Setting parameters

10/05 AWB8230-1541GB

136

Activating and deactivating PID control (PID)

With a digital input configured as PID, PID control can be switched

on and off through control signal terminals. When you activate the

PID input, PID control is disabled. The frequency inverter then

works with its standard frequency control again.

X Configure one of the digital inputs 1 to 5 as PID by entering the

value 23 under the corresponding PNU (C001 to C005).

With the digital input configured as PIDC, the integral component

of the PID control can be reset. If the PIDC input is activated, the

integral component is reset to zero.

X Configure one of the digital inputs 1 to 5 as PIDC by entering

the value 24 under the corresponding PNU (C001 to C005).

PID system deviation (OD)

The PID system deviation (e) is the difference between reference

and actual value (process variable PV).

The digital output configured as OD is activated when PID control

is active (PNU A071 = 01) and a user-definable system deviation

(PNU C044) is exceeded.The OD output remains active as long as

this limit value is exceeded.

X To configure a parameterizable digital output (11 or 12) or

signalling relay K1 as OD, define the limit value under

PNU C044 above which the OD signal is activated.

X Configure one of the digital outputs (11, 12) as OD by entering

the value 04 under PNU C021 or C022, or under PNU C026 for

signalling relay K1.

h

This function is available only when PID control is active

(PNU A071 = 01).

h

Do not switch the PID controller on and off while the

frequency inverter is in RUN mode (RUN LED is lit).

h

The Activate/Disable PID Control function is optional. If

you want PID control to be active all the time, you only

need to set PNU A071 to 01.

h

Do not reset the integral component of the PID controller

while the frequency inverter is in RUN mode (RUN LED is

lit), as this can cause overcurrent tripping and rapid

deceleration, resulting in unpredictable operating states.

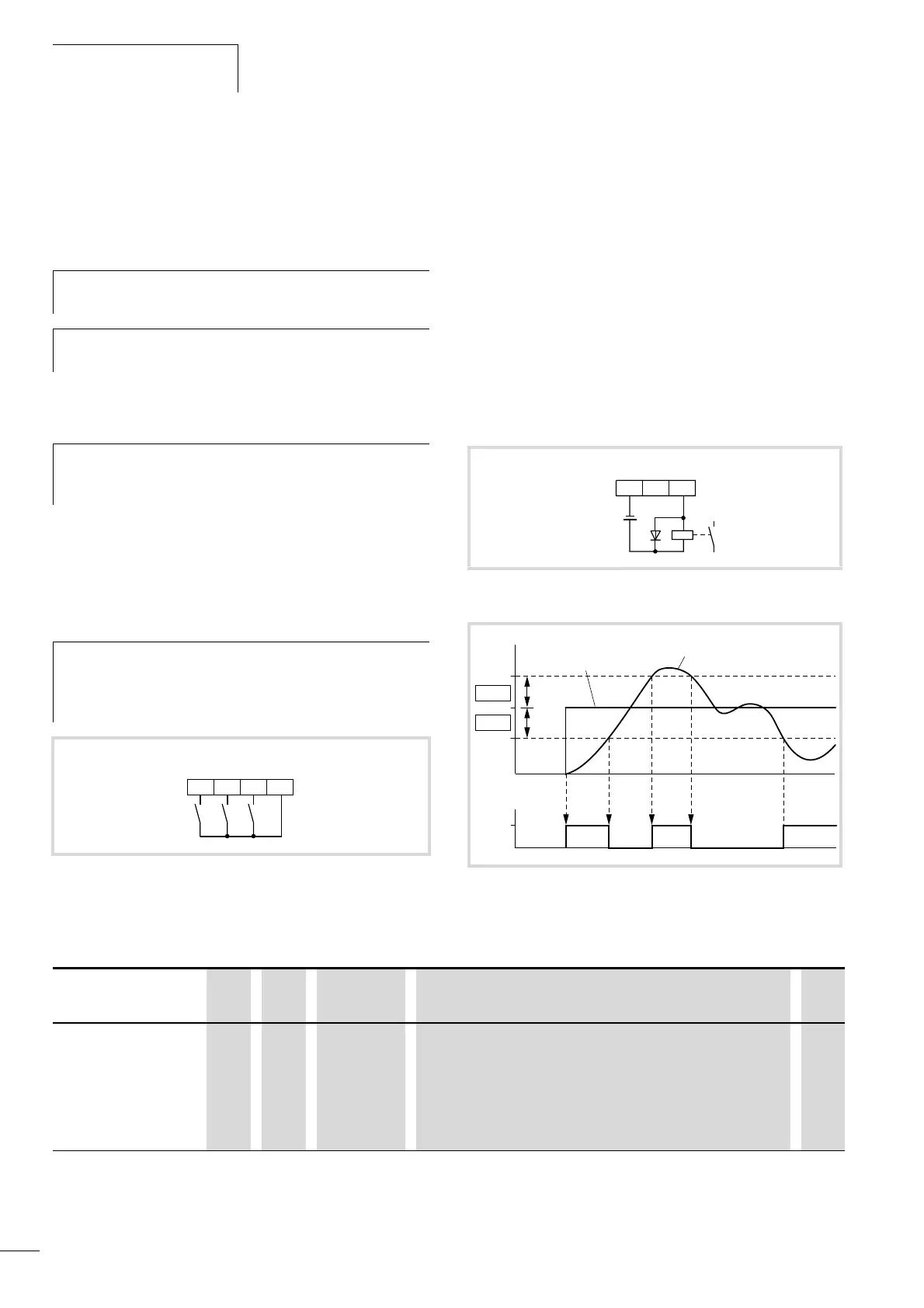

Figure 140:Digital input 1 configured as FWD (start/stop clockwise

operation), input 2 as PID (activate/deactivate switch PID

control) and input 3 as PIDC (reset integral component).

PIDC

FWD

PID

P24123

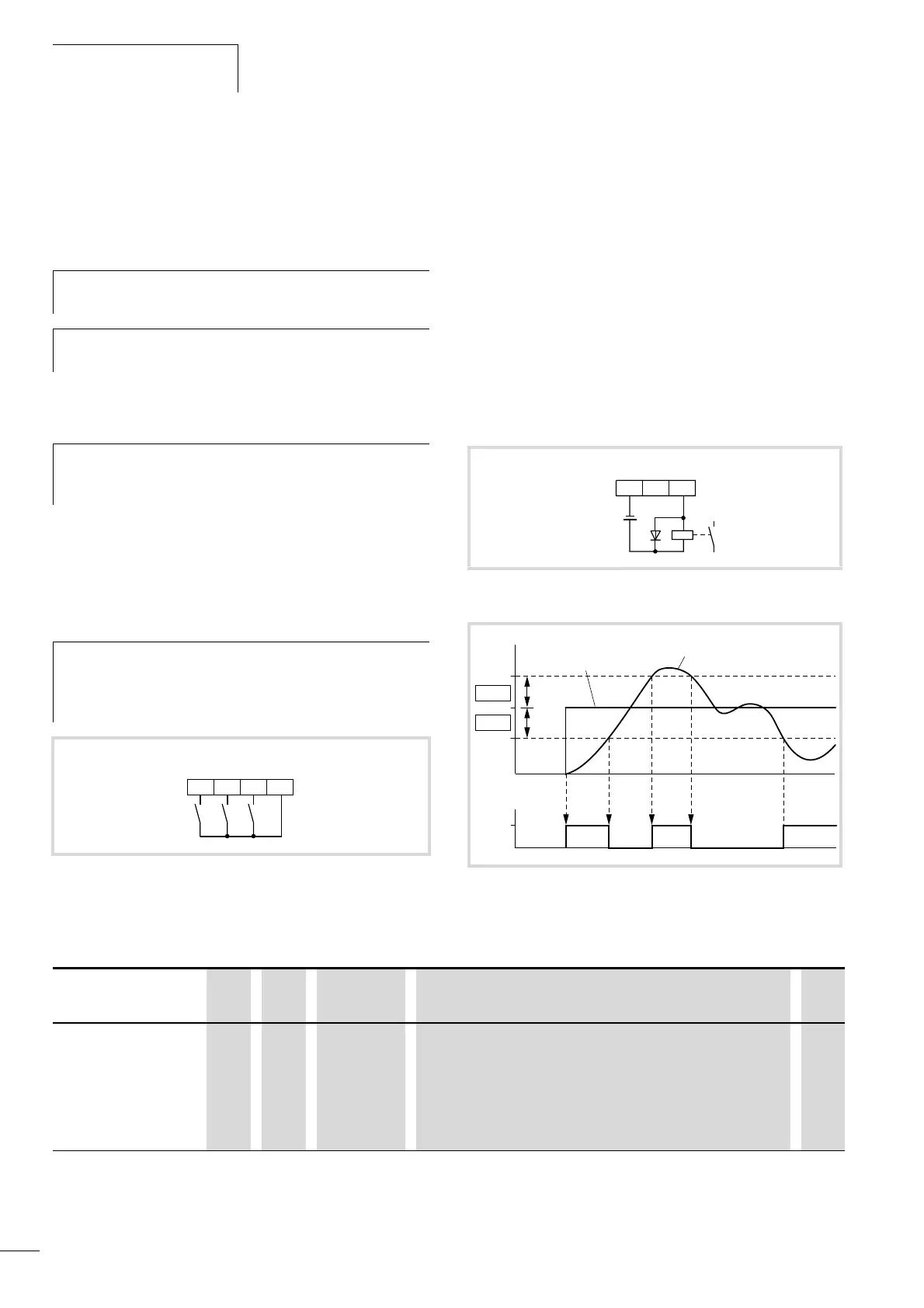

Figure 141:Digital output 11 configured as OD “PID system deviation”

Figure 142:Function chart for OD (PID system deviation)

a Reference value

b Actual value

OD

24 V

50 mA

1112CM2

OD

a

b

C044

C044

PNU Name RUN b031

= 10

Value Function DS

C044 Output

function:

Signalling

threshold,

maximum PID

control

deviation

– j 0 – 100 % If the deviation between the setpoint and actual value exceeds the

value entered here when PID control is active (PNU A071 = 01), the OD

signal is activated.

3.0

Loading...

Loading...