FINAL DRIVE REASSEMBLY

7F - 20

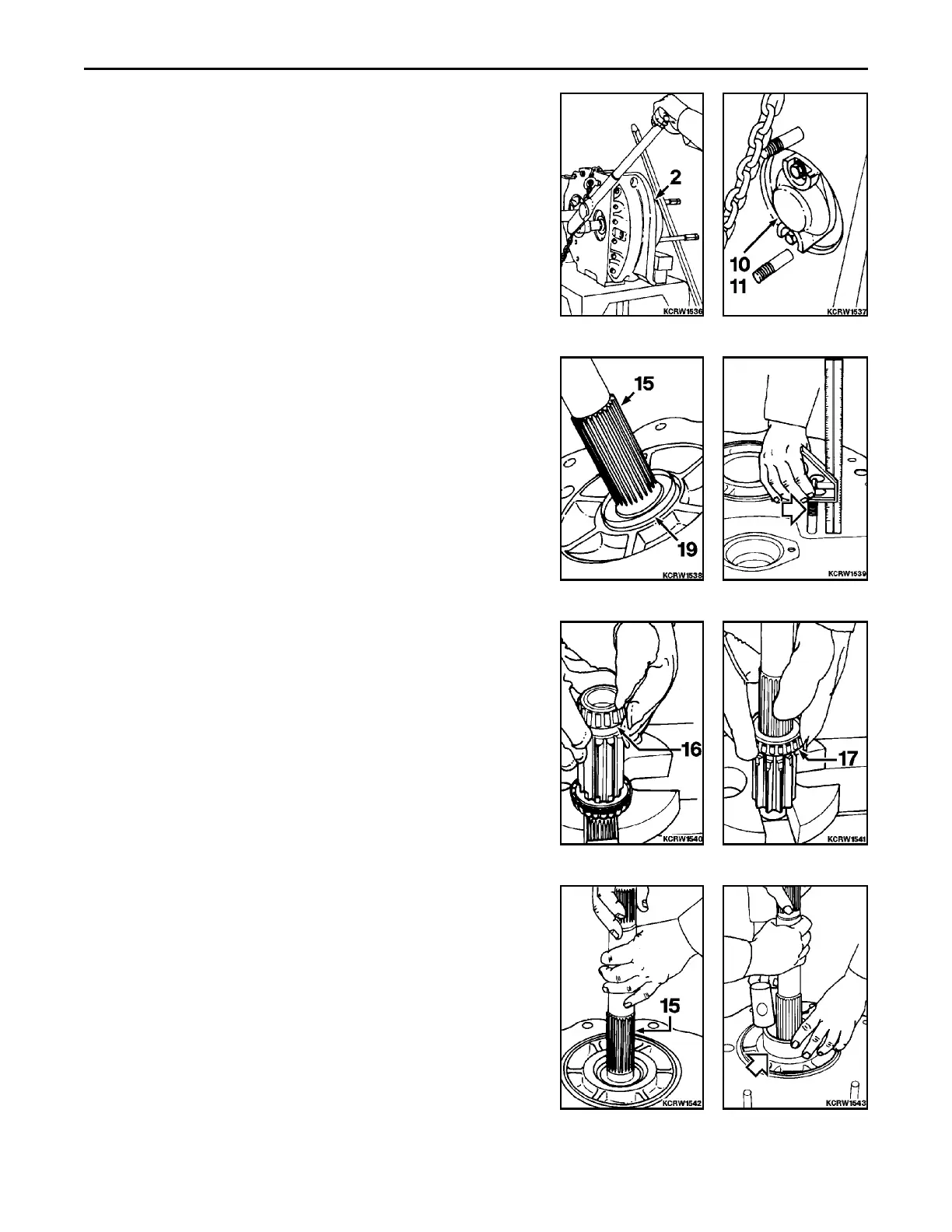

22. D32E-1 or D38E-1: Assemble two ¾NF bolts in opposite holes

of sprocket carrier shaft (2). Position pry bar to prevent shaft

rotation. Torque sprocket carrier shaft retainer bolt to 305 NCm

(225 lbf ft).

D32P-1 or D38P-1: Assemble two ¾NC bolts in opposite holes

of sprocket carrier shaft (2). Position pry bar to prevent shaft

rotation. Torque sprocket carrier shaft retainer bolt to 305 NCm

(225 lbf ft).

Now remove longer bolt and two carrier washers. Install bolt (9)

and torque to 475 NCm (350 lbf ft).

24. Assemble carrier shaft cover (11) and gasket (10). Secure with

hardware. Torque bolts to 60 NCm (45 lbf ft) ±10%.

25. Carefully work shaft oil seal (19) (spring garter facing out) down

pinion shaft (15), being careful not to cut sealing lip surface.

Using a suitable driver, press pinion shaft seal edge flush with

shoulder.

D39E-1 OR D39P-1

REMARK

Callouts from exploded view correspond with callouts in following

steps.

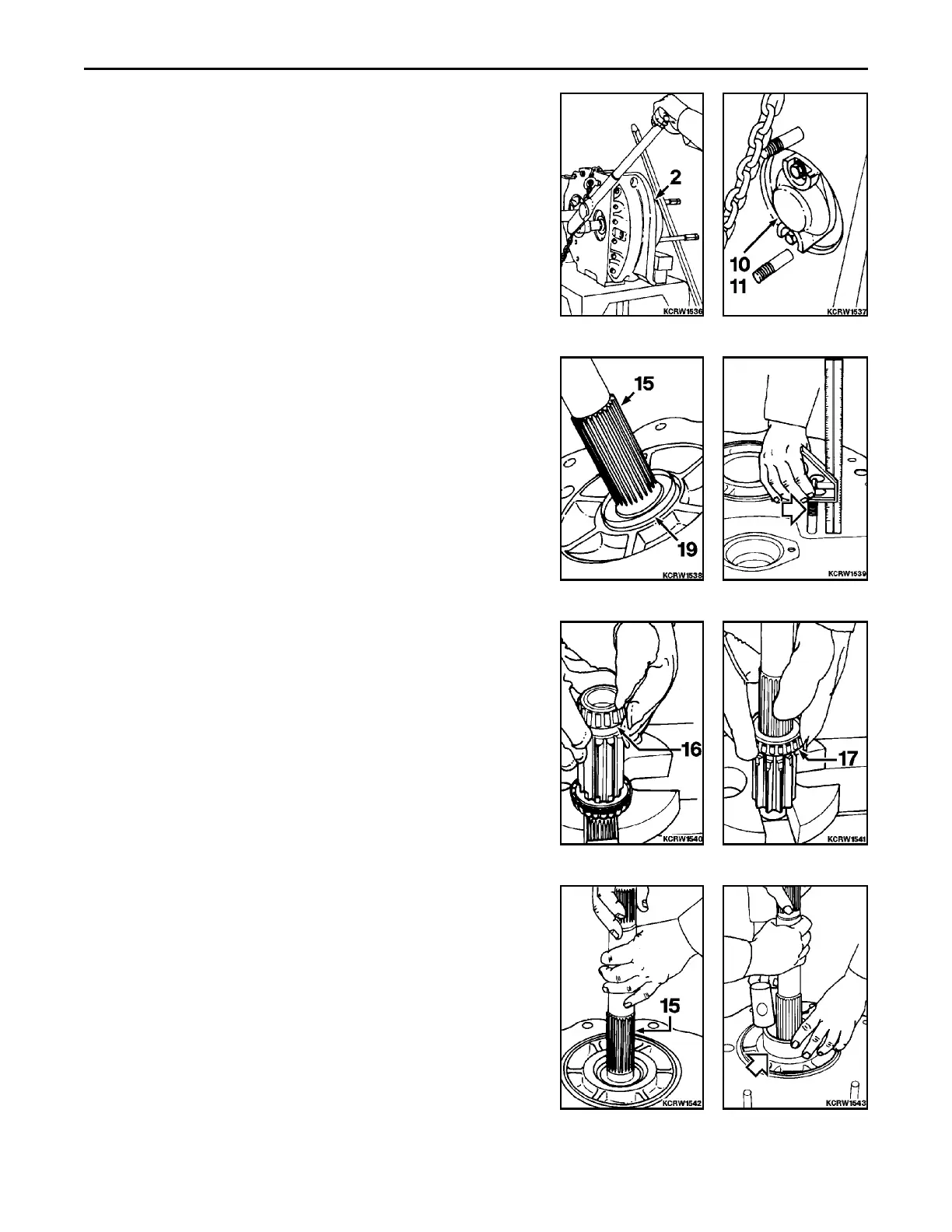

1. Block final drive housing in a horizontal position with rear main

frame mating face up. Check height of two mounting studs for

65 mm (2.56 in) dimension. If necessary to install new studs,

apply Loctite #568 or Plastic Gasket before installing. If neces-

sary, assemble pinion shaft outer bearing cup (16) to housing.

Using a driver, tap to seat in housing.

2. Heat pinion shaft outer bearing (16) to 135EC (275EF) for 45

minutes and assemble to shaft. Tap to seat against shoulder of

shaft.

3. Invert shaft. Heat pinion shaft inner bearing (17) to 135EC

(275EF) for 45 minutes and assemble to shaft. Tap to seat

against shoulder of shaft.

4. Prelube pinion shaft bearings and set shaft (15) into outer

bearing cone.

5. Using driver, install inner bearing cup, while rotating shaft, until

a slight resistance to rotation is felt.

Loading...

Loading...