UNDERCARRIAGE METAL TYPE FACE SEALS

14 - 54

SEAL INSTALLATION

REMARK

Cleanliness is critical when handling seals. Never handle seal with greasy,

oily or dirty hands. Do not drop, bump or roughly handle seals.

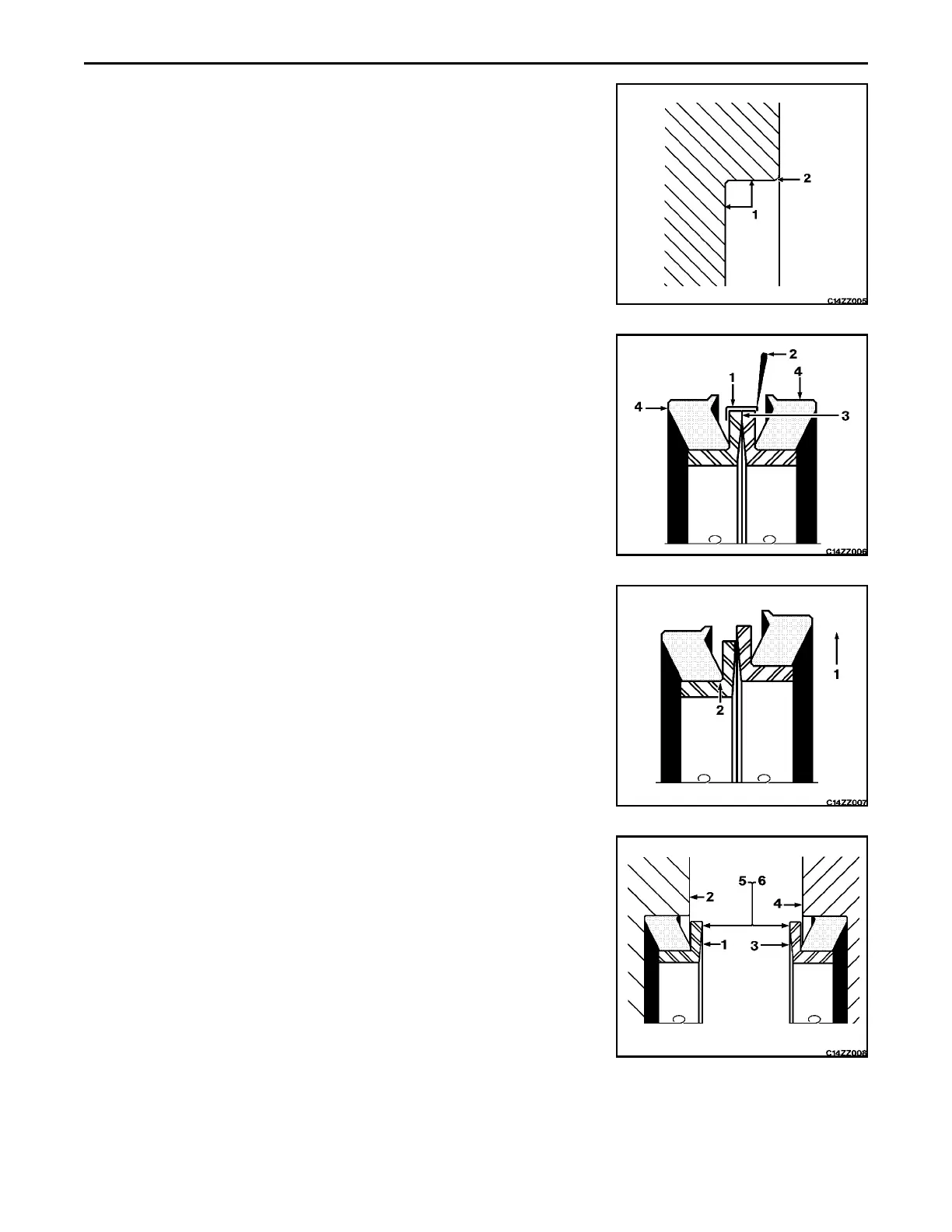

1. Remove any corrosion or hardened material that may exist on surface

(1) that contact rubber rings. Use a non petroleum base solvent and wipe

dry with a lint free wrapper. Make sure outer edge (2) is free of burrs.

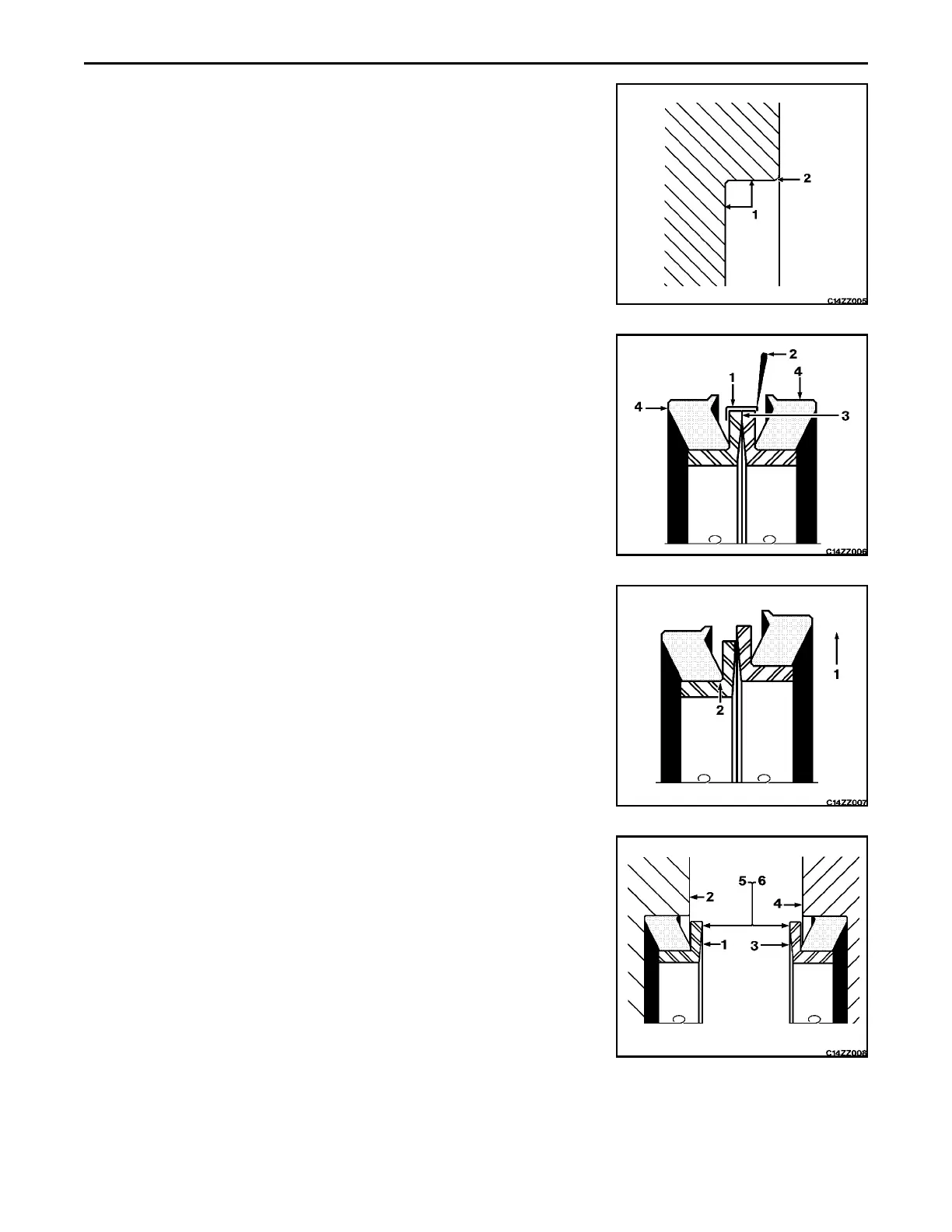

2. Break plastic protector band (1) if applicable, by inserting a sharp tool (2)

at edge of band. Be careful not to scratch or damage seal faces (3). Do

not cut or damage rubber rings (4).

3. Carefully remove plastic band and gently "slide" (1) two seal halves

apart. Metal ring faces must not be damaged or contaminated. Check to

be sure rubber rings are flush (2) against inside shoulder of metal ring.

4. Install one seal half (1) into receptacle (2) so protruding lip just contacts

seal bore. Press with both clean hands (180E apart) against metal ring

until rubber ring is evenly seated against bore shoulder. Make sure seal

is not cocked in bore. Repeat procedure for other seal half (3) and

receptacle (4). Wipe both metal ring sealing faces clean (5) with a lint

free wiper. Apply a light coat (6), just enough to wet faces, of clean

lubricant to seal faces of metal rings.

Loading...

Loading...