Use and warning instructions in compliance with EC regulations - Page 64

8.3.2.3.2. EMERGENCY PUSHBUTTON OPERATION

Press the emergency pushbutton located on the controls in the basket; the carriage engine must be turned off.

Try to carry out the movements. The platform must not move at all.

8.3.2.3.3. VERIFYING THE BASKET LEVELLING OPERATION

With the basket in a high position, manoeuvre the boom that supports the basket, changing its inclination. The basket should

automatically level itself within a few seconds, with a maximum deviation of 5° from the horizontal axis. In case the basket

fails to properly level itself, contact the Assistance department.

8.3.2.3.4. LUBRICATION OF ENTRANCE GATE HINGES (ONLY FOR GATES WITH TOTAL OPENING)

In case of a cage with gate with total opening, so as to allow perfect closing of the entrance gate over time, make sure to

apply a lubricant spray on the opening and closing hinges, spraying from the outside, without disassembling the hinges. If

the cage does not close correctly on its own, contact the Assistance department.

8.3.2.4. GENERAL CHECKS

8.3.2.4.1. CHECKING THE TORQUES

You need to visually check and, in case of doubt, using a torque wrench (not supplied with the machine), the tightness of the

locking bolts of the slewing ring and of the counter-frame, as well as of the bolts of the power take-off and of the hydraulic pump.

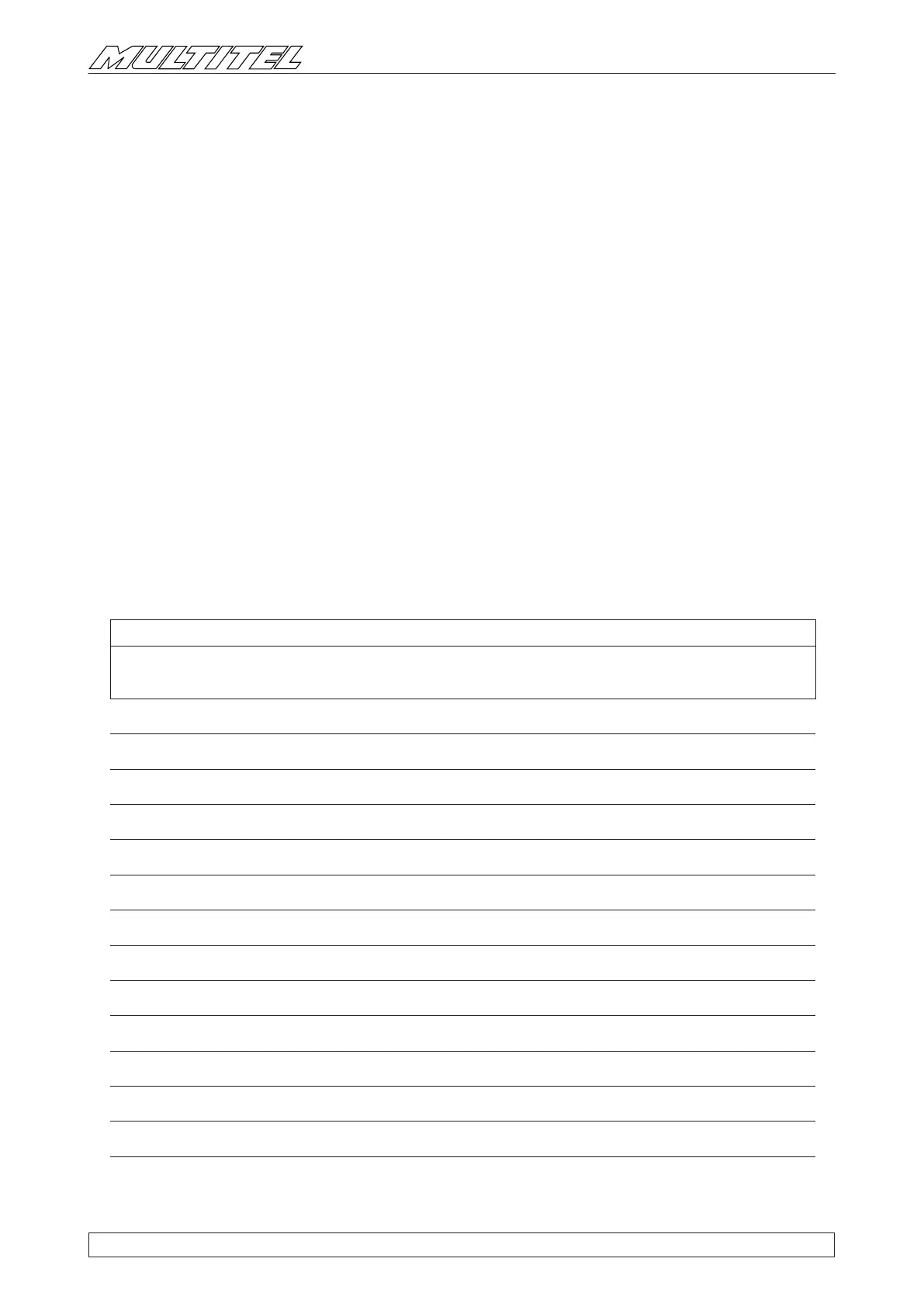

Please refer to this table for the tightening values; apply 90% of the torque value listed here below.

TABLE OF TIGHTENING TORQUES FOR TORQUE WRENCH

BOLT STRENGTH CLASS

8.8 10.9 12.9

M5 threaded diameter 5.5 8.0 9.3

M6 threaded diameter 9.3 13.9 16.2

M8 threaded diameter 22.5 33 38

M10 threaded diameter 45 67 78

M12 threaded diameter 78 117 135

M14 threaded diameter 126 184 216

M16 threaded diameter 193 279 333

M18 threaded diameter 270 387 459

M20 threaded diameter 387 558 648

M22 threaded diameter 522 747 873

M24 threaded diameter 666 954 1116

M27 threaded diameter 990 1395 1665

M30 threaded diameter 1350 1890 2250

Loading...

Loading...