2G6

2-1-15

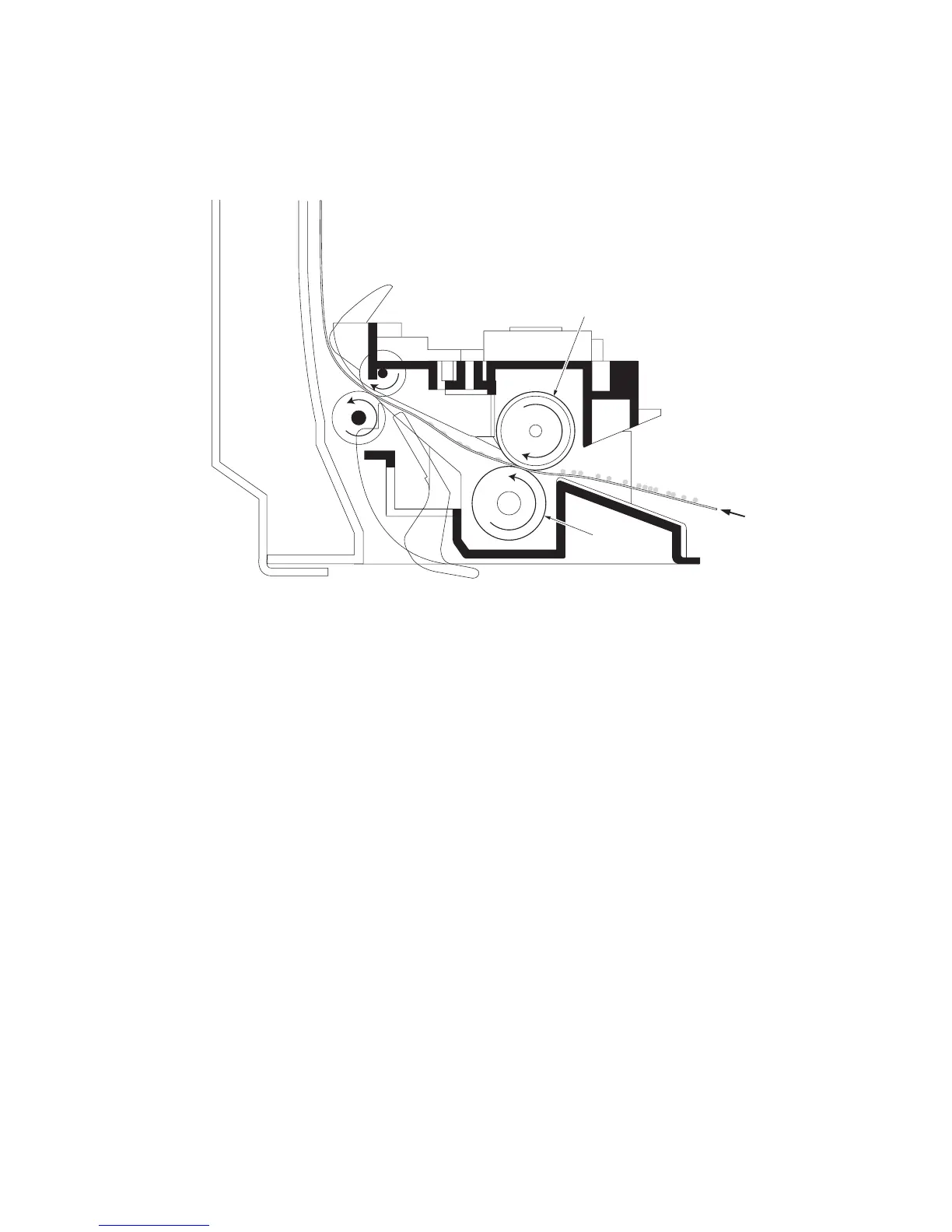

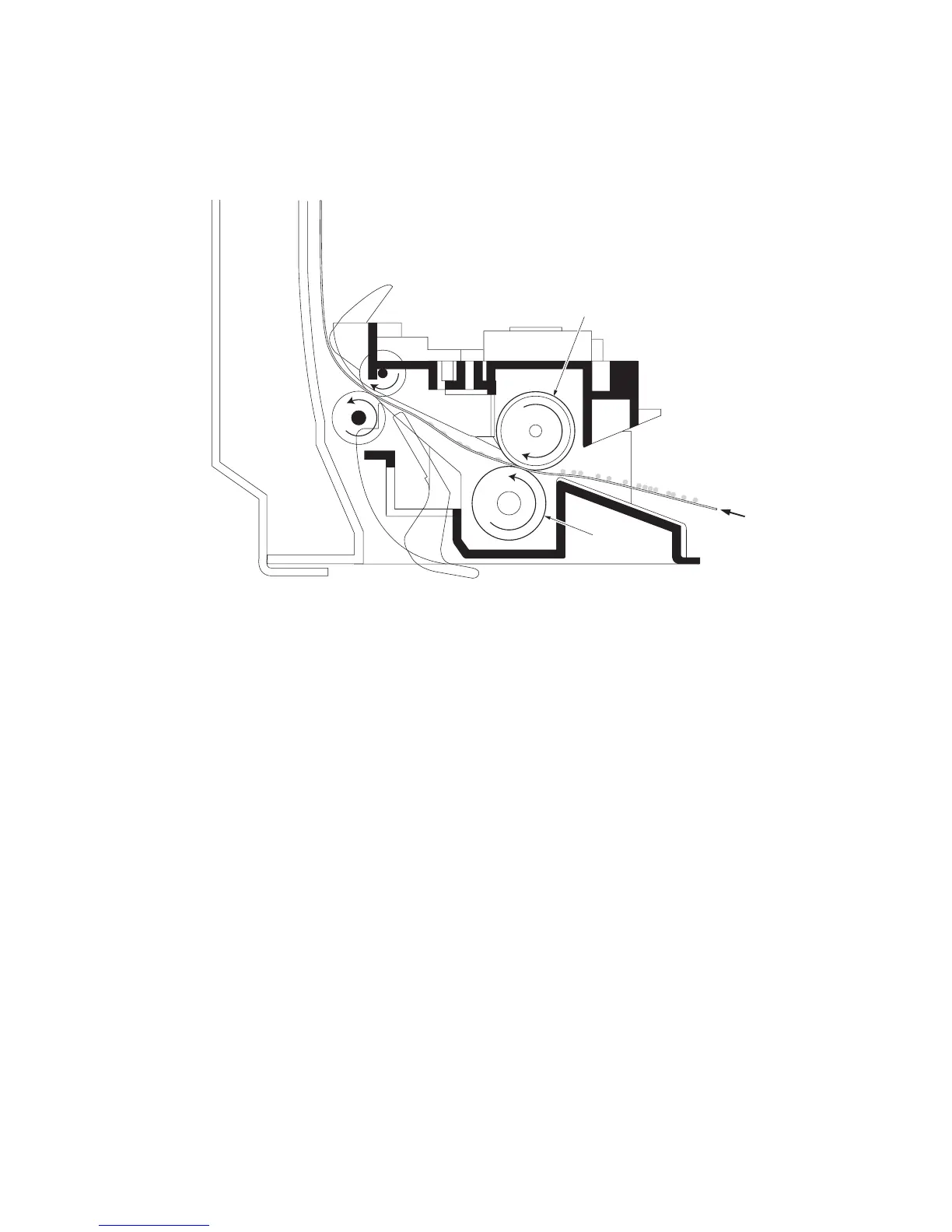

(6) Fusing

The toner on the paper is molten and pressed into the paper as it passes between the heat roller (A) and the press roller

(B) in the fuser unit.

Figure 2-1-15 Fusing

The heat roller has a halogen lamp inside which continuously turns on and off by the thermistor to maintain the constant

temperature onto the heat roller surface.

The heat roller is resin coated by florin to prevent toner from accumulating on the roller after a long run. Care must be

taken while handling the heat roller not to scratch the roller surface as doing so may result in print problems.

The heat roller has four claws which are continuously in contact with its surface. These claws prevent the paper on

which toner has been fused from being wound around the heat roller causing paper jam.

The pressure roller is made of the heat-resistant silicon rubber. This roller is used to strongly press the paper towards

the heat roller by means of coil springs.

The temperature of the heat roller is constantly monitored by the engine board using the thermistor and triac. Should the

temperature of the heat roller exceed the predetermined value, the thermal cutout is activated to effectively disconnect

the heater (halogen) lamp from power.

(A)

(B)

Loading...

Loading...