Matrix 2360 Programmable Shear User Manual - Section 7

12-092600 A 81

Add the two numbers and divide by two to get the number that should be set

in the amplifier. Set the amplifier to this number. (Refer to the third party

sensor documentation in the documentation package.) This number may be

adjusted either slightly higher or slightly lower depending on the

performance.

The amplifier may also be set using its built-in automatic adjustment

procedure. Refer to the third party sensor amplifier documentation for the

auto adjustment procedure.

The sensor amplifier settings optimized at the factory are recorded on the sheet

supplied with the unit.

7.15 HMI or PLC Replacement

If the PLC or HMI need

replacement, these

components will need to be

ordered through Kinematic

Automation. The software

must be loaded into these

components at the factory.

For a new Panasonic GT12 HMI unit, all dip

switches in the battery compartment should be in

the OFF position as shown above. No battery is

required for the HMI. The power is supplied by

the system and the battery is not required to

backup any system settings.

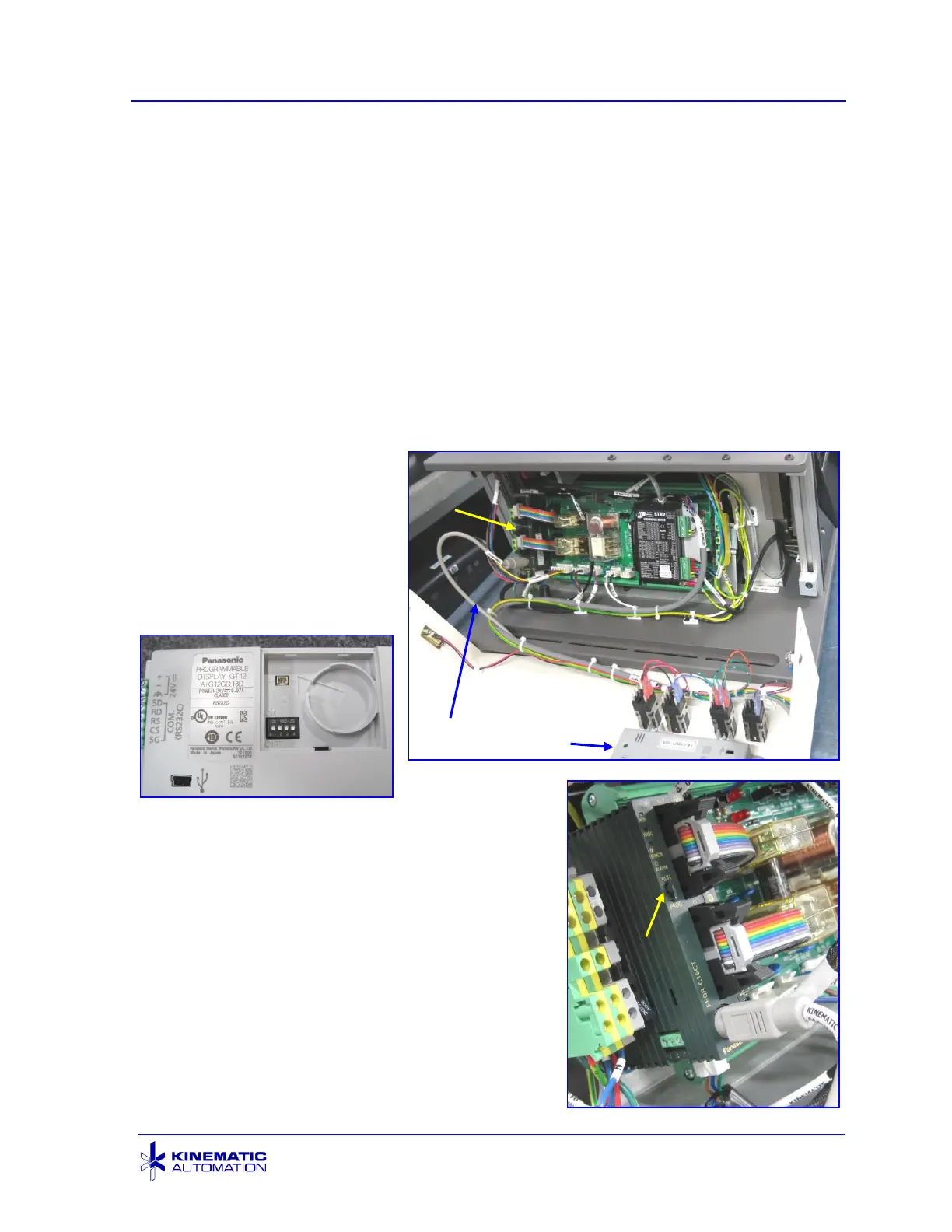

When replacing the PLC, make sure that the

RUN/PROG switch is set to the RUN position as

shown here.

Loading...

Loading...