275

PID control

4.20.4 Second PID function (Pr.753 to Pr. 758, Pr.765 to Pr.769)

When the RT signal is ON and Pr. 753 Second PID action selection 9999, PID control is commanded by the

second function parameters.

When Pr. 753 = 9999, normal PID control is performed even if the second functions are valid.

When the control method is switched from the second PID control to the normal PID control, the integral value is

estimated. The integral value is estimated by calculating the integral term with the output frequency and the P

term. This method is same as when the control method changes to PID control when the frequency reaches the

automatic switchover frequency.

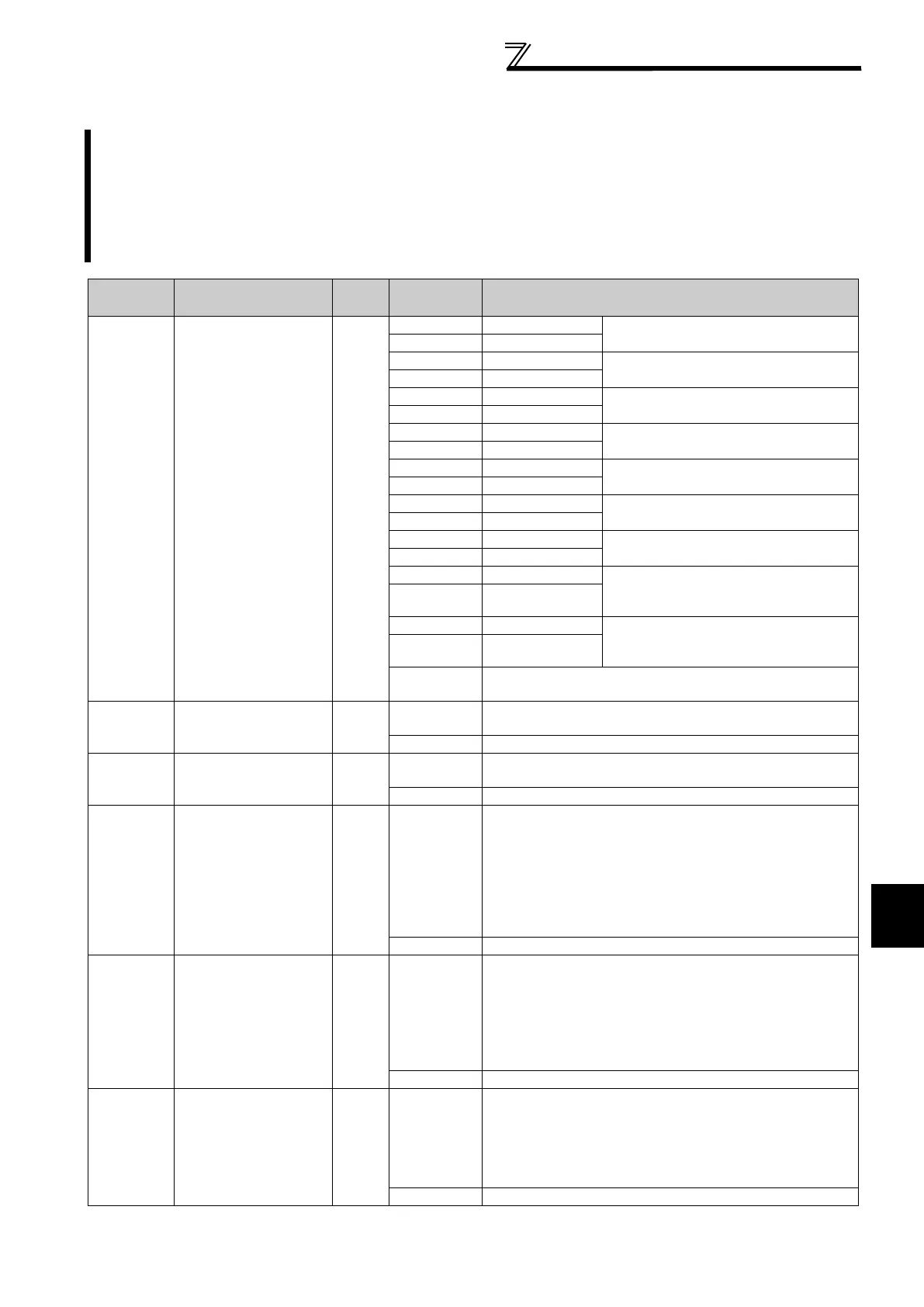

Parameter

Number

Name

Initial

Value

Setting

Range

Description

753

Second PID action

selection

9999

10

*2, 110 PID reverse action

Deviation value signal input

(terminal 1

*4)

11

*2, 111 PID forward action

20

*2, 120 PID reverse action

Measured value (terminal 4

*5)

Set point (terminal 2

*4 or Pr. 133)

21

*2, 121 PID forward action

40

*2, 140 PID reverse action

Measured value (terminal 4

*5)

Set point input (L

ON

W

ORKS

, CC-Link, BACnet)

41 *2, 141 PID forward action

50

*2 PID reverse action

Deviation value signal input

(L

ON

W

ORKS

, CC-Link, BACnet)

51 *2 PID forward action

60

*2 PID reverse action

Measured value, set point input

(L

ON

W

ORKS

, CC-Link, BACnet)

61 *2 PID forward action

70

*6 PID reverse action

Deviation value signal input

(PLC function)

71

*6 PID forward action

80

*6 PID reverse action

Measured value, set point input

(PLC function)

81

*6 PID forward action

90

*6 PID reverse action Deviation value signal input

(PLC function)

(Not reflected to the inverter frequency)

91

*6 PID forward action

100

*6 PID reverse action Measured value, set point input

(PLC function)

(Not reflected to the inverter frequency)

101

*6 PID forward action

9999

Normal PID control is performed regardless of the second PID

control parameter settings.

754

Second PID control

automatic switchover

frequency

9999

0 to 400Hz

Set the frequency at which the control is automatically

changed to PID control while the RT signals is ON.

9999 Without second PID control automatic switchover function

755

*1

Second PID action set

point

9999

0 to 100%

*3

Set the set point for PID control, which is performed while the

RT signal is ON.

9999 Terminal 2 input is the set point while the RT signal is ON.

756

*1

Second PID

proportional band

100%

0.1 to 1000%

Set the proportional band for PID control, which is performed

while the RT signal is ON.

If the proportional band is narrow (parameter setting is small),

the manipulated variable varies greatly with a slight change of

the measured value. Hence, as the proportional band narrows,

the response sensitivity (gain) improves but the stability

deteriorates, e.g. hunting occurs.

Gain Kp = 1/proportional band

9999 Without second proportional band

757

*1

Second PID integral

time

1s

0.1 to 3600s

Set the PID integral time for PID control, which is performed

while the RT signal is ON.

When deviation step is input, time (Ti) is the time required for

integral (I) action to provide the same manipulated variable as

proportional (P) action.

As the integral time decreases, the set point is reached earlier

but hunting occurs more easily.

9999 Without second integral control

758

*1

Second PID differential

time

9999

0.01 to

10.00s

Set the PID differential time for PID control, which is performed

while the RT signal is ON.

When deviation lamp is input, time (Td) is the time required to

provide the manipulated variable of only the proportional (P)

action. As the differential time increases, greater response is

made to a deviation change.

9999 Without second differential control

Loading...

Loading...