Matrix 2360 Programmable Shear User Manual - Section 5

12-092600 A 33

Then press CYCLE pushbutton below the touch screen to cut 10 more sample

strips. Measure the length of these strips using calipers. Calculate and record the

average measured strip length rounded up to the nearest thousandth. (If variations

in strip length is seen, return to the instructions in

Section 5.4.2.)

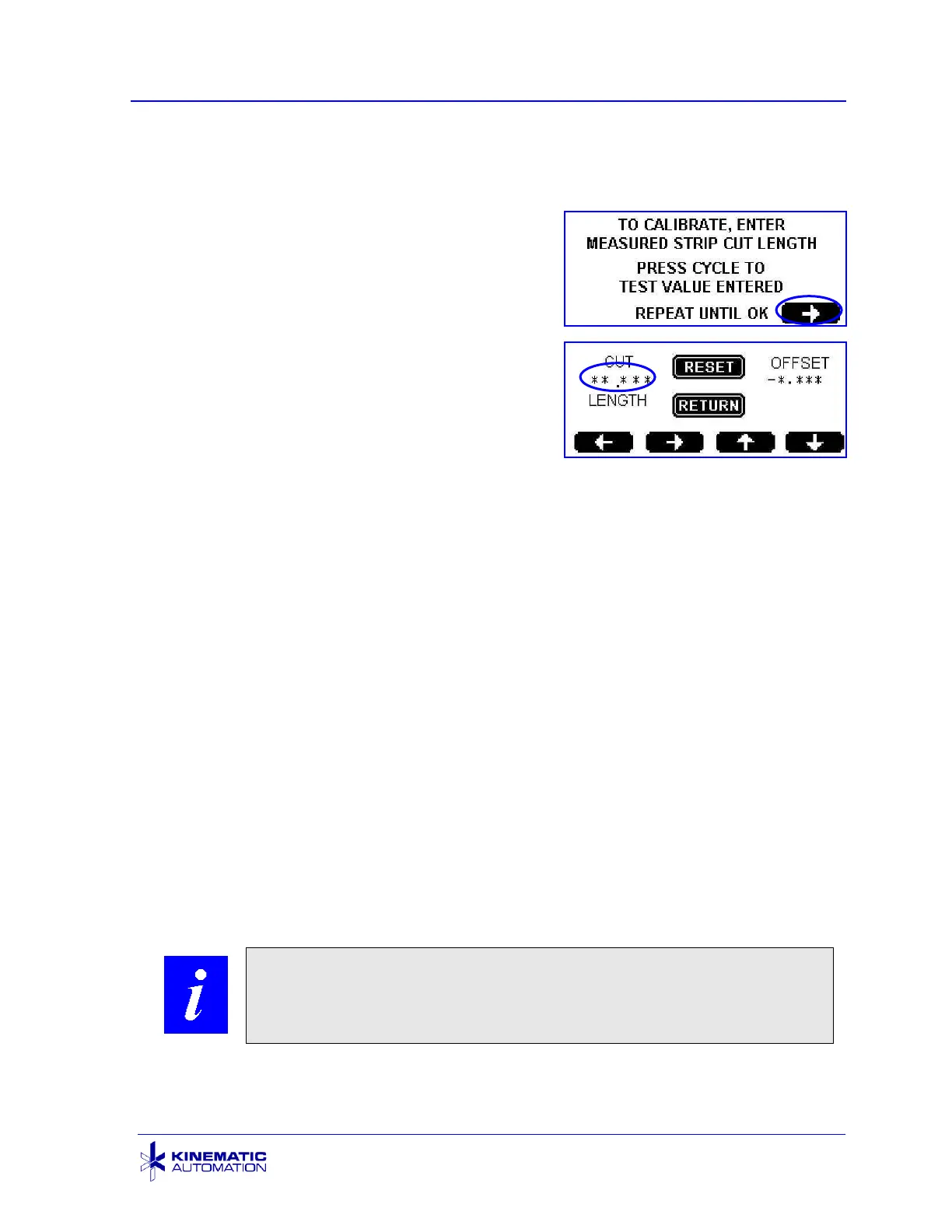

From the main screen, press the OPTIONS

button. Then press the OFFSET ADJUST button

on the Options screen.

The next screen is an instruction screen. Press

the arrow button to continue.

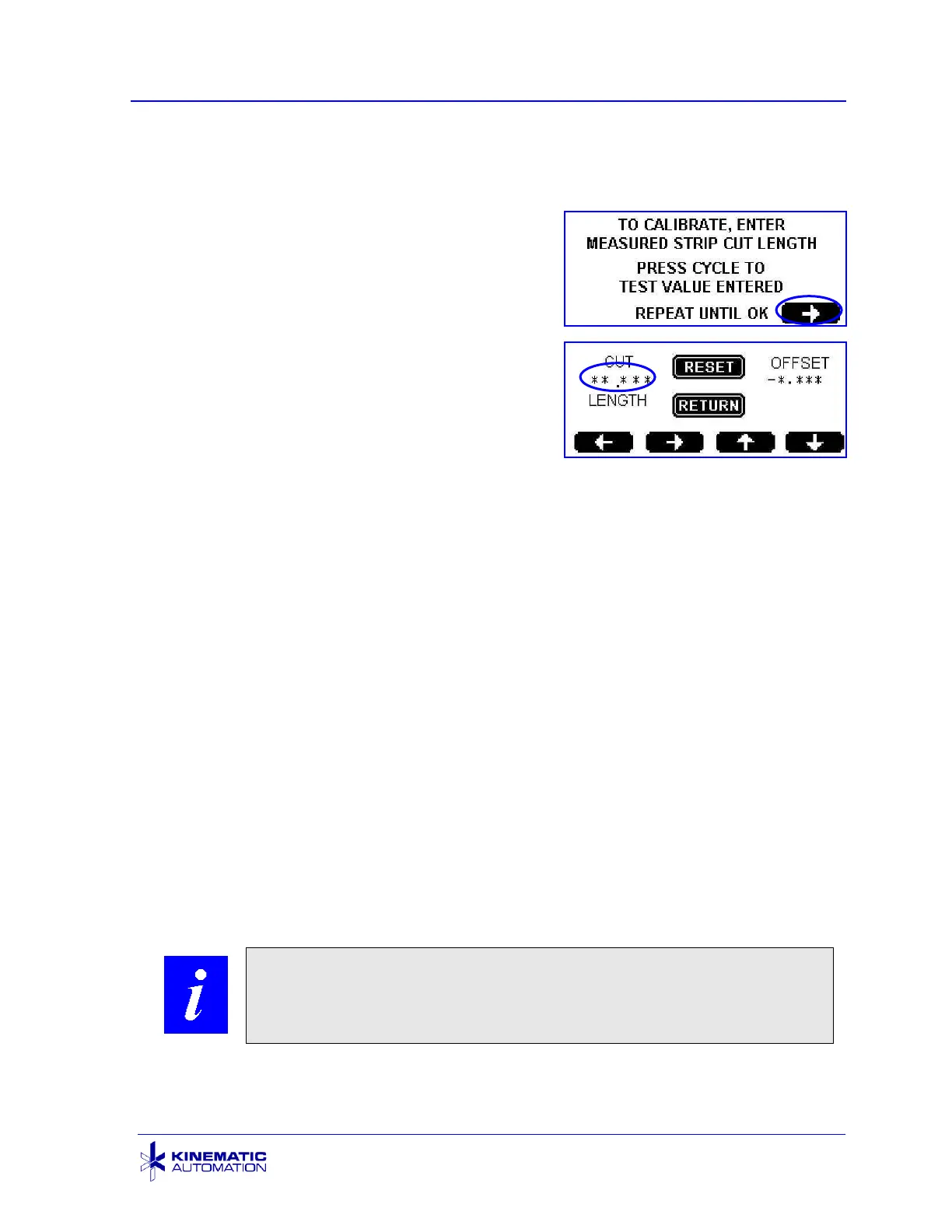

On the OFFSET ADJUST screen, touch the

screen on the cut length field. Enter the average

measured strip length that was recorded above.

Use the up and down arrows to enter numbers and the left and right arrows to select

digits. Press RETURN once to save the value.

The OFFSET field will display the deviation value (the difference between the

desired strip length and the measured strip length). If the measured length is larger

than the desired length, the OFFSET will be a negative number and future strips will

be slightly smaller. If your measured length is smaller than the desired length, the

OFFSET will be a positive number.

While still in the OFFSET ADJUST screen, press the CYCLE pushbutton below the

touch screen to cut more strips. Measure them and compare the measurement to

the desired strip length. If the new measurement is still outside of your company’s

tolerance range, enter the new average measured value on the screen, cut more

strips and re-measure. (If variations in strip length is seen, return to the instructions

in Section 5.4.2.) Continue this process until the cut strips are within tolerance.

When the desired strip length has been reached, press the RETURN button to return

to the MAIN SCREEN.

The RESET button will return the OFFSET to zero. A warning screen will display

before the value is reset. (See the warning screen in section 5.3.7.3.)

Loading...

Loading...