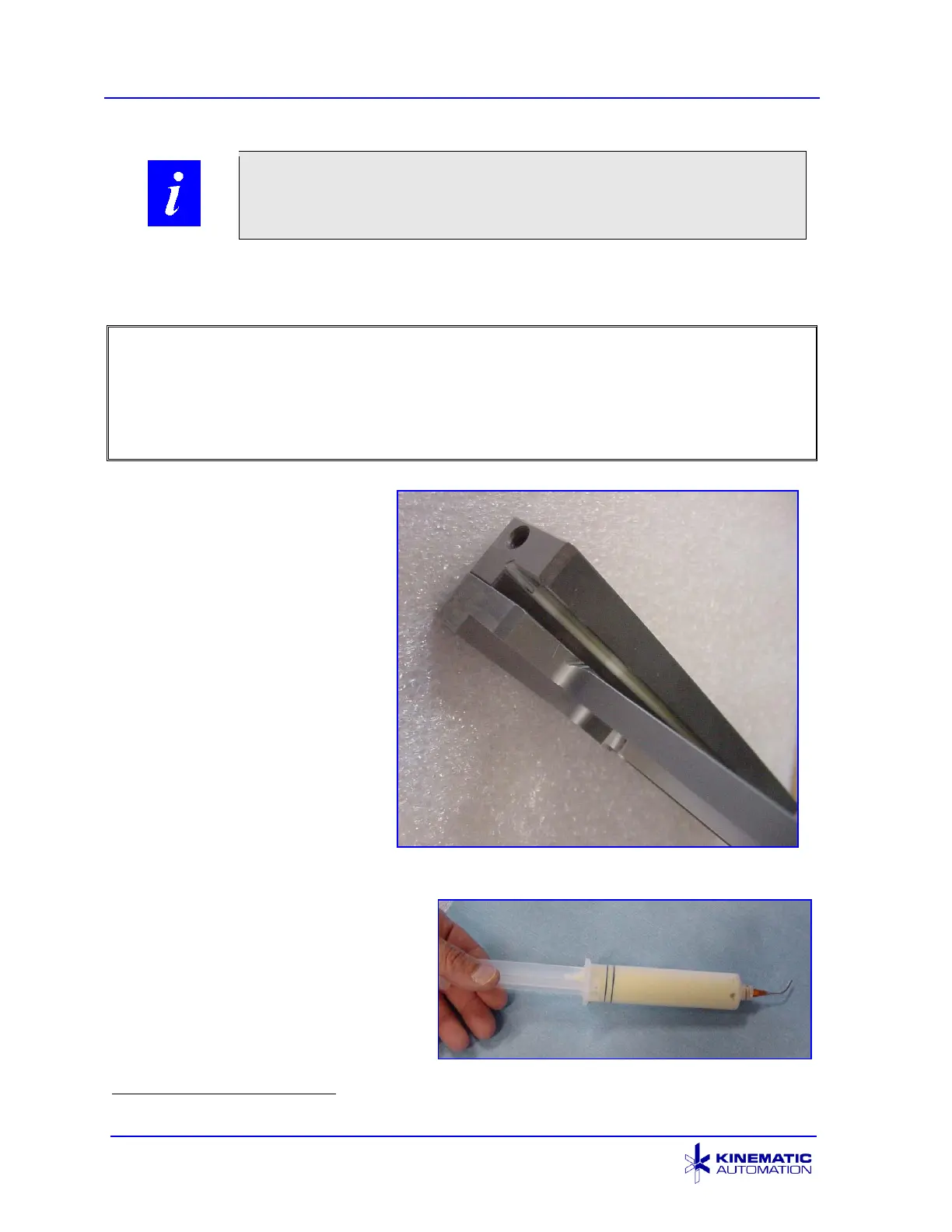

Putting grease into these grooves is

important. The following illustrations

show how a small syringe loaded

with grease is used to fill the grooves.

Grease Syringe Applicator

Loading...

Loading...