14. Maintenance

MiR600 User Guide (en) 08/2021 - v.1.0 ©Copyright 2021: Mobile Industrial Robots A/S. 211

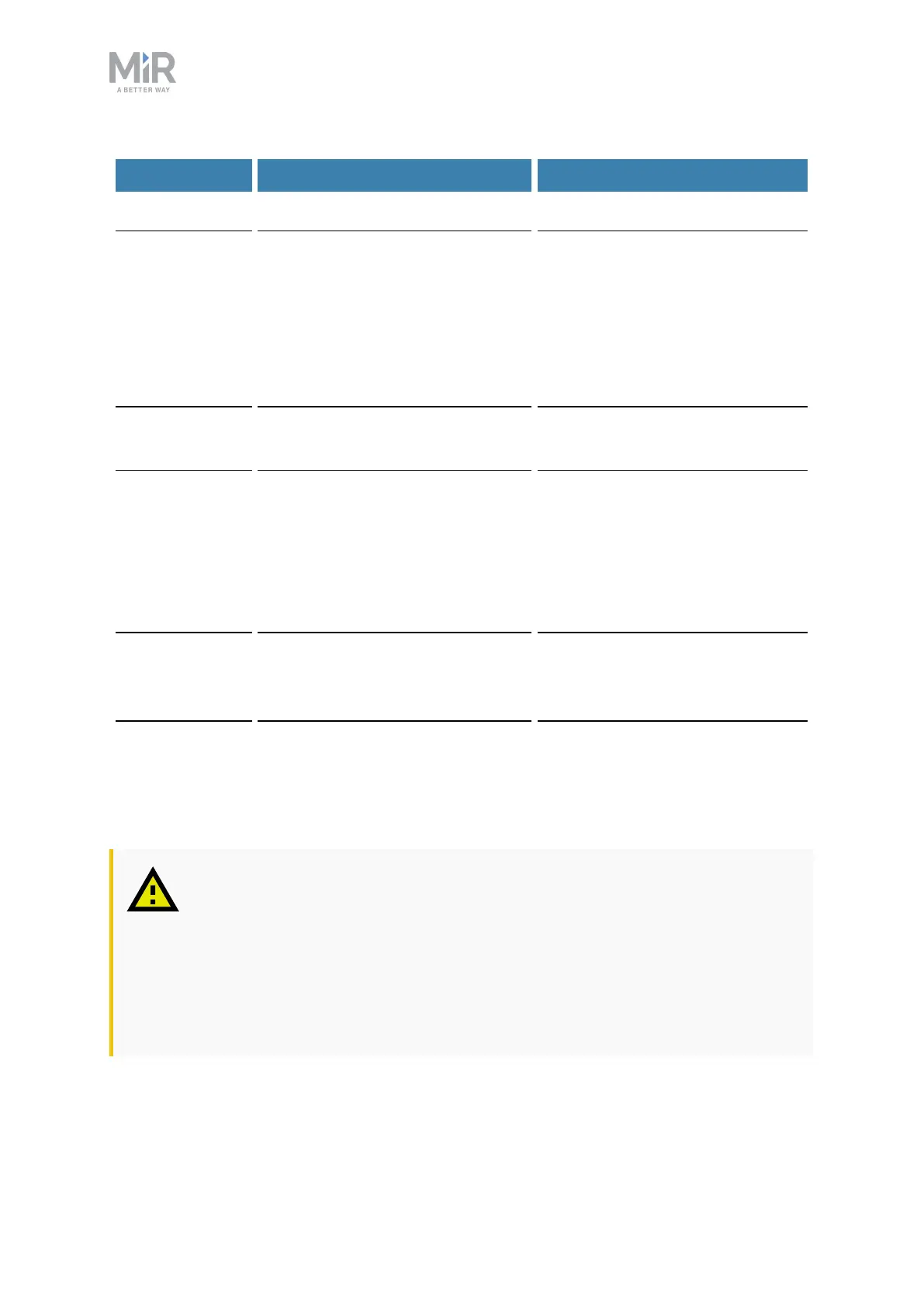

Part Maintenance Interval

it is intact.

3D cameras Check for visual defects, for

example cracks and scratches.

To test the cameras, see the

guide How to test if the 3D

cameras are working on MiR

robots

Check monthly, and calibrate or

replace as needed— see the

guide How to calibrate a D435

3D camera.

Proximity

sensors

Check for dust or dirt, and clean

with a swab.

Check weekly.

Manual brake

release switch

Check if the Manual brake

release switch functions by

releasing the brakes and pushing

the robot gently forward.

Remember to enable the brakes

again when done.

Check monthly, and replace as

needed.

Safety marking

on the floor

Check if the safety markings

around operating hazard zones

are intact and visible.

Check every six months, and

replace as needed.

Safety stickers

and nameplate

Check if the safety stickers,

identification label, and

nameplate on the robot are still

intact and visible.

Check every six months, and

replace as needed.

CAUTION

If the robot has been impacted, it may be structurally damaged, causing a risk

of malfunction and injury to personnel.

• If you suspect the robot has suffered any damage, you need to conduct a

thorough inspection to ensure that the robot's strength and structure is not

compromised.

Loading...

Loading...