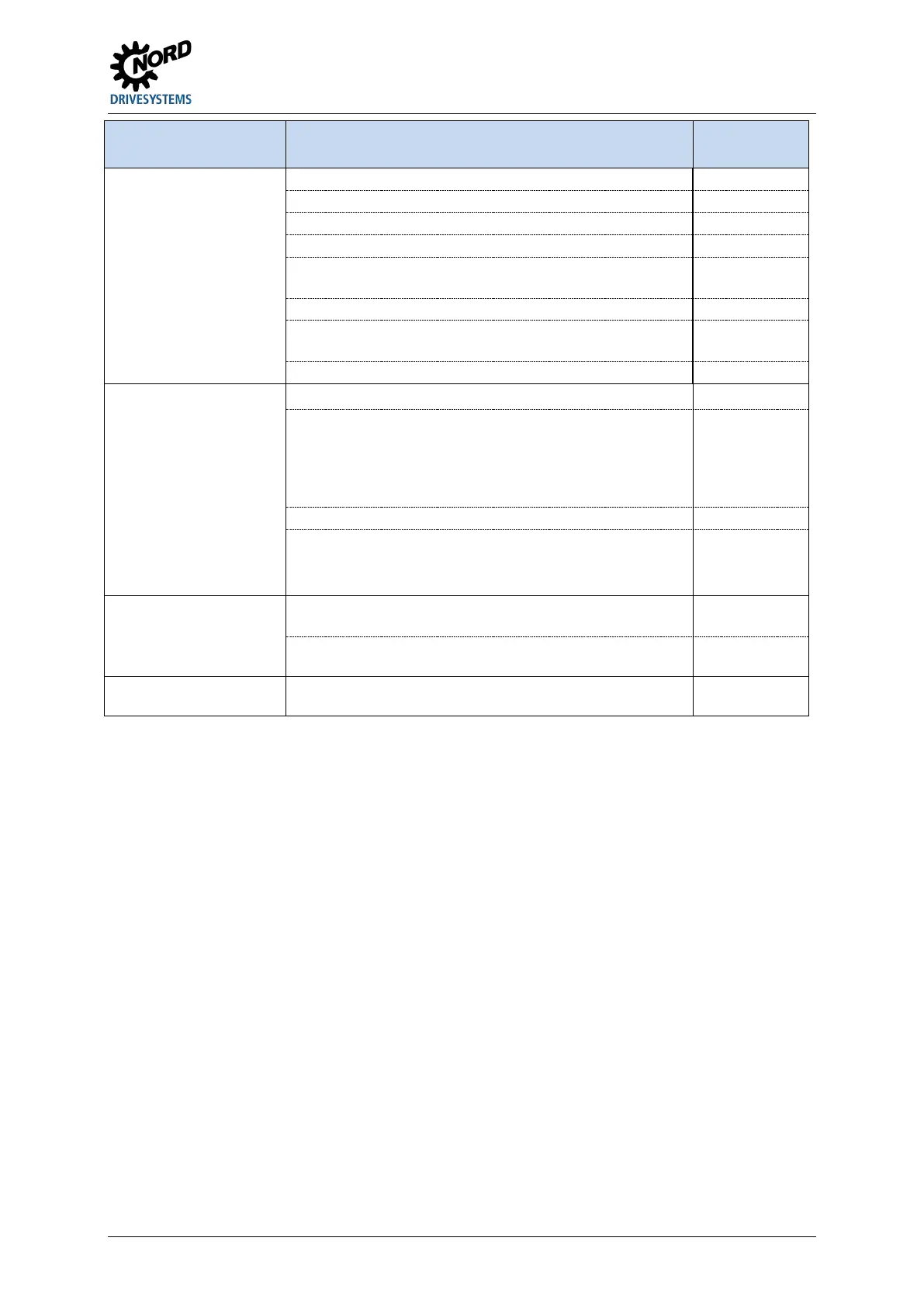

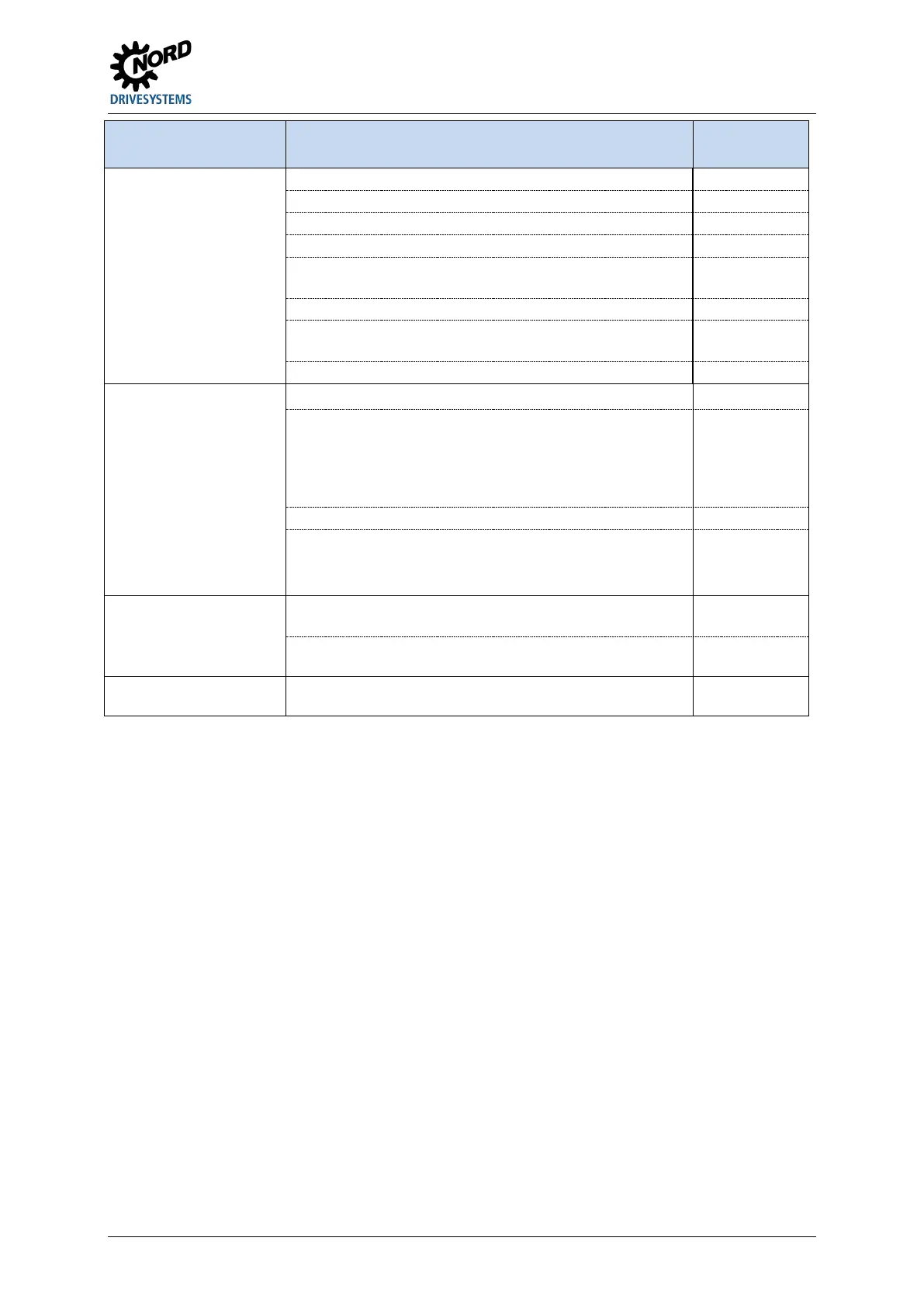

5 Service and maintenance

B 1050 en-1819 69

Service and Maintenance

Intervals

Service and maintenance work

Information

see Section

Every 2500 operating

hours,

but at least every six

months

• Visual inspection of shaft sealing ring

• Check the oil level and oil condition

• Clean or replace the vent

• Option D, ED: Visual inspection of the rubber buffers

• Option LC, LCX, CS1, CS2, OT: Visual inspection of hoses

and pipes

• Option CS1, CS2, LC, LCX: Check the oil filter

• Option VL2/3/4/6 KL2/3/4/6: Re-lubricate the bearings in the

output flange and remove excess grease

• Taconite option: Re-greasing

For operating temperatures

up to 80 °C:

Every 10000 operating

hours,

but at least every 2 years

Higher temperatures

reduce the oil change

intervals

• Replace shaft sealing rings if worn

• Oil change (the interval is double for filling with synthetic

products) reduction of the lubricant change interval for

extreme operating conditions (high humidity, aggressive

environments and large temperature fluctuations)

5.2.13

• Option CS1, CS2, LC, LCX: Replace the oil filter 5.2.10

• Option CC: Check the cooling coil for deposits (fouling)

Every 20000 operating

hours,

but at least every 4 years

• Re-grease the bearings in the gear unit (only for

SK5..07- SK6..07 and installation position M5/M6)

• Option LC, LCX, CS1, CS2, OT: Replace hose lines

At least every 10 years

Table 12: Service and Maintenance Intervals

Pos: 15 2 /Allg emein/ Allg emeing ültig e Mod ule/---------Sei tenumbr uch ko mpakt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

Loading...

Loading...