RIPPER CYLINDERS

10C - 13

RIPPER CYLINDER REMOVAL

1. Retainer Ring 15. Lock Nut

2. Cylinder Gland 16. Rod Bushing

3. Rod Wiper

q

4. Rod Seal

q

5. Buffer Ring

q

6. O-Ring

q

7. Back Up Ring

q

8. O-Ring

q

9. Wear Ring

q

10. Seal Ring

q

11. O-Ring

q

12. Wear Ring

q

13. O-Ring

q

14. Cylinder Piston

17. Cylinder Rod

18. Barrel Bushing

19. Cylinder Barrel

q

- Part of Cylinder Seal Kit

SPECIFICATIONS

Bore and Stroke ........................................................... 76.2x172.72 mm (3x6.8 in)

Weights ............................................................................31 kg (69 lbs)

Torques - Piston Lock Nut ............................................ 610 to 678 NCm (450 to 500 lbf ft)

Seal Test Pressure .............................................................. 2750 kPa (400 psi)

Rod End Travel .............................................. Not to Exceed 1 mm (0.039 in) Per Minute

REMOVAL

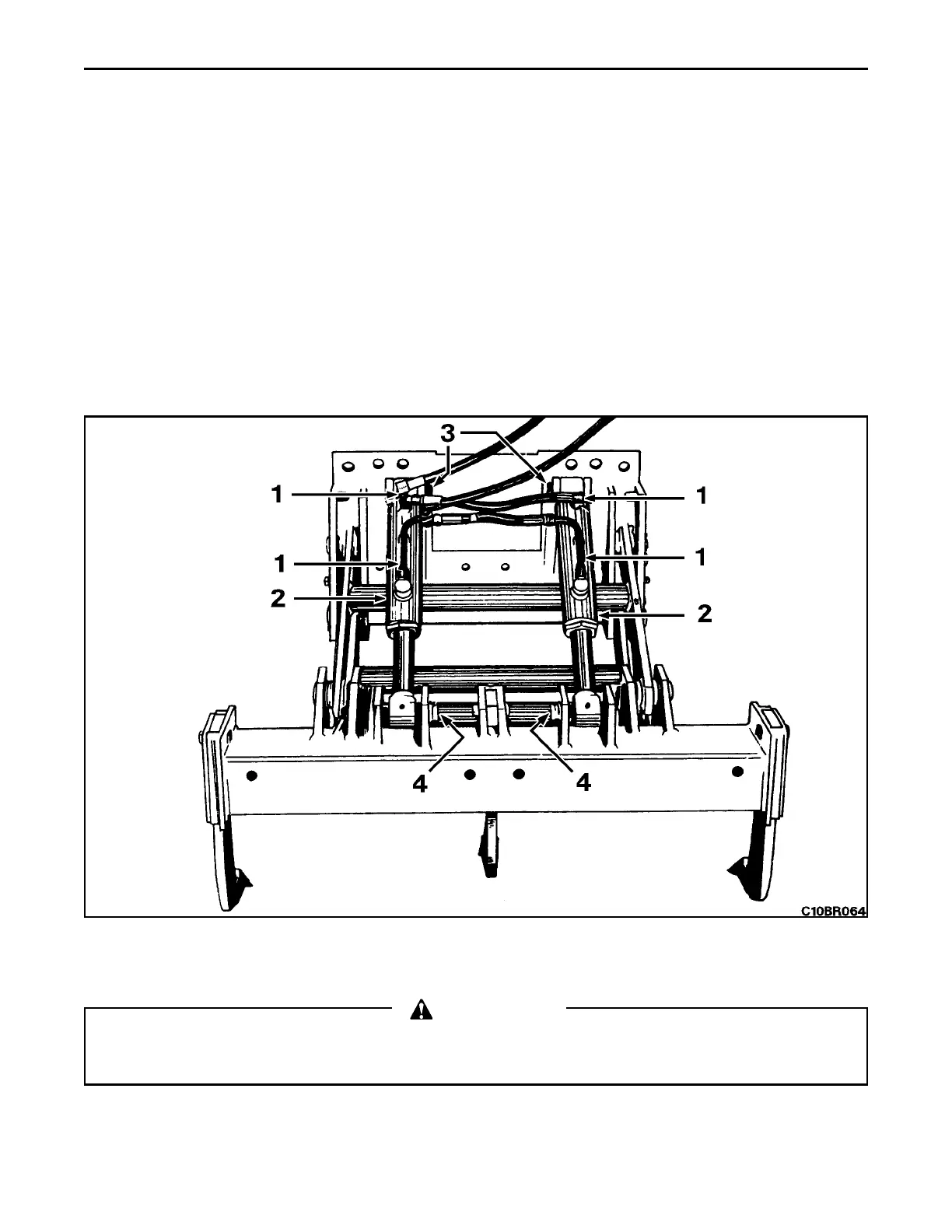

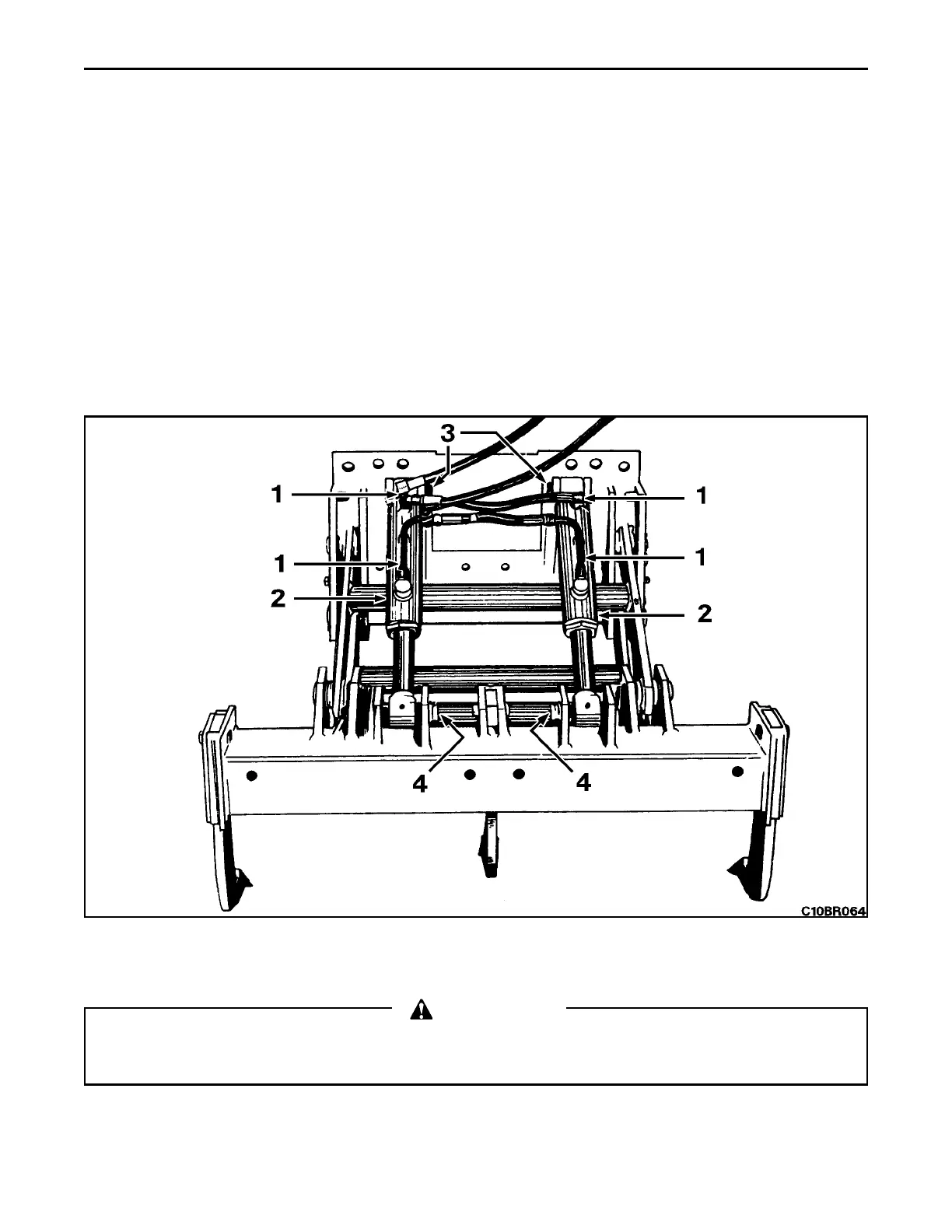

1. Ripper Cylinder Hoses 3. Front Mounting Pin

2. Ripper Cylinder 4. Rear Mounting Pin

WARNING

Park machine on level ground, and stop engine, lower the blade and all attachments to the ground, lock

the transmission shift lever in neutral, apply the brake pedal lock, and turn off electrical system master

switch.

1. Operate equipment control lever to relieve any pressure in system. Disconnect and cap hoses (1) at cylinder (2).

Drain into a suitable container. Attach hoist and sling to cylinder. Remove front (3) and rear (4) mounting pins from

cylinder and remove.

Loading...

Loading...