71

Adjustment of the output torque (current) of the motor

4.3 Adjustment of the output torque (current) of the motor

4.3.1 Manual torque boost (Pr. 0, Pr. 46)

(2) Set multiple torque boost (RT signal, Pr. 46)

Use the second torque boost when changing the torque boost according to application or when using multiple

motors by switching between them by one inverter.

Pr. 46 Second torque boost is valid when the RT signal turns ON.

Purpose Parameter that must be Set Refer to Page

Set starting torque manually Manual torque boost Pr. 0, Pr. 46 71

Automatically control output current

according to load

Simple magnetic flux

vector control

Pr. 71, Pr. 80, Pr. 90 72

Compensate for motor slip to secure

low-speed torque

Slip compensation Pr. 245 to Pr. 247 73

Limit output current to prevent inverter

trip

Stall prevention operation

Pr. 22, Pr. 23, Pr. 66,

Pr. 154, Pr. 156, Pr. 157

74

Change the overload current rating

specifications

Multiple rating setting Pr. 570 79

You can compensate for a voltage drop in the low-frequency range to improve motor torque reduction in the low-

speed range.

Motor torque in the low-frequency range can be adjusted to the load to increase the starting motor torque.

The starting torque boost can be changed by switching terminals.

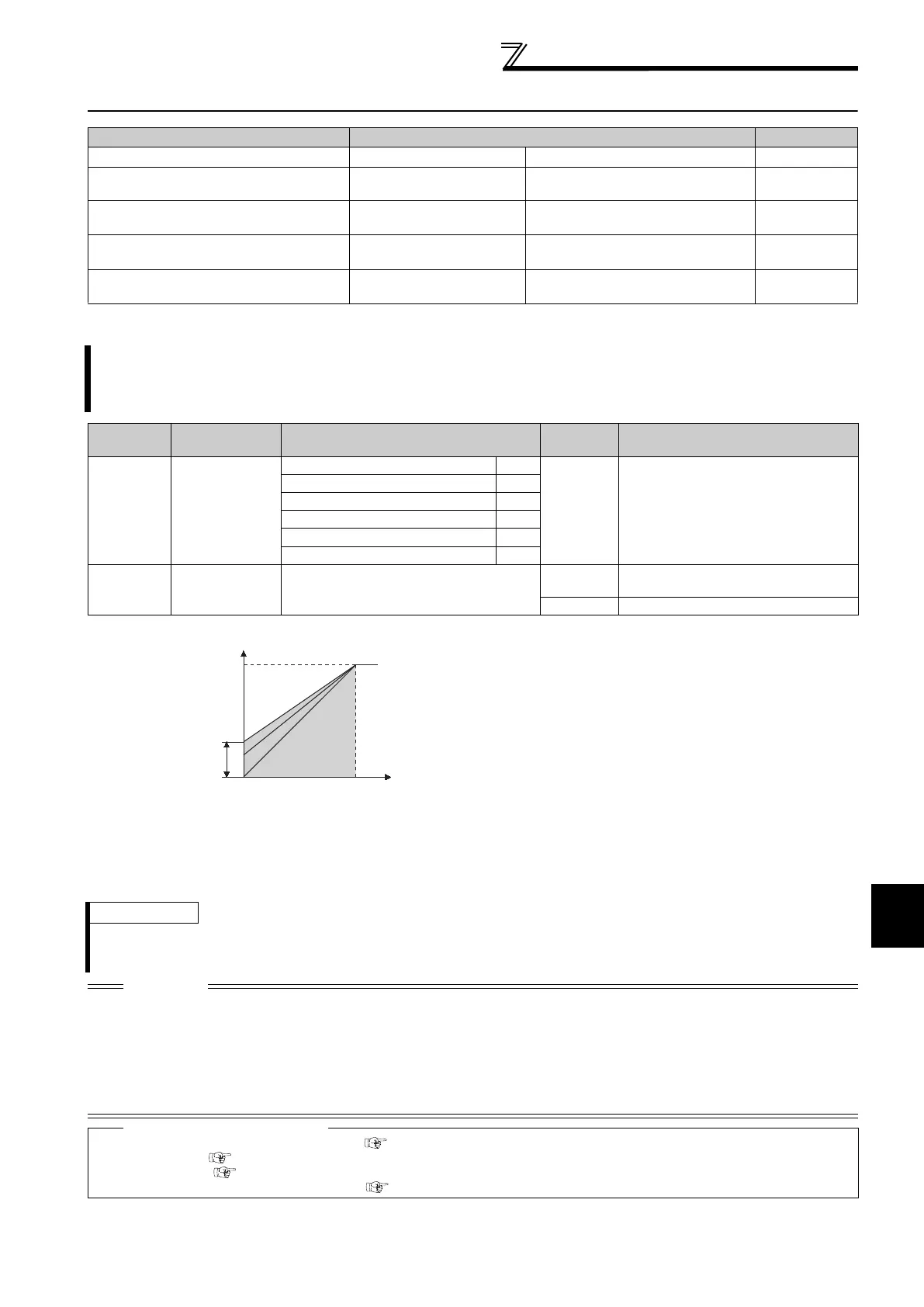

Parameter

Number

Name Initial Value

Setting

Range

Description

0 Torque boost

00023 6%

0 to 30% Set the output voltage at 0Hz as %.

00038

to

00083 4%

00126, 00170 3%

00250 to 00770 2%

00930, 01160 1.5%

01800 or more 1%

46

*1

Second torque

boost

9999

0 to 30%

Set the torque boost value when the

RT signal is ON.

9999 Without second torque boost

*1 They can be set when Pr. 160 User group read selection = "0". (Refer to page 185.)

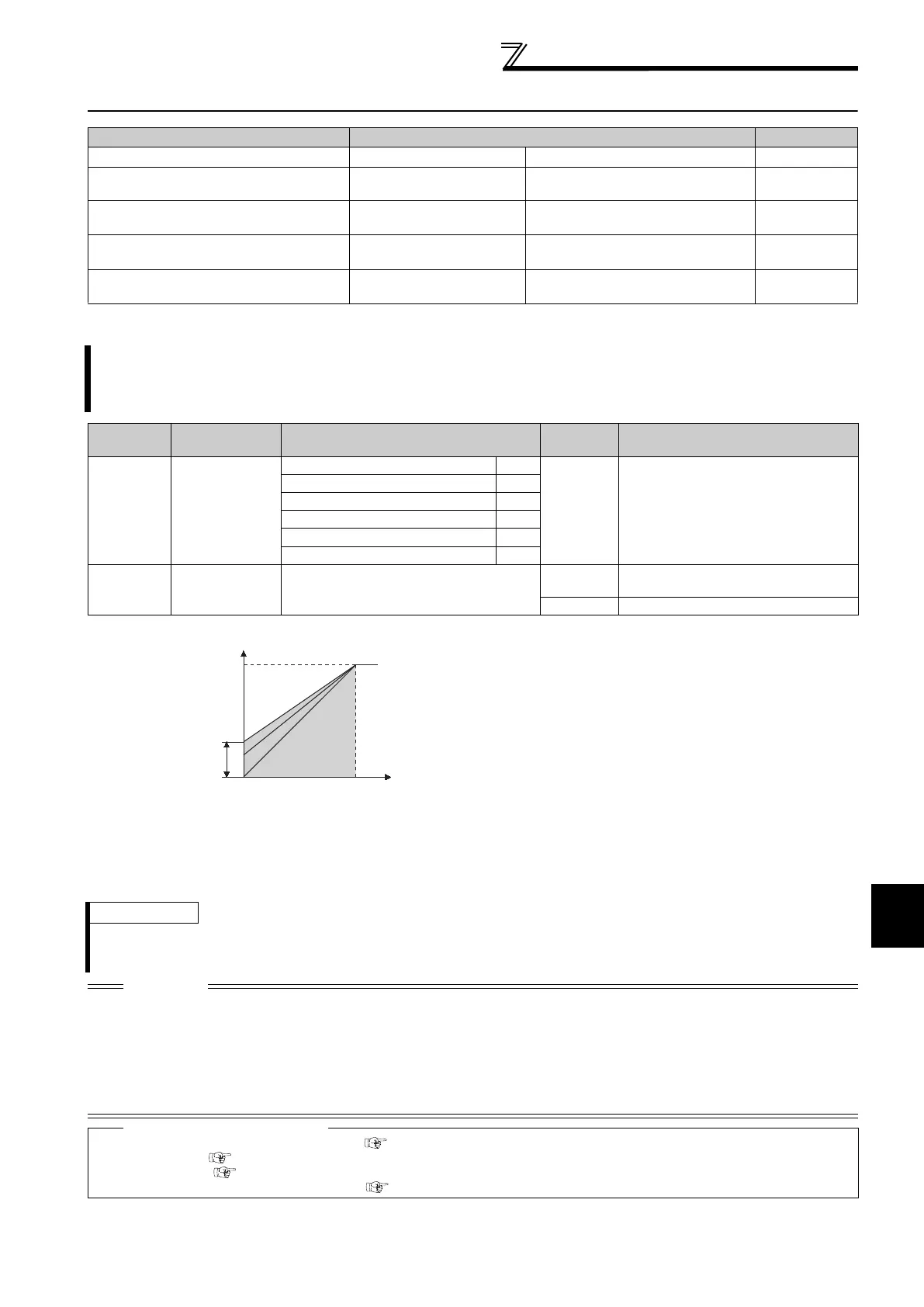

(1) Starting torque adjustment

On the assumption that Pr. 19 Base frequency voltage is

100%, set the output voltage at 0Hz in % in Pr. 0 (Pr. 46).

Adjust the parameter little by little (about 0.5%), and check

the motor status each time. If the setting is too large, the

motor will overheat. The guideline is about 10% at the

greatest.

REMARKS

The RT signal acts as the second function selection signal and makes the other second functions valid. (Refer to page 119)

The RT signal is assigned to the RT terminal in the default setting. By setting "3" to any of Pr. 178 to Pr. 189 (Input terminal function

selection), you can assign the RT signal to the other terminal.

CAUTION

Increase the setting when the distance between the inverter and motor is long or when motor torque is insufficient in the low-

speed range. If the setting is too large, an overcurrent trip may occur.

The Pr. 0 and Pr. 46 settings are valid only when V/F control is selected.

When using the inverter dedicated motor (constant-torque motor) with the 00126 or 00170, set the torque boost value to 2%. If

the initial set Pr. 71 value is changed to the setting for use with a constant-torque motor, the Pr. 0 setting changes to the

corresponding value in above.

Changing the terminal assignment using Pr. 178 to Pr. 189 (input terminal function selection) may affect the other functions. Please

set parameters after confirming the function of each terminal.

Parameters referred to

Pr. 3 Base frequency, Pr. 19 Base frequency voltage Refer to page 82

Pr. 71 Applied motor Refer to page 105

Pr. 80 Motor capacity Refer to page 72

Pr. 178 to Pr. 189 (Input terminal function selection) Refer to page 117

Output

voltage

r. 0

r.46

Setting

range

Base

frequency

0

100%

Output

frequency

(Hz)

Loading...

Loading...