REASSEMBLY FINAL DRIVE

7F - 17

D32E-1, D32P-1, D38E-1 OR D38P-1

REMARK

Callouts from exploded view correspond with callouts in following

steps

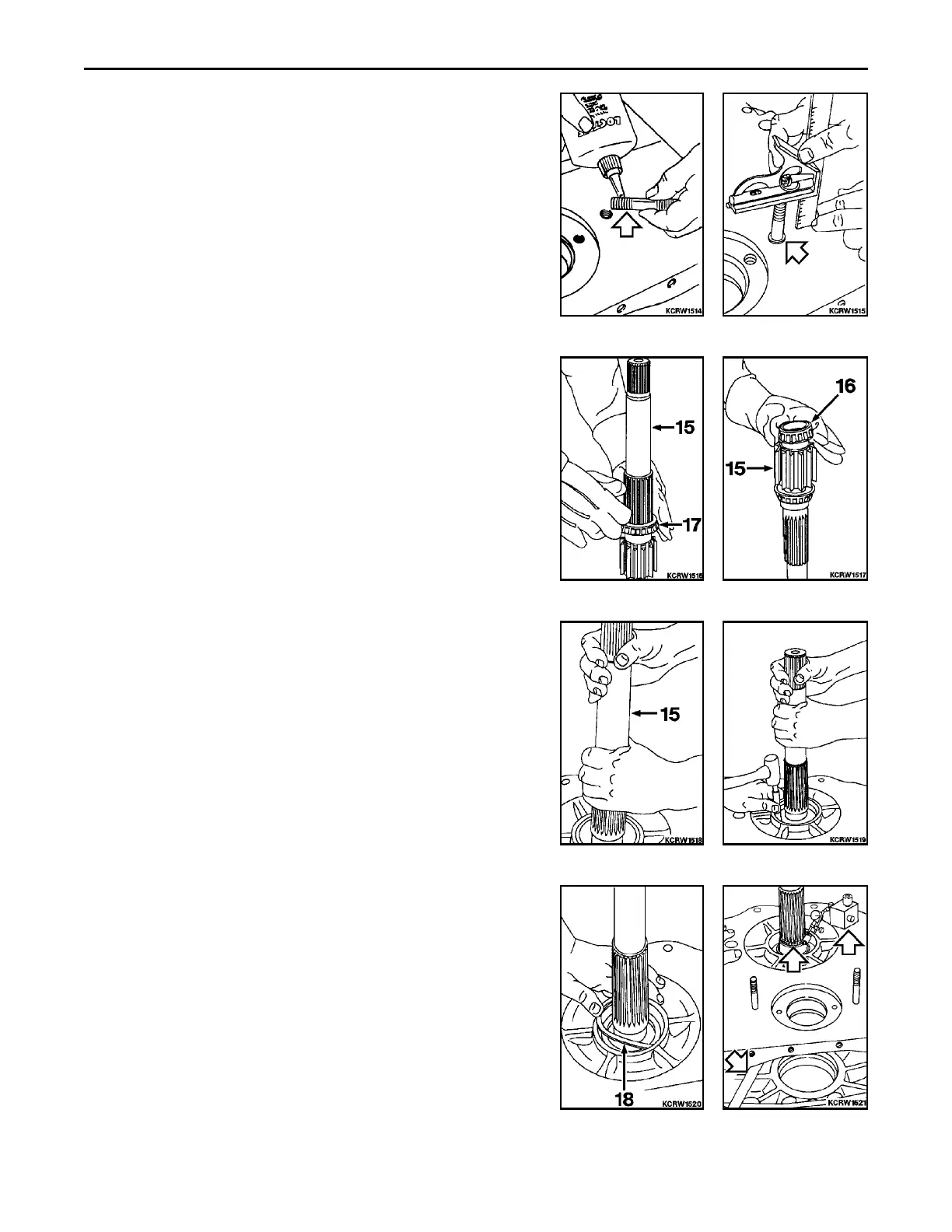

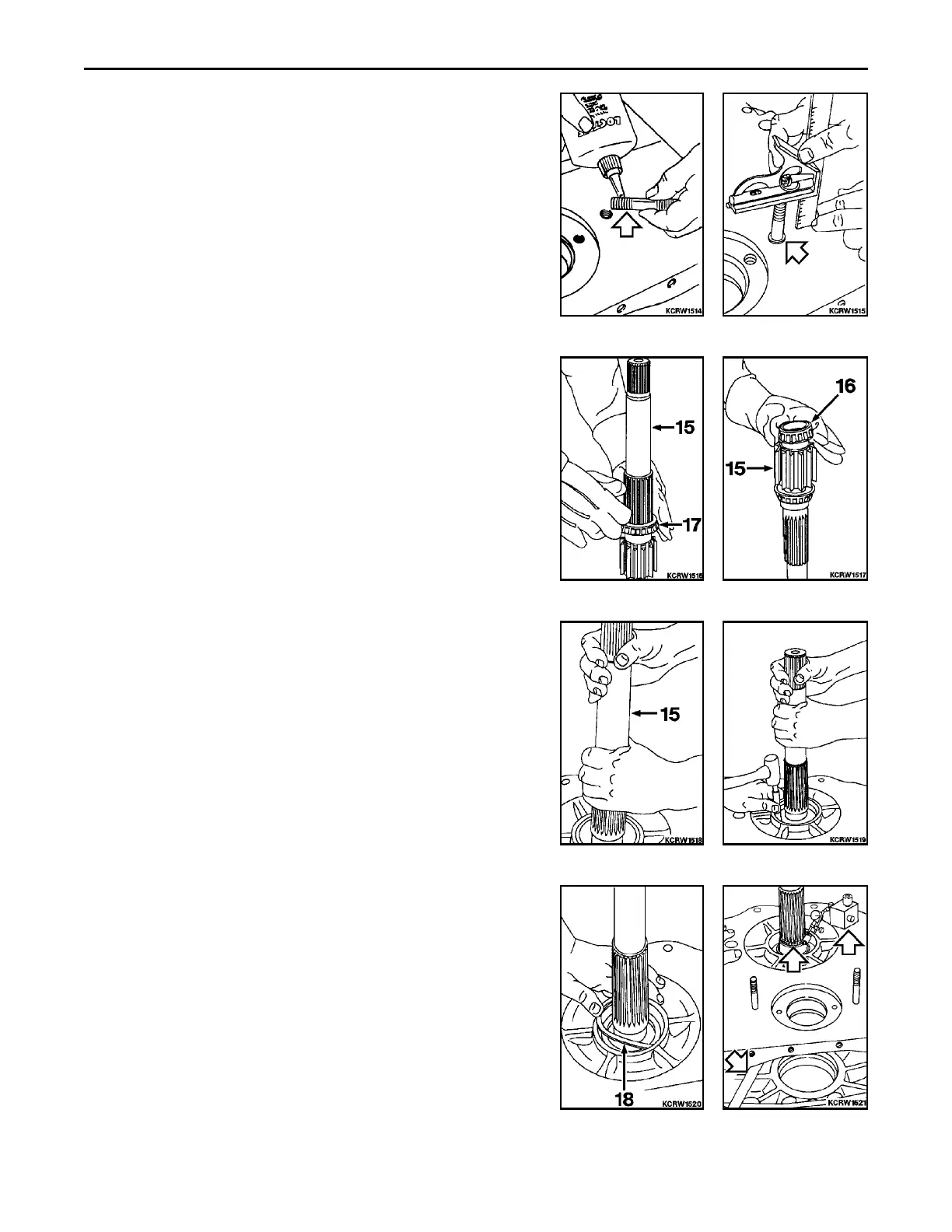

1. Block final drive housing in a horizontal position with rear main

frame mating face up. Check height of two mounting studs for

65 mm (2.56 in) dimension. If necessary to install new studs,

use Loctite #568 or Plastic Gasket.

2. Assemble studs to housing and set to 65 mm (2.56 in) dimen-

sion. If necessary, assemble drive pinion outer bearing cup (16)

into housing. Using a driver, tap to seat in housing.

3. Heat drive pinion inner bearing (17) to 135EC (275EF) for 45

minutes and assemble to shaft (15). Tap to seat against

shoulder of shaft.

4. Heat drive pinion outer bearing (16) to 135EC (275EF) for 45

minutes and assemble to shaft (15). Tap to seat against

shoulder of shaft.

5. Prelube drive pinion bearings and set shaft (15) into outer

bearing cone.

6. Using driver, install inner bearing cup until a slight resistance to

rotation is felt.

7. Attempt to insert 2.769 mm (0.109 in) retaining ring (18). If

possible to insert ring, bump cup back against ring with slide

hammer. If shaft rotates freely assembly is complete.

8. Position indicator against hose clamp assembled to shaft. Set to

zero. Insert pry bar between housing and shaft. Pry shaft

upward from within housing to determine end play. Observe and

record reading. Repeat two or three times and average read-

ings. Required end play is 0 to 0.229 mm (0 to 0.009 in). If end

play should exceed 0.229 mm (0.009 in) with 2.769 mm (0.109

in) retaining ring, install 2.972 mm (0.117 in) ring and bump cup

back against ring. If 2.769 mm (0.109 in) retaining ring will not

fit, or shaft will not rotate freely, install 2.565 mm (0.101 in)

retaining ring and bump cup back against retaining ring.

Loading...

Loading...