5 Service and maintenance

B 1050 en-1819 73

Pos: 16 4 /Anlei tung en/G etrieb e/5. In spekti on un d Wartu ng/Öls tand_ 01 [B1 050, B2 050] @ 2 8\mod_1551272004198_388.docx @ 2492302 @ 3 @ 1

5.2.6 Oil level

The installation position must comply with the version on the type plate.

Pos: 16 5 /Anlei tung en/G etrieb e/5. In spekti on un d Wartu ng/Öls tand_ 02 [B1 050] @ 31\mod_1553008507411_388.docx @ 2514063 @ @ 1

The oil level may only be checked when the gear unit is at a standstill and has cooled down. The oil

temperature should be between 20 °C and 40 °C. The gear unit must be secured to prevent accidental

activation.

Pos: 166 /Anleitungen/Getriebe/5. Inspektion und Wartung/Ölstand_03 [B1050, B2050] @ 31\mod_1553008518347_388.docx @ 2514104 @ @ 1

With double gear units and gears with auxiliary drive (Option: WX) the oil level must be checked on

both gear units. For auxiliary drives with freewheeling couplings the oil level in the attachment cylinder

must also be checked.

Oil level checks and top-ups may be necessary for attached couplings. In this case, the

manufacturer's documentation must be observed.

If necessary, the oil level must be corrected with the type of oil which is stated on the type plate, or the

appropriate quantity of oil must be drained off.

If possible, filling should be carried out via the vent position.

The positions of the oil measuring device, the vent and the oil drain can be obtained from the specific

dimension sheet for the order.

Pos: 16 7 /Anlei tung en/G etrieb e/5. In spekti on un d Wartu ng/Öls tand_ 04-Öl stan dssc hra ube [ B105 0, B 205 0] @ 31 \mod_1553008529510_388.docx @ 2514145 @ 4 @ 1

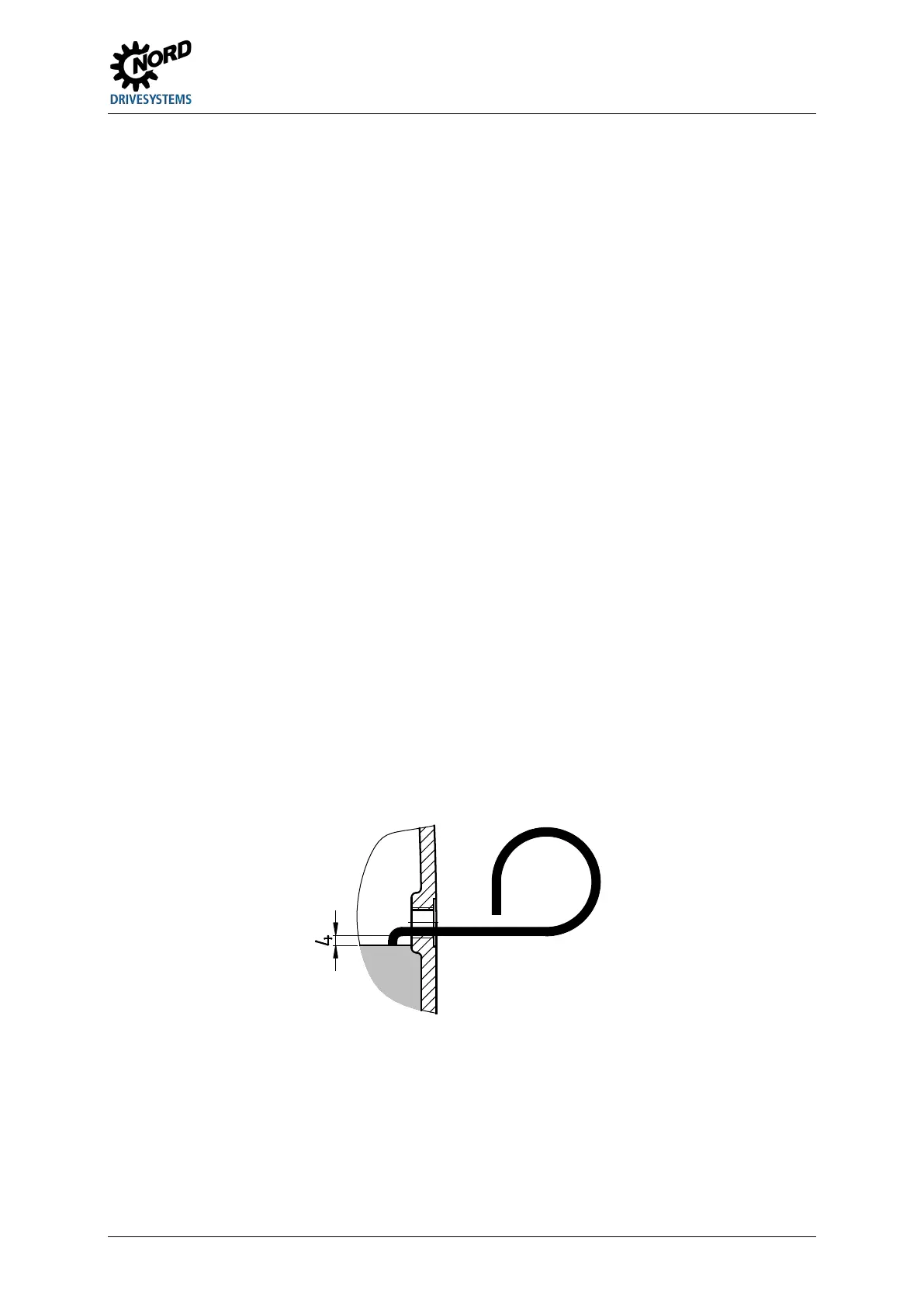

5.2.6.1 Oil level screw

1. The corresponding oil level screw must be screwed out.

2. Check the oil level in the gear unit with the dipstick supplied (Part No.: 2830050), as shown in Fig.

21. To do this, the part of the dipstick which is submerged in the oil must be held vertically. The

maximum oil level is the lower edge of the oil level hole. The minimum oil level is approx. 4 mm

below the lower edge of the oil level hole. The dipstick then just dips into the oil.

3. If the integrated seal of the oil level screw is damaged, a new oil level screw must be used or the

thread cleaned and coated with securing adhesive, (e. g. Loctite 242, Loxeal 54-03) prior to

insertion.

4. Fit the oil level screw together with the sealing ring and tighten to the correct torque (See Section

7.4 "Torque values").

Figure 27: Checking the oil level with a dipstick

Pos: 16 8 /Allg emein/ Allg emeing ültig e Mod ule/---------Sei tenumbruch kompakt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

Loading...

Loading...