Industrial gear units – Operating and Assembly Instructions

68 B 1050 en-1819

5 Service and maintenance

Pos: 15 1 /Anlei tung en/G etrieb e/5. In spekti on un d Wartu ng/Ins pek tions - un d W artu ngsi nter val le [B1 050] @ 2 7\mod_1551099994186_388.docx @ 2490540 @ 2 @ 1

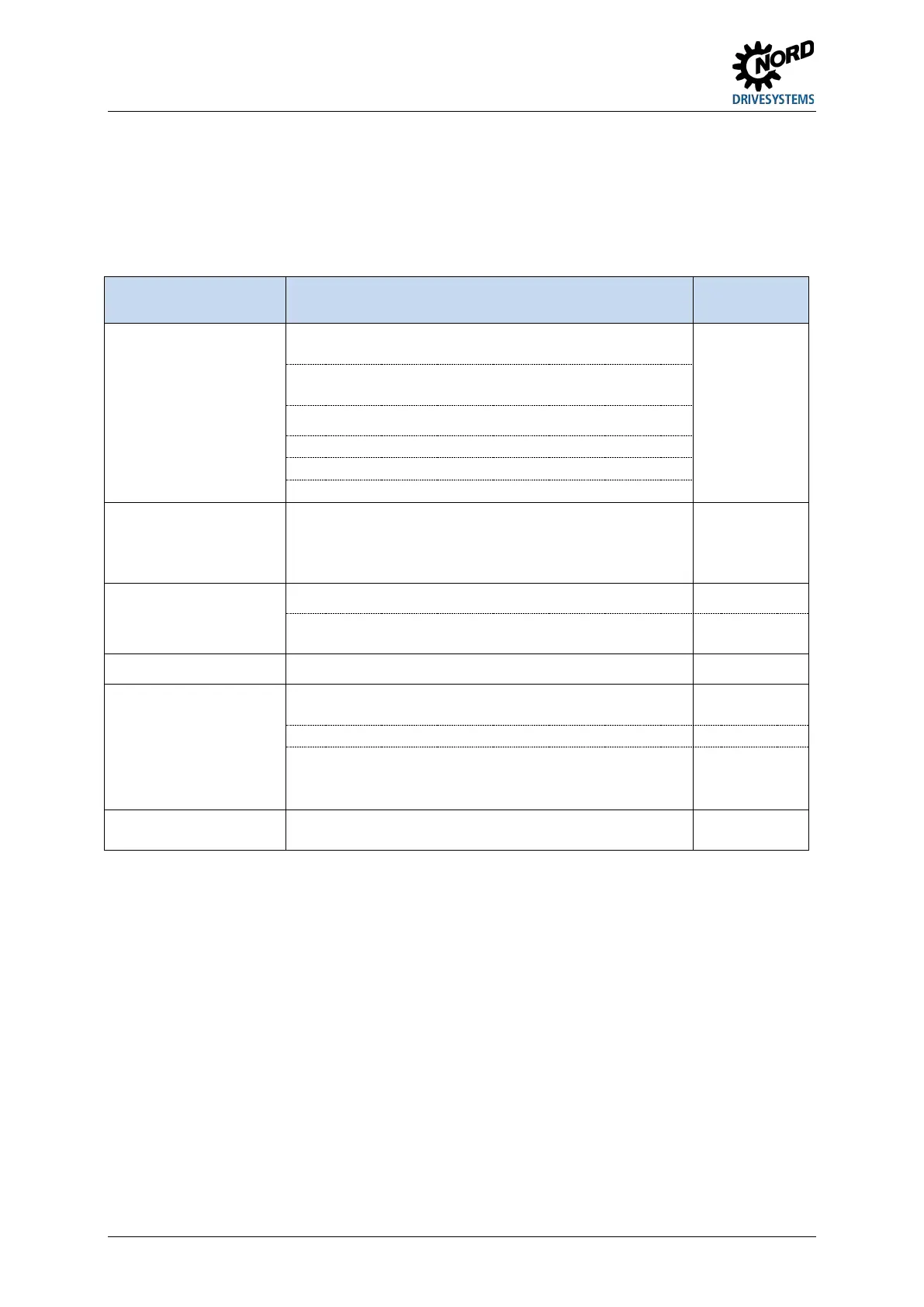

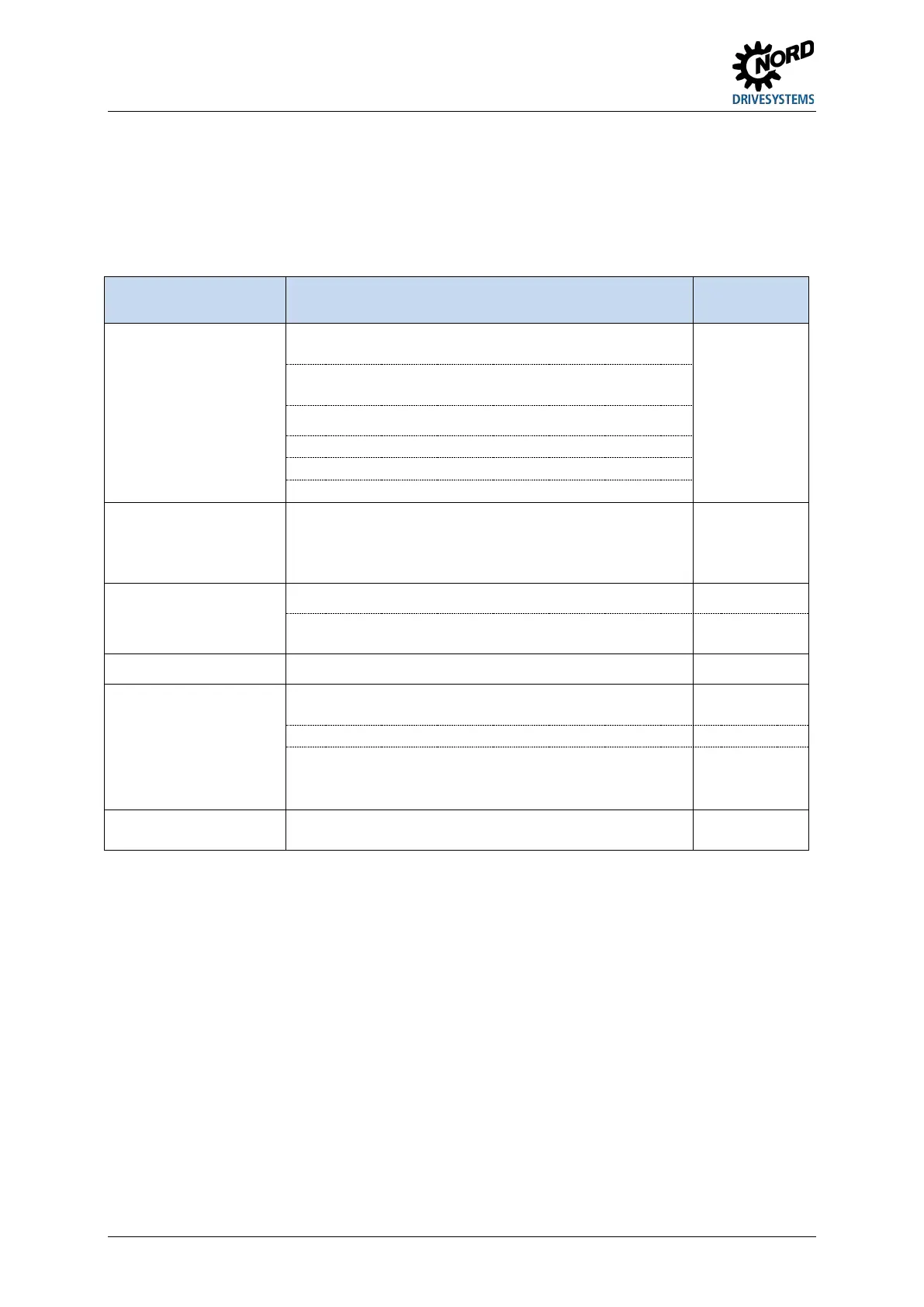

5.1 Service and Maintenance Intervals

Service and Maintenance

Intervals

Service and maintenance work

Information

see Section

manufacturer's details

• Option PT100: Check the function and measurement

accuracy; recalibrate as necessary

Manufacturer's

documentation

• Option LC/LCX: Check the function and measurement

accuracy of the pressure monitor, recalibrate as necessary

• Option CS1: Service the oil / water cooler

• Option CS2: Service the oil / air cooler

• Couplings: Service the drive and output couplings

> 6 months

• Regularly check the protective coating on unpainted and

painted surfaces

• Check the condition of the oil

• Check the seals

3.3

Every 100 operating hours,

but at least weekly

• Visual inspection for leaks

• Check the gear unit for unusual running noises and

vibrations

After 500 operating hours

• First oil change after commissioning

• Option FAN: Check the air cooler / gear unit for dirt and dirt

deposits

• Option CS2: • Check the heat exchanger for dirt

• Check the covers and the attachment adapters for dirt and

dirt deposits

At least once within

3 months

• Belt drive option: Inspect the pulleys and belts for wear and

condition. (Profile gauges)

5.2.16

Loading...

Loading...