74

Adjustment of the output torque (current) of the motor

4.3.4 Stall prevention operation

(Pr. 22, Pr. 23, Pr. 48, Pr. 49, Pr. 66, Pr. 148, Pr. 149, Pr. 154, Pr. 156, Pr. 157)

The above parameters can be set when Pr. 160 User group read selection = "0". (Refer to page 185)

*1 This parameter allows its setting to be changed during operation in any operation mode even if "0 (initial value) or 1" is set in Pr. 77 Parameter write

selection.

*2 When Pr. 570 Multiple rating setting = "1", performing inverter reset and all parameter clear changes the initial value and setting range. (Refer to

page 79)

This function monitors the output current and automatically changes the output frequency to prevent the inverter

from coming to trip due to overcurrent, overvoltage, etc. It can also limit stall prevention and fast-response

current limit operation during acceleration/deceleration, driving or regeneration.

Stall prevention

If the output current exceeds the stall prevention operation level, the output frequency of the inverter is

automatically varied to reduce the output current.

Also the second stall prevention function can restrict the output frequency range in which the stall prevention

function is valid.

Fast-response current limit

If the current exceeds the limit value, the output of the inverter is shut off to prevent an overcurrent.

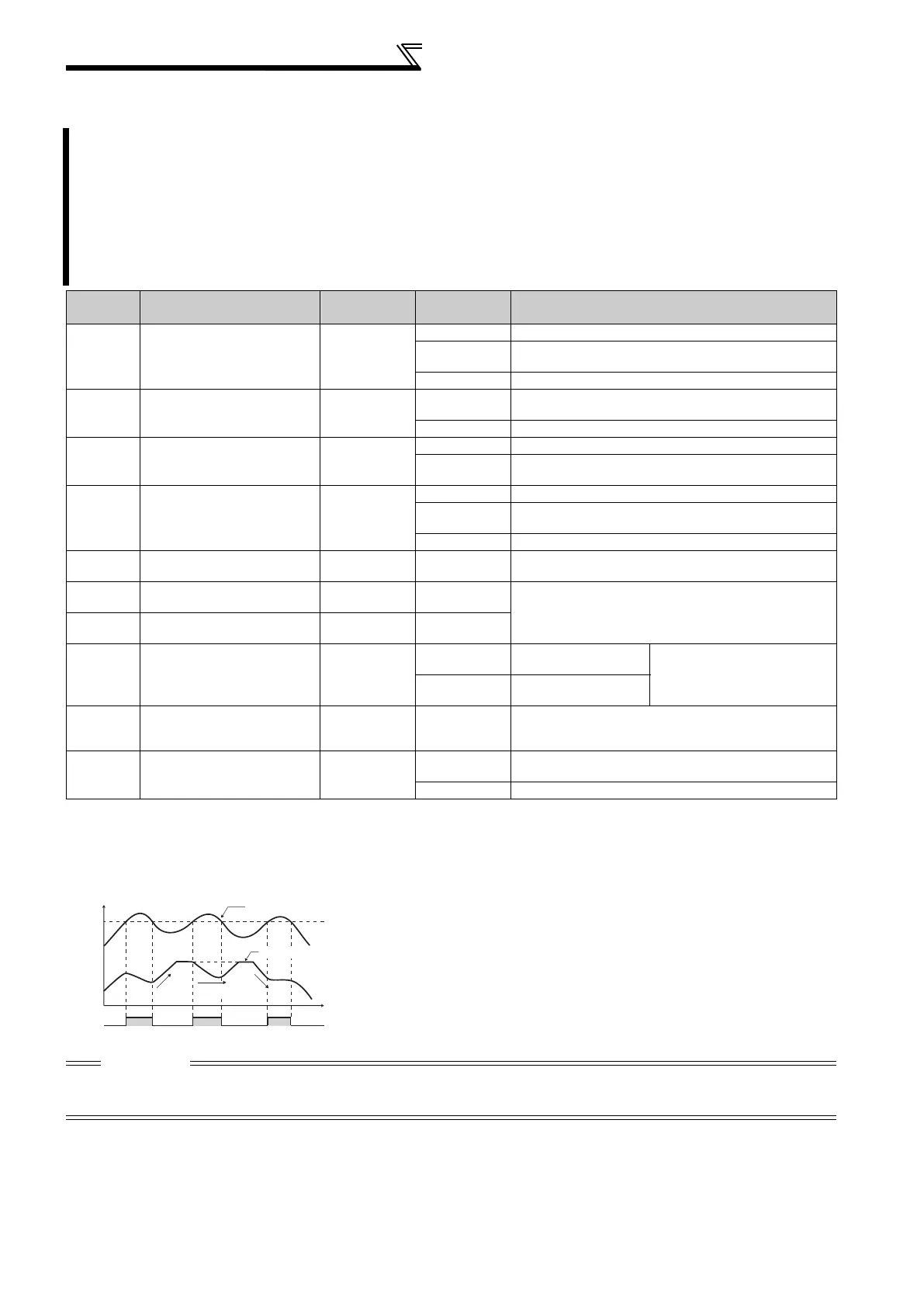

Parameter

Number

Name Initial Value

Setting

Range

Description

22 *1

Stall prevention operation

level

110%

*2

0 Stall prevention operation selection becomes invalid.

0.1 to 120%

*2

Set the current value at which stall prevention

operation will be started.

9999 Analog variable

23

Stall prevention operation

level compensation factor

at double speed

9999

0 to 150%

*2

The stall operation level can be reduced when

operating at a high speed above the rated frequency.

9999 Constant according to Pr. 22

48

Second stall prevention

operation current

110%

*2

0 Second stall prevention operation invalid

0.1 to 120%

*2

The second stall prevention operation level can be

set.

49

Second stall prevention

operation frequency

0Hz

0 Second stall prevention operation invalid

0.01 to 400Hz

Set the frequency at which stall prevention operation

of Pr. 48 is started.

9999 Pr. 48 is valid when the RT signal is ON.

66

Stall prevention operation

reduction starting frequency

50Hz 0 to 400Hz

Set the frequency at which the stall operation level is

started to reduce.

148

Stall prevention level at 0V

input

110%

*2 0 to 120% *2

Stall prevention operation level can be changed by

the analog signal input to terminal 1.

149

Stall prevention level at

10V input

120%

*2 0 to 120% *2

154

Voltage reduction

selection during stall

prevention operation

1

0

With voltage

reduction

You can select whether to use

output voltage reduction

during stall prevention

operation or not.

1

Without voltage

reduction

156

Stall prevention operation

selection

0

0 to 31,

100, 101

You can select whether stall prevention operation and

fast-response current limit operation will be performed

or not.

157 OL signal output timer 0s

0 to 25s

Set the output start time of the OL signal output when

stall prevention is activated.

9999 Without the OL signal output

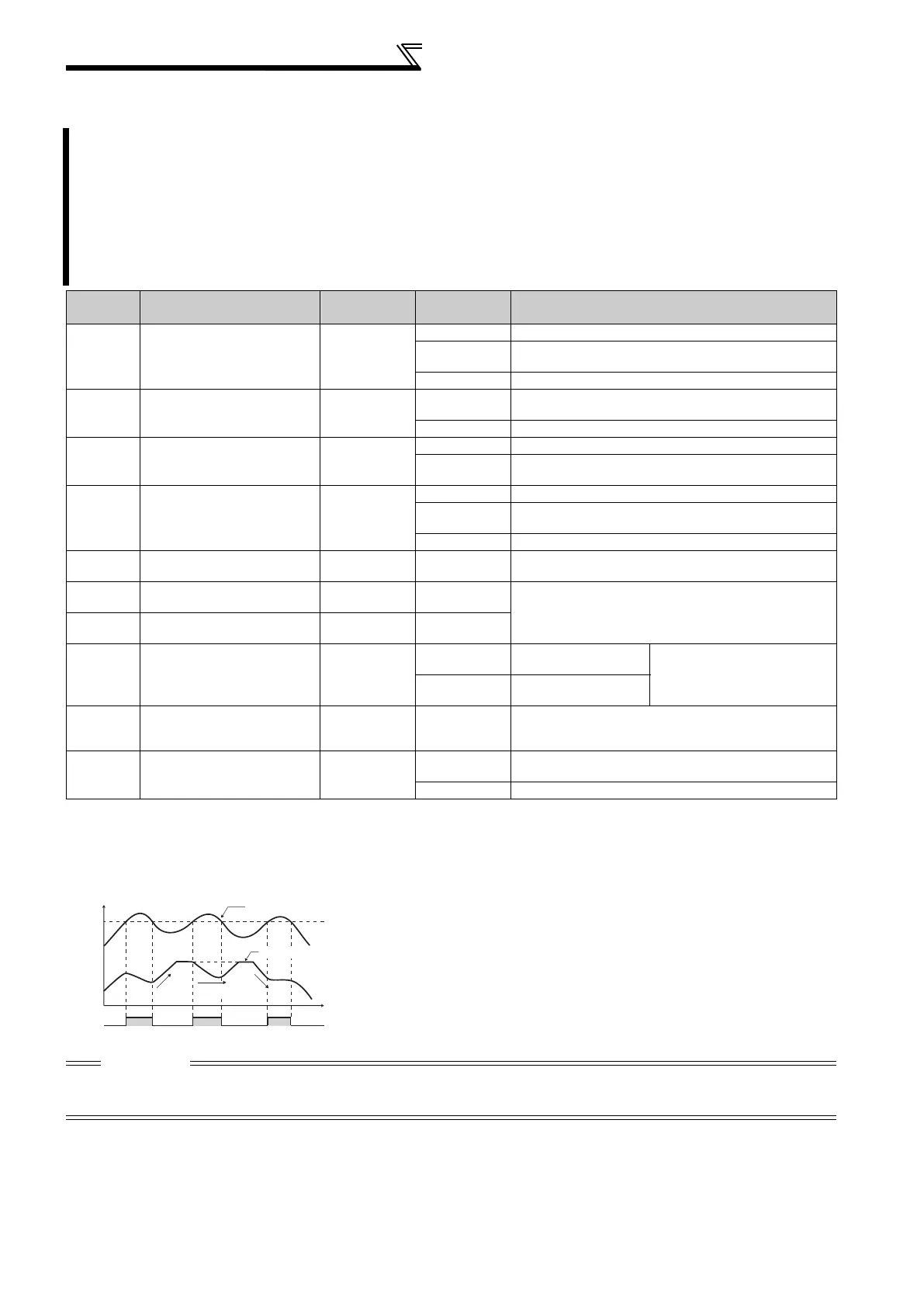

(1) Setting of stall prevention operation level (Pr. 22)

Set in Pr. 22 the ratio of the output current to the rated inverter current at

which stall prevention operation will be performed. Normally set 110%

(initial value).

Stall prevention operation stops acceleration (makes deceleration) during

acceleration, makes deceleration during constant speed, and stops

deceleration during deceleration.

When stall prevention operation is performed, the OL signal is output.

CAUTION

If an overload status lasts long, an inverter trip (e.g. electronic thermal relay function (E.THM)) may occur.

When Pr. 156 has been set to activate the fast-response current limit (initial setting), the Pr. 22 setting should not be higher than

140%. The torque will not be developed by doing so. (When Pr. 570 = "1")

Stall prevention operation example

Pr.22

OL

Output current

Output frequency

Acceleration

Constant

speed

Deceleration

Time

Loading...

Loading...