LNC-Lathe New T6-Series

CNC Operation

50 LNC Technology Co., Ltd.

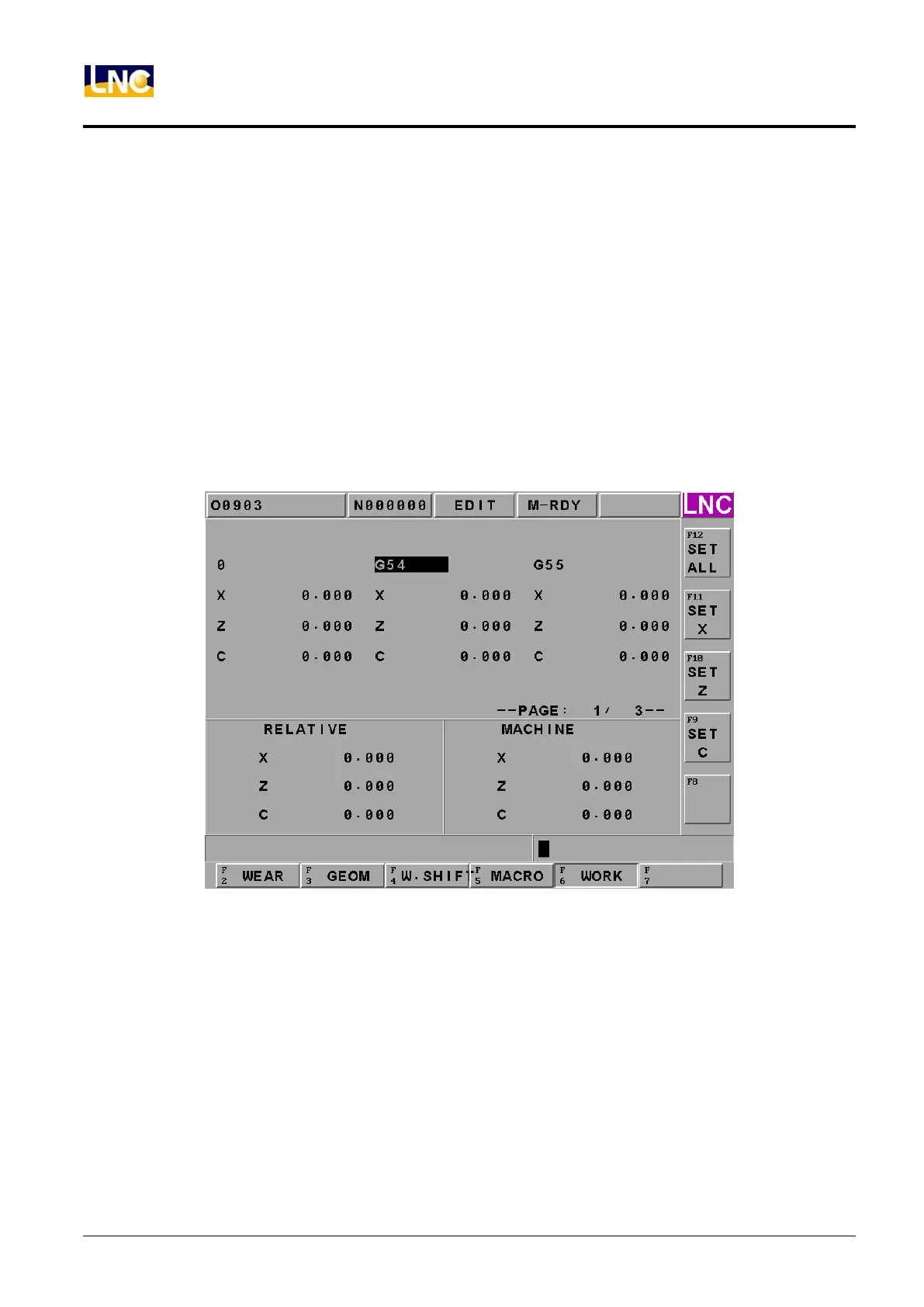

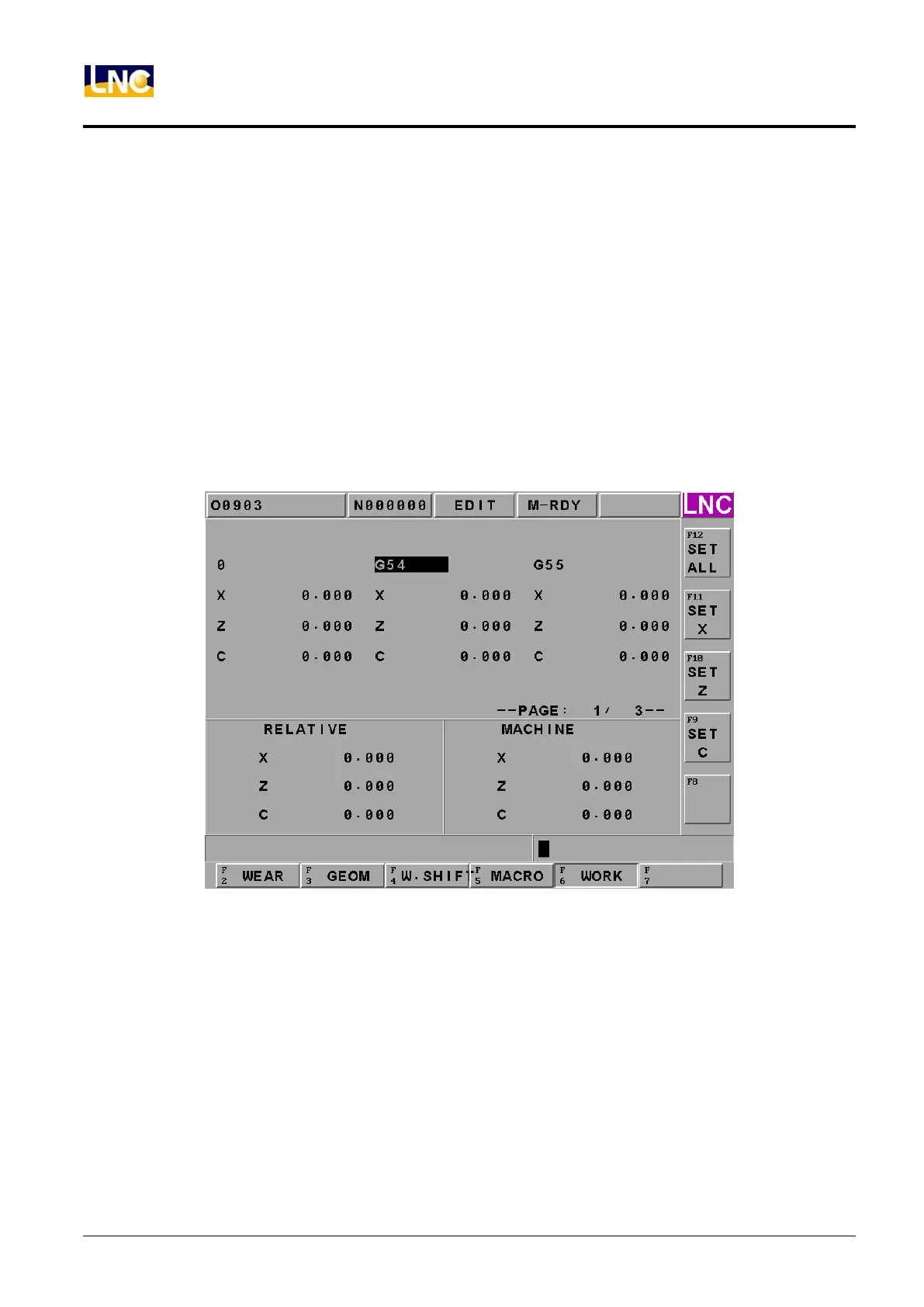

1.5.5 WORK

Pressing 【WORK】 button to enter into the working coordinate setting screen.

1. The controller provides working coordinate system for users. Users can execute the following settings such

as G0、G54、G55、G56、G57、G58、G59、G54P1~P300. Also, using <PAGE↓> and <PAGE↓> key to

switch screen.

2. Using direction keys to move cursor to the wanted change column and to key-in the setting value Xxxx

(i.e.:X100 or Z200 )in the enter rows. Then, the selected coordinate value will be updated immediately

by pressing <INPUT> key

3. Users are able to write 2 axes at the same time, such as Xxxx. Zxxx. But, remember to put decimal point in

order to prevent confusion(i.e., X100. Z200.)

Controller offers【Teach in】functions for users to input working coordinates. Go to【TEACH IN】work setting page,

use measuring instruments to touch workpiece and then press X set,Y set, Z set, C set .Controller will

automatically set each axis.

SET ALL :Set current machine’s each axis coordinate into【TEACH IN】’s working coordinates.

X SET :Set X Axis’ machine coordinates value into working coordinates which the cursor stops.

Z SET :Set Z Axis’ machine coordinates value into working coordinates which the cursor stop.

C SET :Set C Axis’ machine coordinates value into working coordinates which the cursor stop.

Loading...

Loading...