Matrix 2360 Programmable Shear User Manual - Section 6

12-092600 A 39

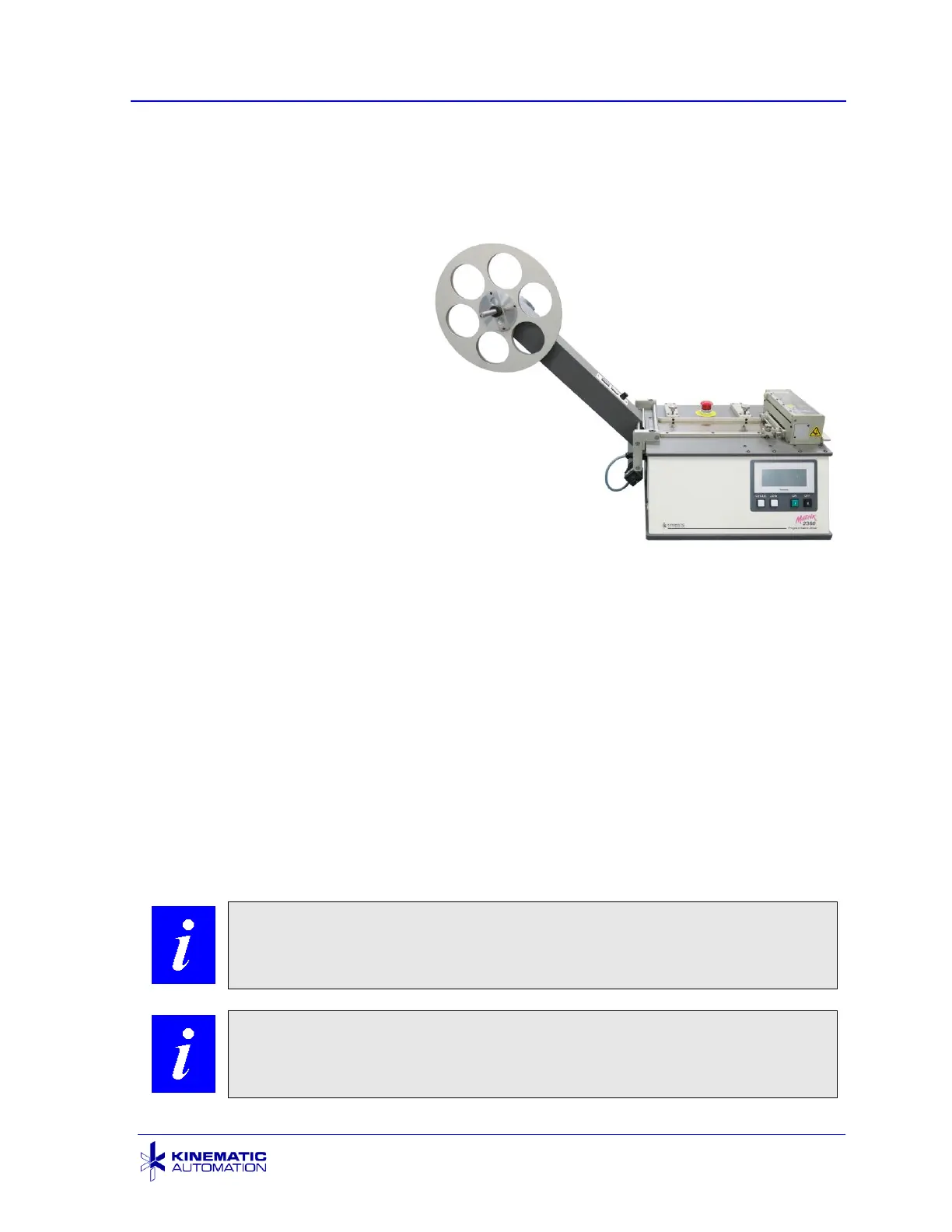

6.2 Optional Automatic Roll Feed

The Matrix™ 2360

Programmable Shear may be

equipped with an automatic roll

feed module. This allows

product material to come from a

roll. The roll feed module has

its own control panel with

POWER ON and

FORWARD/REVERSE buttons.

A free-loop sensor detects the

feed loop when there is enough

material fed, and stops the feed

motor.

When using this option, relocate

the equipment if necessary to

allow the web loop to hang

freely.

When the sensor is not blocked, meaning material should be fed again, the motor

activates to release more material, and then stops as the sensor is again blocked by

product from the roll.

The nominal material core is 7.62 cm (3”) in diameter. An oversize core is not

recommended. Use caution if mounting an oversize core to ensure that the oversize

core is centered on the spindle. There is no adapter. In some cases, an oversize

roll might ‘freewheel’, unwinding too much material.

The loop sensor can be adjusted for distance, time, on/off delay, and angle to

material. These adjustments offer optimum loop detection for varying materials.

Loading...

Loading...