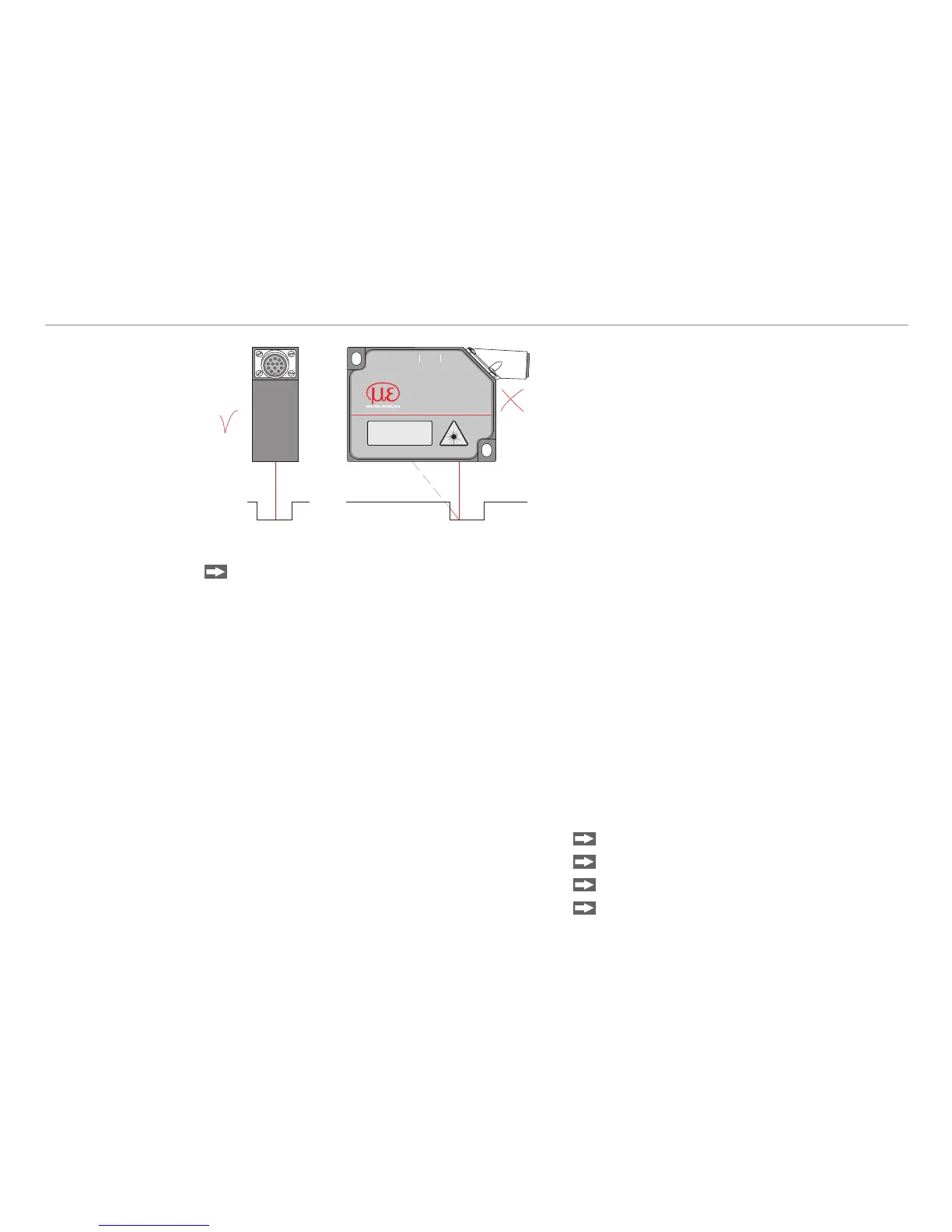

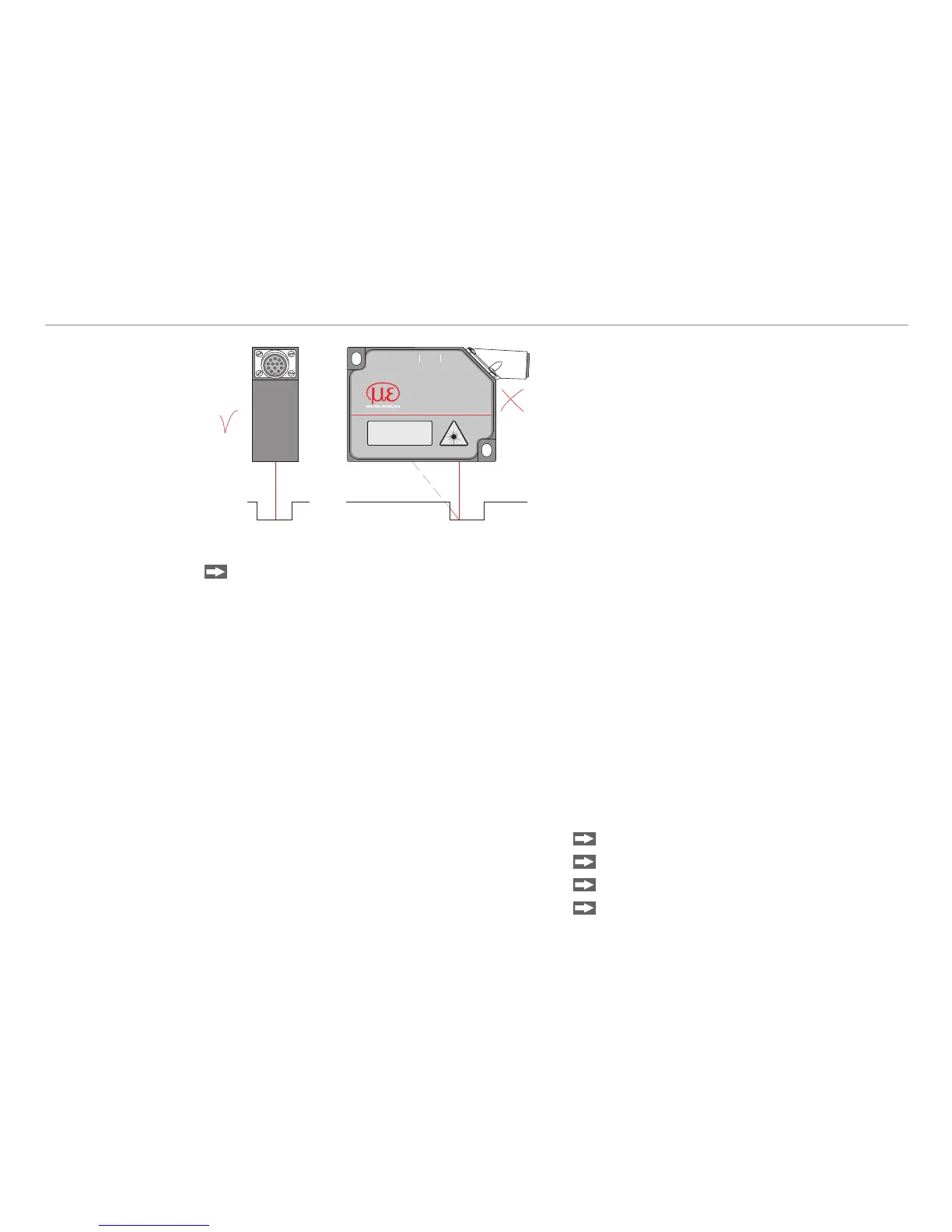

In case of bore holes, blind holes, and edges in

the surface of moving targets the sensor must

be arranged in such a way that the edges do not

obscure the laser spot (Fig. 24).

Sensor arrangement for holes and ridgesFig. 24:

Cleaning the Protective Glasses9.4

Clean the protective glass with high-percentage alcohol (propanol or optics cleaner) and a lint-free lens

cleaning paper or an optics cleaning cloth (from the optics or photo shop).

The surface is damaged if a dry cloth is used for cleaning.

Default Setting10.

Data protocol ILD1402 -

Current output with error value (3.75 mA) -

Measuring rate : 1.5 kHz -

Interface: 115.2 kBaud, binary format (no ASCII) -

Moving average avg =1 (no averaging) -

Teach value 1: 0.0 -

Teach value 2: 16368.0 -

External input for scaling -

Continuous measurement output -

Output time: 500 ms, -

Key lock after 5 min power on -

Settings saved into FLASH -

Measuring range: -

100 % FSO: I = 20 mA , digital 16207

0 % FSO: I = 4 mA, digital 161

Maximum output (101 % FSO): -

20.16 mA / digital 16367

Minimum output (-1 % FSO): -

3.84 mA / digital 0

Set sensor on default settings:

Switch off the senors power supply.

Keep the key “Select“ pressed.

Switch on the sensors power supply.

Wait about 5 sec.

Loading...

Loading...