IMPULSE•G+ Mini Advanced Instruction Manual – March 2014

5-33

Tuning

These parameters help tune the motor for your application, which include Torque Compensation and

S-Curve characteristics for smoother transition during machine acceleration and deceleration. Below

are the parameters included in this section.

• D1 DC Injection

• D2 Automatic Slip Compensation

• D3 Torque Compensation

• D8 Dwell Function

• D9 S-Curve Acceleration/Deceleration

• D10 Carrier Frequency

• D11 Hunting Prevention

DC Injection

DC Injection can be used to stop a motor whose rotational direction is uncertain at start-up.

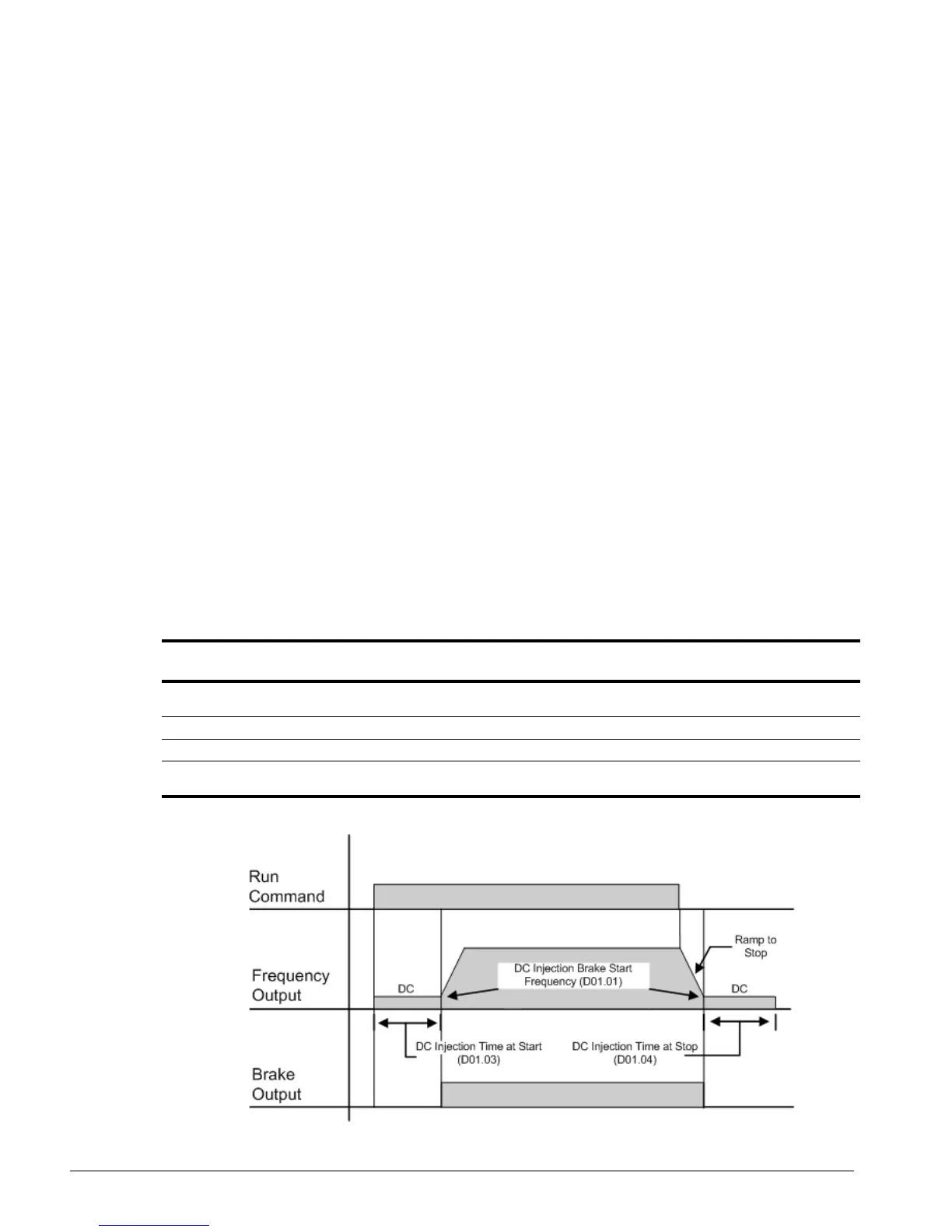

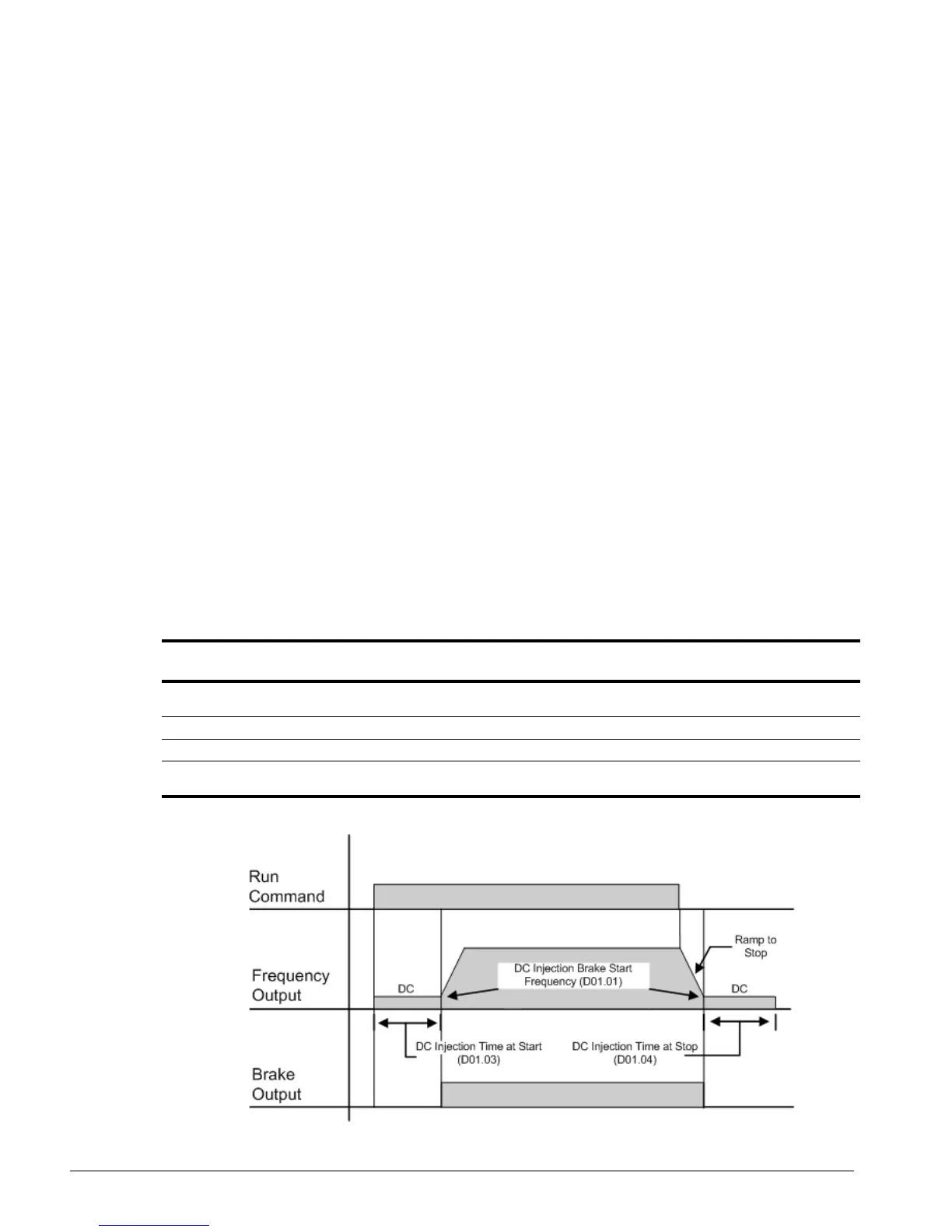

With Decel to Stop enabled (B03.03 = 00), upon removal of the run command the IMPULSE•G+

Mini drive controls motor deceleration according to the Decel Time setting, until output frequency

reaches the DC Injection Braking Start Frequency (D01.01 setting). Then the drive output is turned

off and DC injection current is applied to the motor. The effective DC injection time and current

should be set to provide adequate stopping without excessive motor heating. The DC injection

voltage is determined by the DC injection braking current and motor impedance.

Figure 5-20: DC Braking Sequence

Parameter

Code Name Function Range Initial Value

Access

Level

D01.01 DC Injection Start Frequency DC Injection braking

frequency start.

0.0–10.0 Hz 0.5 Basic/Adv

D01.02 DC Injection Current % of Inverter rated current. 0–75% 50 Basic/Adv

D01.03 DC Injection Time @ Start DC Injection braking time. 0.00–10.00 sec 0.00 Basic/Adv

D01.04 DC Injection Time @ Stop DC Injection braking time at

stop.

0.00–10.00 sec 0.05 Basic/Adv

Loading...

Loading...